Adjustable Arced Timber Beam Formwork for Circle Column

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

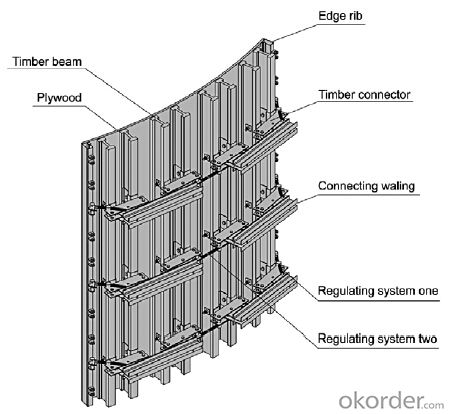

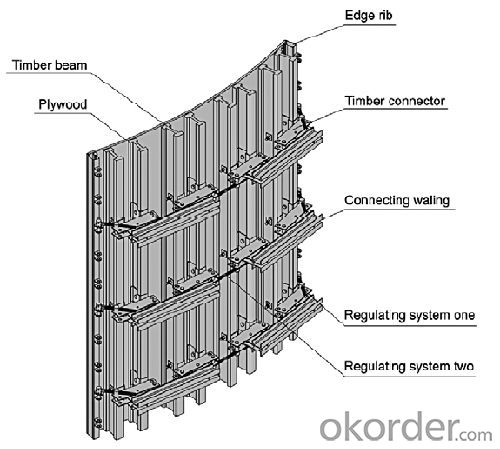

1. Structure of Curve Concrete Wall Formwork

TBW system-C is a kind of formwork for pouring curve wall, it is composed of several pieces of Tim-formwork, tie rod, wing nut, etc.

It will be designed according to wall’s size.

2. Main Features of Curve Concrete Wall Formwork

1. Quickly construction with TBW system-C.

2. Light weight but high bearing capacity. For conventional design, its load bearing capacity is 60KN/m2 with weight of 60-80kg/m2. If required, the formwork can be specially designed for higher concrete pressures.

3. Timber is easy re-sized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

3. Curve Concrete Wall Formwork Images

4. Curve Concrete Wall Formwork Specification

5. FAQ of Curve Concrete Wall Formwork

1) What can we do for you?

We can ensure the quality of the Curve Concrete Wall Formwork and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Curve Concrete Wall Formwork, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Curve Concrete Wall Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel formwork be used for both residential and commercial renovations?

- Yes, steel formwork can be used for both residential and commercial renovations. Steel formwork is a versatile and durable option that can withstand the demands of various construction projects, making it suitable for both residential and commercial renovations. Its strength and stability make it ideal for creating concrete structures in both types of buildings.

- Q: How does steel formwork affect the overall structural integrity of a building?

- Steel formwork plays a crucial role in ensuring the overall structural integrity of a building. It is a temporary mold or framework that is used during the construction process to shape and support concrete until it hardens and gains sufficient strength to bear its own weight and other applied loads. One of the key advantages of steel formwork is its superior strength and durability compared to other types of formwork such as wood or plastic. Steel is known for its high tensile strength and resistance to deformation, which allows it to withstand the pressure exerted by wet concrete without any significant distortion. This strength ensures that the formwork maintains its shape and stability during the pouring and curing of concrete, preventing any potential collapse or failure that could compromise the structural integrity of the building. Moreover, the use of steel formwork provides precise and accurate results in terms of dimension and shape, which is essential for achieving the desired structural integrity. Steel formwork can be fabricated to exact specifications, allowing for tight tolerances and accurate positioning of reinforcement, resulting in a more uniform and robust structure. This precision ensures that the building can withstand various external loads, such as wind, seismic forces, and live loads, without experiencing excessive deflection or deformation. Additionally, steel formwork offers excellent reusability, making it a cost-effective and sustainable option in construction projects. Unlike other types of formwork that may require frequent replacement, steel formwork can be used multiple times, reducing material waste and overall project costs. This reusability also contributes to the structural integrity of the building, as the formwork is less prone to deterioration or degradation over time, ensuring consistent quality and performance. In summary, steel formwork significantly enhances the overall structural integrity of a building by providing superior strength, precision, and durability. Its ability to withstand the pressure of wet concrete, maintain accurate dimensions, and resist external loads ensures the structural stability and safety of the building. Moreover, the reusability of steel formwork offers cost-effective and sustainable advantages, further contributing to the long-term structural integrity of the constructed building.

- Q: How does steel formwork prevent concrete leakage?

- Steel formwork prevents concrete leakage by providing a strong and rigid structure that holds the concrete in place during the pouring and curing process. The steel panels are tightly connected and sealed to form a watertight barrier, preventing any leakage or seepage of the concrete.

- Q: Is steel formwork resistant to fire?

- Yes, steel formwork is generally resistant to fire. Steel itself has a high melting point and does not easily ignite or contribute to the spread of fire. In the case of steel formwork, it is typically designed and manufactured to withstand high temperatures without deformation or structural failure. This makes it a suitable choice for construction projects that require fire-resistant materials. Additionally, steel formwork can also provide better fire protection for the concrete being poured into it, as concrete has inherent fire-resistant properties. However, it is important to note that the fire resistance of steel formwork can also depend on factors such as the thickness of the steel, the design of the formwork, and the fire protection measures in place at the construction site. It is always advisable to consult with professionals and follow appropriate fire safety regulations and guidelines when using steel formwork in construction projects.

- Q: Are there any specific safety measures to be followed during steel formwork installation?

- Yes, there are specific safety measures that should be followed during steel formwork installation. Here are some of the most important ones: 1. Personal Protective Equipment (PPE): All workers involved in the installation of steel formwork should wear appropriate PPE, including safety helmets, gloves, safety glasses, and steel-toed boots. This will help protect against potential head injuries, hand injuries, eye injuries, and foot injuries. 2. Training and Competency: Workers should be properly trained and competent in the installation of steel formwork. They should have a good understanding of the equipment being used, the proper installation techniques, and the potential hazards associated with the work. 3. Equipment Inspection: Before starting the installation process, all formwork equipment, including steel frames, braces, and connectors, should be inspected for any damage or defects. Any damaged or defective equipment should be taken out of service and replaced. 4. Secure and Stable Platform: A secure and stable platform should be established for workers to safely install the steel formwork. This may involve the use of scaffolding or other supporting structures. The platform should be properly erected and inspected for stability before work begins. 5. Fall Protection: Fall protection measures should be in place to prevent workers from falling while installing the steel formwork. This may include the use of guardrails, safety harnesses, and safety nets. Workers should be properly trained in the use of fall protection equipment and procedures. 6. Lifting and Handling: Proper lifting and handling techniques should be used when moving and positioning steel formwork. Workers should avoid overexertion and use mechanical aids, such as cranes or hoists, when necessary. Additionally, workers should be mindful of their posture and avoid awkward or strenuous lifting positions. 7. Communication and Coordination: Effective communication and coordination among workers is crucial during steel formwork installation. This includes clear instructions, proper signaling, and a designated person in charge of coordinating the work. This will help prevent accidents and ensure a smooth and safe installation process. By following these safety measures, the risk of accidents and injuries during steel formwork installation can be significantly reduced, creating a safer working environment for all involved.

- Q: Steel formwork in the construction project, after the completion of concrete pouring, the wall surface from the powder seriously how to deal with?

- There is a problem with the ratio of the concrete itself.

- Q: Can steel formwork be used for hospital construction projects?

- Yes, steel formwork can be used for hospital construction projects. Steel formwork is a versatile and durable construction material that offers several advantages for hospital projects. It provides excellent strength and stability, which is crucial for ensuring the safety and integrity of the building. Steel formwork also allows for efficient and precise construction, as it can be easily assembled and disassembled, and its modular nature allows for flexibility in design and layout changes. Additionally, steel formwork has a smooth surface finish, which is important for maintaining a hygienic environment in a hospital setting. It is also resistant to moisture and chemicals, making it suitable for areas that require frequent cleaning and sterilization. Overall, steel formwork is a reliable and suitable choice for hospital construction projects.

- Q: How does steel formwork affect the overall speed of construction?

- Steel formwork can greatly increase the overall speed of construction due to its numerous advantages. Firstly, steel formwork is highly durable and can withstand the pressure of concrete pouring without any deformation or damage. This durability enables multiple reuses of the formwork, eliminating the need to constantly replace it with new materials, thus saving time and cost. Moreover, steel formwork provides a smooth and even surface finish, which reduces the time required for further plastering or finishing work. This smooth finish also ensures accurate and precise alignment of structural elements, resulting in faster and more efficient construction. Additionally, steel formwork is easy to assemble and disassemble, allowing for quick installation and removal. This ease of use eliminates the need for extensive labor and minimizes the time required for the formwork setup, ultimately accelerating the construction process. Furthermore, steel formwork is highly adaptable and can be used for various types of building structures. Its flexibility allows for customization and efficient utilization in different construction projects, increasing the overall speed of construction. In conclusion, the use of steel formwork positively impacts the overall speed of construction by providing durability, smooth finish, easy assembly and disassembly, and adaptability. These advantages result in time and cost savings, efficient construction processes, and ultimately faster project completion.

- Q: How does steel formwork affect the overall constructability of a structure?

- Steel formwork can greatly improve the constructability of a structure due to its durability, strength, and versatility. It allows for faster and more efficient construction processes, as it can be easily fabricated and reused multiple times. The rigidity of steel formwork ensures accurate and precise concrete placement, resulting in a higher quality finish. Additionally, the use of steel formwork allows for larger spans and heights, reducing the need for additional supports and enhancing the overall structural integrity of the building.

- Q: How does steel formwork handle different concrete water-cement ratio specifications?

- Due to its inherent strength and durability, steel formwork is widely favored for managing various concrete water-cement ratio specifications. Its robust design enables it to withstand the pressure exerted by wet concrete during pouring and curing, regardless of the water-cement ratio. The water-cement ratio in concrete refers to the proportion of water used in relation to the amount of cement. It plays a pivotal role in determining the concrete's strength, workability, and durability. Different water-cement ratio specifications are often necessary for different construction projects, depending on factors such as the desired concrete strength and environmental conditions. Steel formwork offers a strong and rigid framework that effectively contains different concrete mixtures, irrespective of the water-cement ratio. The steel panels and frames are specifically engineered to securely hold the wet concrete, preventing any leakage or deformation during casting and curing. This guarantees that the concrete retains its desired shape and strength. Furthermore, the reusability of steel formwork is advantageous, particularly when dealing with varying water-cement ratio specifications. Once the concrete has set and cured, the steel formwork can be easily disassembled, cleaned, and reassembled for future use. This not only saves time and money but also provides flexibility in adapting to different water-cement ratio requirements. Additionally, steel formwork systems can be easily adjusted and customized to accommodate specific project needs. This includes modifying the formwork to achieve the desired concrete surface finish and shape. The versatility of steel formwork enables contractors to work with different water-cement ratio specifications without compromising the quality and integrity of the final concrete structure. In conclusion, steel formwork is an excellent option for managing various concrete water-cement ratio specifications. Its strength, durability, and adaptability make it a reliable solution for containing wet concrete and ensuring the maintenance of the desired water-cement ratio throughout the construction process.

Send your message to us

Adjustable Arced Timber Beam Formwork for Circle Column

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords