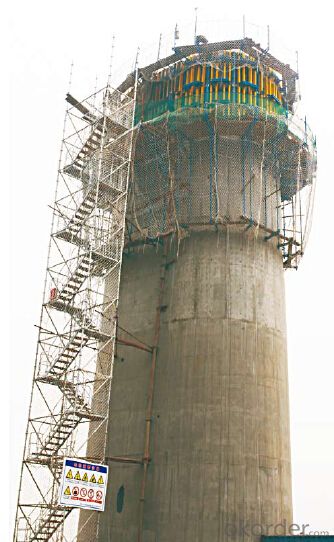

Stair tower for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used for both thin and thick concrete elements?

- Yes, steel formwork can be used for both thin and thick concrete elements. Steel formwork is versatile and can be easily adjusted or modified to accommodate different thicknesses of concrete. It provides strength and stability, making it suitable for various construction projects, such as walls, columns, beams, slabs, and even complex architectural structures. Steel formwork also offers a smooth and precise finish to the concrete, ensuring high-quality results. Additionally, steel formwork is durable and can be reused multiple times, making it a cost-effective choice for both thin and thick concrete elements.

- Q: Can steel formwork be used for curved or complex shapes?

- Yes, steel formwork can be used for curved or complex shapes. Steel is a flexible and durable material that can be easily shaped and molded to fit various designs. It offers the advantage of being able to create intricate and customized formwork systems that can be used for a wide range of applications, including curved or complex shapes. The strength and stability of steel also ensure that the formwork remains in place during the pouring and curing of concrete, allowing for precise and accurate construction. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for projects that require curved or complex shapes.

- Q: How does steel formwork prevent concrete mixture separation during pouring?

- In construction projects, steel formwork is employed to create a temporary structure that securely holds the concrete in position until it solidifies and becomes rigid. A significant advantage of utilizing steel formwork is its ability to prevent the concrete mixture from disintegrating while it is being poured. The steel formwork is meticulously designed and assembled to establish a tight enclosure for the concrete, guaranteeing that it maintains its intended shape and texture. It consists of firmly fastened steel panels and frames, which combine to form a sturdy structure. When the concrete mixture is poured into the steel formwork, it is effectively restrained by the formwork walls itself. The steel panels and frames offer a smooth and uniform surface onto which the concrete can be poured, effectively averting any separation or division within the mixture. Moreover, the steel formwork is purposefully constructed with accurately aligned joints and connections, which further prevents any leakage or permeation of the concrete mixture. This ensures the integrity of the concrete, preventing it from breaking down into its constituent materials such as aggregates, cement, and water. Additionally, the steel formwork possesses the capacity to withstand the pressure exerted by the weight of the concrete. This successfully averts any deformation or displacement of the formwork during the pouring process, as such movements could potentially lead to the separation or shifting of the concrete. All in all, the utilization of steel formwork provides a robust and steady structure that effectively prevents the concrete mixture from separating during pouring. It ensures the concrete maintains its desired form and consistency, ultimately resulting in a finished product that is of high quality and durability.

- Q: What are the common design considerations for steel formwork in marine environments?

- When designing steel formwork for marine environments, there are several common considerations that need to be taken into account. These considerations are necessary to ensure the durability and longevity of the formwork in the harsh marine environment. Some of the common design considerations for steel formwork in marine environments include: 1. Material Selection: The selection of appropriate materials is crucial for withstanding the corrosive effects of saltwater. Stainless steel or other corrosion-resistant alloys should be used to prevent rusting and deterioration. 2. Coatings and Surface Treatments: Applying protective coatings or surface treatments can further enhance the corrosion resistance of the steel formwork. These coatings may include zinc-rich primers, epoxy coatings, or galvanization to provide an additional layer of protection. 3. Reinforcement and Strengthening: Marine environments can subject the formwork to significant forces such as waves, currents, and impact from floating debris. Reinforcement and strengthening measures, such as additional bracing or thicker steel sections, may be necessary to ensure structural integrity. 4. Drainage and Ventilation: Proper drainage and ventilation are crucial to prevent the accumulation of water, which can accelerate corrosion. Designing the formwork with appropriate drainage channels or weep holes can help remove any trapped moisture. 5. Connection Details: Special attention should be given to the connection details in marine environments. Corrosion-resistant fasteners, such as stainless steel bolts or galvanized screws, should be used to prevent premature failure due to corrosion. 6. Maintenance and Inspection: Regular maintenance and inspection are essential to identify any signs of corrosion or damage. Scheduled cleaning, removal of marine growth, and applying protective coatings as needed will help extend the life of the formwork. 7. Environmental Considerations: The marine environment is often subject to extreme conditions such as high winds, tidal forces, and exposure to UV radiation. The design should consider these factors to ensure the formwork can withstand these environmental loads. Overall, the design of steel formwork for marine environments necessitates careful consideration of material selection, coatings, reinforcement, drainage, connection details, maintenance, and environmental factors. By incorporating these considerations into the design process, engineers can ensure that the formwork will withstand the harsh marine conditions and provide a reliable and durable solution.

- Q: How does steel formwork affect the overall safety of construction workers?

- Steel formwork can significantly enhance the overall safety of construction workers due to its robust and durable nature. Steel formwork provides a sturdy framework, ensuring stability and preventing collapses or accidents during concrete pouring and curing processes. Its strength and rigidity also minimize the risk of formwork failure, reducing the chances of injuries caused by falling debris or equipment. Additionally, steel formwork offers better fire resistance compared to other materials, further enhancing the safety of construction workers by reducing the potential for fire-related hazards.

- Q: What are the different types of finishes available for steel formwork panels?

- The different types of finishes available for steel formwork panels include galvanized, painted, and powder-coated finishes. Galvanized finishes provide corrosion resistance by applying a layer of zinc on the surface of the steel. Painted finishes add color and protection to the panels, while powder-coated finishes offer a durable and aesthetically pleasing coating that is resistant to chipping, scratching, and fading.

- Q: Can steel formwork be used for different types of concrete finishes?

- Yes, steel formwork can be used for different types of concrete finishes. Steel formwork is versatile and can be easily adjusted and customized to achieve different finishes, such as smooth, textured, or patterned surfaces. It provides a strong and rigid structure, allowing for precise shaping and detailing of the concrete. Additionally, steel formwork can be reused multiple times, making it cost-effective for various types of concrete finishes.

- Q: What are the typical environmental considerations when using steel formwork?

- Several typical environmental considerations need to be addressed when using steel formwork. Firstly, the production of steel requires a substantial amount of energy and natural resources, resulting in environmental degradation and greenhouse gas emissions. To address these impacts, it is crucial to prioritize the use of recycled or reclaimed steel whenever possible. This reduces the demand for new steel production and lessens the environmental footprint associated with the formwork. Another key consideration is the waste generated during construction. Steel formwork produces a significant amount of waste, including offcuts and discarded pieces. Proper waste management practices, such as recycling or reusing these materials, should be implemented to minimize the environmental impact. In addition, the transportation of steel formwork contributes to carbon emissions and air pollution. Optimizing transportation routes and modes, and choosing more sustainable options like rail or water, should be pursued whenever feasible. Furthermore, the use of steel formwork can impact the construction site itself. The installation and removal of the formwork can disturb the natural environment, leading to soil erosion and habitat destruction. Implementing erosion control measures and minimizing the formwork's footprint can help mitigate these impacts. Lastly, the longevity and durability of steel formwork should be considered. With proper maintenance and reuse, steel formwork can have a long lifespan, reducing the need for frequent replacement and ultimately minimizing waste and resource consumption. In conclusion, when using steel formwork, it is essential to consider the entire lifecycle of the material and adopt sustainable practices to minimize its environmental impact. This includes prioritizing recycled steel, implementing proper waste management, optimizing transportation, mitigating site disturbance, and promoting durability and reuse.

- Q: How does steel formwork handle different concrete reinforcement types?

- Steel formwork is an excellent choice for dealing with various types of concrete reinforcement due to its versatility and durability. It is commonly used in construction projects to create temporary molds or structures that hold concrete in place during the pouring and curing process. One of the benefits of steel formwork is its ability to handle different types of concrete reinforcement. Whether it's traditional reinforcement like steel bars or modern techniques such as fiber-reinforced polymers (FRP), steel formwork can accommodate them all. Steel formwork is specifically designed to be strong and rigid, enabling it to support the weight and pressure exerted by different reinforcement materials. It can withstand the forces exerted by steel bars or the tensile strength of FRP without experiencing any deformations or collapsing. Furthermore, steel formwork is highly adaptable and can be easily adjusted or modified to suit different reinforcement types. It can be cut or welded to create openings or recesses for steel bars or other materials to pass through. This flexibility guarantees that steel formwork can be tailored to meet the specific requirements of each construction project. Moreover, steel formwork provides a smooth and even surface finish, which is crucial for ensuring proper adhesion between the concrete and the reinforcement materials. This ensures that the reinforcement is securely embedded within the concrete structure, offering the necessary structural integrity and strength. To conclude, steel formwork is a dependable and efficient solution for managing different types of concrete reinforcement. Its strength, adaptability, and ability to provide a smooth surface finish make it an ideal choice for construction projects that necessitate diverse reinforcement materials.

- Q: How does steel formwork affect the overall waterproofing of a building?

- The main purpose of steel formwork is to provide stability and shape to wet concrete during the construction process. It does not directly affect the overall waterproofing of a building. Waterproofing is typically achieved through the use of waterproof membranes, sealants, or coatings applied to the external surfaces of the structure. Proper installation and sealing of the formwork joints are important to prevent water leakage during the concrete pouring process. Any gaps or cracks in the formwork can allow water to seep into the structure, potentially compromising the waterproofing system. Additionally, the choice of formwork material indirectly influences the overall waterproofing of a building. Steel formwork, being durable and robust, can withstand the pressure of wet concrete without deforming or leaking. This ensures that the concrete is shaped and compacted correctly, resulting in a more solid and stable structure. A well-constructed concrete framework indirectly contributes to the building's waterproofing capabilities by enhancing its integrity and longevity. In conclusion, while steel formwork does not directly impact the overall waterproofing of a building, it is crucial for maintaining the structural integrity of the concrete during construction. Proper installation and sealing of formwork joints are necessary to prevent water leakage. Ultimately, the choice and correct application of appropriate waterproofing materials determine the building's overall waterproofing performance.

Send your message to us

Stair tower for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords