Plastic Injection PET Preform Mould 24 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

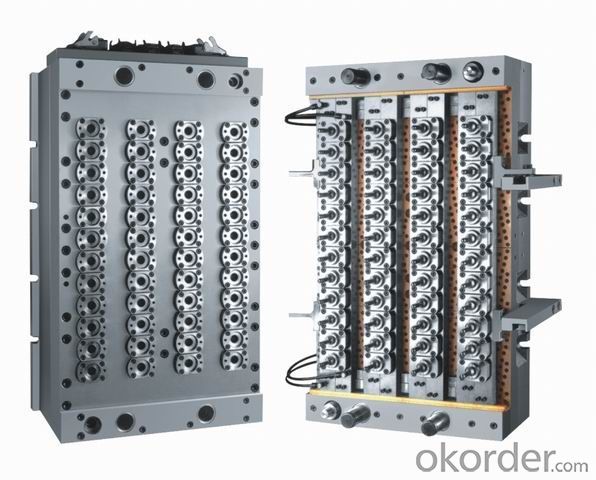

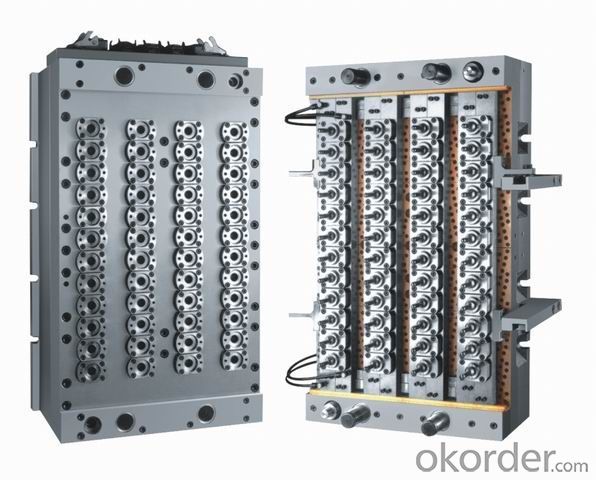

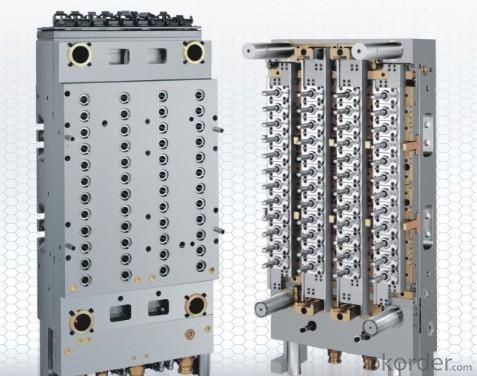

1. Structure of Multi-Cavities PP Preform Mould

Cavity, core and screw neck of steel adopt imported S136 in Sweden, and be heating treatment of hardness up to HRC48-50.

All moulds base do heat treatment of hardness up to HRC 30-35.

Advanced mould design technology:

a) Each cavity self-locks independently and using high precision JAPAN CNC SYSTEM.

b) To ensure low decent ration & precision of the product.

c) Each mould spare part be inserted with durable parts, which are interchangeable. d) In order to improve and achieve high production efficiency, we always design the best cooling system and can match a cooling machine for each mould.

Advanced & accurate valve hot runner & temperature controller, ensure reliability of production and high transparency & brightness of product.

Mould sliding use copper, bottle be achieved FOOD SECURITY standard, and mould life guarantee more than 3 million shots.

2. Main Features of Multi-Cavities PP Preform Mould

No. of Cavity | 12 Cavity | 16 Cavity | 24 Cavity | 32 Cavity | 48 Cavity | 72 Cavity |

18g(cm) | 60*37*43 | 74*37*43 | 80*50*45 | 76*60*48 | 102*60*55 | 110*86*58 |

Weight(kg) | 625 | 770 | 1300 | 1650 | 2500 | 4100 |

28(cm) | 60*37*45 | 74*37*45 | 80*50*48 | 76*60*52 | 102*60*58 | 110*86*62 |

Weight(kg) | 655 | 810 | 1310 | 1800 | 2690 | 4450 |

40(cm) | 60*37*48 | 74*37*48 | 80*50*50 | 76*60*55 | 102*60*62 | 110*86*65 |

Weight(kg) | 700 | 860 | 1360 | 1900 | 2880 | 4670 |

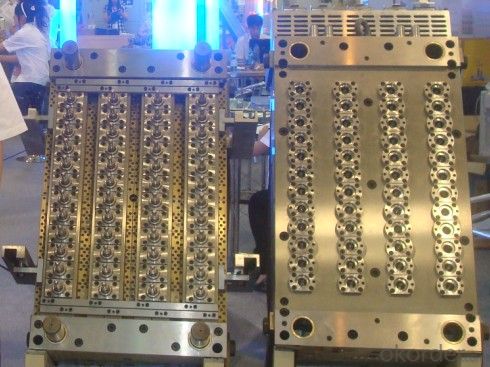

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

. Can supply with both Mold & Molded parts

. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: The role of cryogenic processing of die material

- Deep cold will change some mechanical properties, and the main effect will be as follows: Enhance the hardness and strength of the workpiece Ensure the precision of the workpiece Improve the wear resistance of the workpiece Improve the impact toughness of the workpiece Improve the internal stress distribution of the workpiece and increase the fatigue strength Improve the corrosion resistance of the workpiece.

- Q: What do you mean by plastic mold injection molding? What's the use?

- Bao subsection to the holding pressure and holding time, at the time of injection molding, about 1-2 seconds can not the mould cavity while curing fill, and then the molten plastic cooling in the mold, the volume will narrow. So after injection molding for 1 to 2 seconds, you set the pressure time and pressure pressure to continue to press the plastic into the mold, and time is the time

- Q: What is the main meaning of die mold?

- It is the fractal type, which is to divide the mold into the upper and lower, the block, the living block. That is to say that the product is split into a cavity to make the mold.

- Q: How does the die rod work? Is it through the press?

- The rigid push device usually consists of a rod, push plate, connecting rod and push piece.

- Q: Which of the dies is movable

- Add that some modules such as inversion of die before need to die out, it needs to die before installing oil cylinder, or pull board to drive out, hope my answer help you,

- Q: What is a mold bite

- The molds of molds are treated with the surface corrosion reaction of the steel surface, such as concentrated sulphuric acid, forming the skin/erosion/pear ground or other forms of grain.

- Q: What mould steel can make injection mold?

- Plastic mold with steel characteristics and USES The steel P20 belongs to low carbon steel, low strength, toughness, plasticity and weldability are good, it is mainly used for cavity is simple, small batch production of plastic mold, anti-indian method is used to manufacture the mold, then the carburizing and quenching and tempering treatment, can obtain high hardness and wear resistance, appearance of heart toughness good mould. 20 cr is one of the largest of several alloy structural steel production in our country, the application is very extensive, more than 20 steel has good hardenability, moderate strength and toughness, after carburizing treatment, has the very high hardness, wear resistance and corrosion resistance of the appropriate, as the usage of the plastic die steel with 20 steel 45 steel is China's current higher strength and better cutting workability, after proper heat treatment, can obtain a certain toughness, plastic, and wear resistance, convenient material source, generally after the conditioning, manufacturing plastic mold, is our country at present plastic mold used steel is one of the most widely steel grade 40 cr tensile strength and yield strength of the steel is higher than the corresponding carbon steel by 20%, and has good hardenability, good machinability, the steel manufacturing plastic mold and after carburizing and carbonitriding treatment, can improve the wear resistance and corrosion resistance

- Q: Make the mold with the dough

- Don't know what material are you going to make up, but the estimate is made of liquid class can be solidified material. So note that, if the material to be heated to a liquid to prevent the high temperature burn silly putty cavity (silly putty is usually made of flour and salt). In addition to prevent leakage of liquid. (recommended materials choose gesso)

- Q: What are the five systems of plastic mould?

- The plastic mould system is: pouring system, tempering system, forming parts system, exhaust system, guidance system and ejection system. The pouring system and is part of the direct contact with plastic molding parts, and with the plastic and products, is the most complicated in the mold, the biggest change, request processing smoothness and accuracy of the highest part. The above is the yu zhuo double color mould to answer for you, if help, give an adoption bai.

- Q: The wall thickness of the die is affected by the plastic parts

- For thermoplastic materials, the cooling time is added For thermosetting materials, solidification is not complete.

Send your message to us

Plastic Injection PET Preform Mould 24 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords