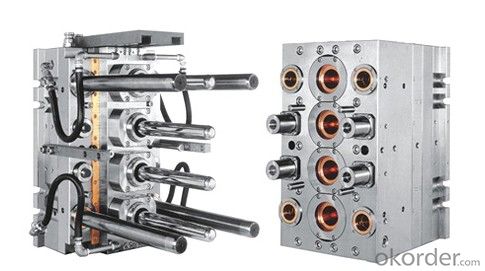

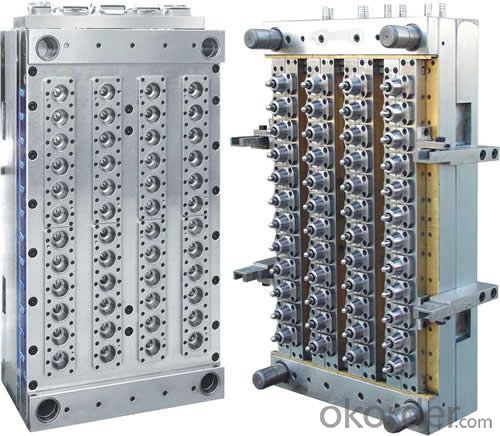

PET Mould and Parts with Hot Runner System Professinal Preform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PET Mould and Parts with Hot Runner System Professinal Preform

pecifications

Mould steel : DIN 2316,S136

Product material:steel

size:customized

Process:injection molding

Colour:as customer's requirements

| Mould Base | LKM,HASCO,DME |

| Cavity/core material | 2738,2343,S130,2344,718,8407,S136,P20,KD-61,NAK80,H13 ect |

| Cavity QTY | Single-cavity/Muti-cavity |

| Runner | Yudo cold/hot runner |

| Gate | Submarie gate,side/edge gate |

| Mould lifetime | 500,000 shots |

| Plastic part material | PC,PA,ABS,PVC,PA66+GF,TPE,SAN,POM.etc |

| Lead time | 20-40days based on different products |

| Package | Wooden cases or cartons |

| Port | Shenzhen |

| Design sofeware | UG/CAD/PROE |

Our Services

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

Product Description

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

- Q: How many kinds of equipment can be used to open the mould?

- "Open mode" is actually a general term for "die development". It consists mainly of design phase, manufacturing phase, verification phase, and commissioning phase. So, the open mode is not simply a few devices that can be done successfully.

- Q: What is a compression mold?

- The main equipment used in compression moulds is press and mold. The most commonly used are self-contained hydraulic presses, which range from dozens of tons to several hundred tons. Have lower pressure press and upper pressure press. The molds used to compress moulds are called press moulds, which are divided into three categories. Overflow mold, semi-overflow mold and mould. The main advantage of the compression mould is that it can be moulded by larger planar products and mass production, and its disadvantages are long production cycle and low efficiency.

- Q: Is the stamping tool to be used for the precision of the stamping parts? Why is that?

- The punching and falling are two different processes, although they seem to have been achieved, and the smaller ones are separated from the larger ones. The punching process, which requires the size of the detached surface of the large material, is a waste material; The drop process - the size of the small piece of material that is separated, the small material is the product. Die design of the punching process - the main die is the punch mould; The tooling that implements the localization is relatively complicated; Mold design of the blanking process - the base mode is the concave mold. Because of the emphasis on the process of punching and falling materials, the processing and placement of the material in the process of processing and resettlement are also different.

- Q: I have a glass fiber reinforced plastic mould, I want to do with resin imitation jade, don't know way it doesn't, and resin products must use silicone mold can, if use FRP mould can, what kind of release agent is good?

- I think my answer is that glass steel can be made. Imitation jade is very similar. 2 resin products are mostly made of resin mold, most of the glass fiber reinforced plastic abrasive and glass fiber reinforced plastic products are made by resin raw materials, such as trash. Stool and other civilian products and their trash abrasive abrasive tool stool mould is made of resin. But some products without rules By other materials to replace Such as silica gel, gypsum, etc Some glass fiber reinforced plastic relief also do grinding tool with mud. Their use and their advantages are now in full play. If you use a glass and steel mold, I suggest you use the yellow wax and you can buy the imported towing water.

- Q: What is a mold?What is it mainly used for

- Are the molds hard to learn? As long as you are not a complete idiot. Anyone can learn. Of course, is sure need time, anyone don't 3-5 years of time, you are difficult to achieve a master level, of course I said is plastic mold, metal mold is faster, because their forming conditions of completely different. And basic didn't also spoke on the first floor. You don't understand, can learn the process of learning, who is on the first floor said the things you want to learn, of course there are other. And future, that is to go on their own, a teacher can be in 4000 in suzhou, and hardware module can also be in 3000 or so. All I said is fitter oh, of course design will be a little bit higher.

- Q: How do you get the putty on the die?

- The putty has formed a plastic membrane, which can be cleaned by the use of an edible alkali.

- Q: Where is the mould industry in our country?

- Several large areas of the Chinese mould industry In recent years, the mould industry has developed rapidly, and its geographical distribution has become more and more formed. From the distribution of the region, the development of the pearl river delta, the Yangtze river delta and the anhui province were developed rapidly. guangdong Guangdong is the most important market for moulds in China, and it is also the biggest export and import province in China. The national mold production has more than 40% from guangdong and mould processing equipment numerical control rate and performance of equipment, mold processing technology, the production specialization level and standard level leading to other provinces. Currently, guangdong has five of the top 10 companies in the country, with the world's largest module supplier and the largest mould manufacturing plant in Asia in guangdong.

- Q: What mould steel can make injection mold?

- 5 crnimnmovsca crsca (5) the using S - Ca compound free cutting steel pin and jet metallurgy technology, improve the morphology of sulphide, distribution and the anisotropy of steel, and can ensure the distribution of sulfide in the big cross section is relatively uniform. 5 crsca steel has high hardenability, high toughness, easy cutting, advance again hard (42 HRC) are still has good processability, has a good mirror polishing performance, surface roughness after polishing can reach Ra0.040 ц m, repair welding performance is good Suitable for plastic injection mould cavity complex, compression molding, require large deformation of the plastic molding die, etc 3 cr2mo the steel is from the American AISI P20 translating into the rigid plastic die steel, and has been incorporated into the national standard (GB1299-1985) can be in 29.5 under the condition of 35 HRC hardness supply, good machining performance, excellent polishing performance. It is widely used in various countries to apply a kind of plastic mold to the compression mold and injection mould 3 cr2nimnmo the steel is a new developed on the basis of P20 steel, the steel is with strong high toughness and good machining and polishing performance can be polished to 0.020 ц m (), can be in advance hard state (30-36 HRC) processing. Apply to large plastic mold or cavity complex, request mirror polishing molds

- Q: What is the pull mold

- The drawing die is also called drawing die, which is used to pull metal plates deep into cups or curved parts. For example, small metal cups or large car body shapes.

- Q: What are the career prospects of the mould profession

- Mold professional prospect is good, although in recent years many learn this, but the market is only lack of talent, to shine on you, to learn, this is a good iron rice bowl, is willing to endure hardship, I also learn the mould... Oh, we have time to communicate

Send your message to us

PET Mould and Parts with Hot Runner System Professinal Preform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches