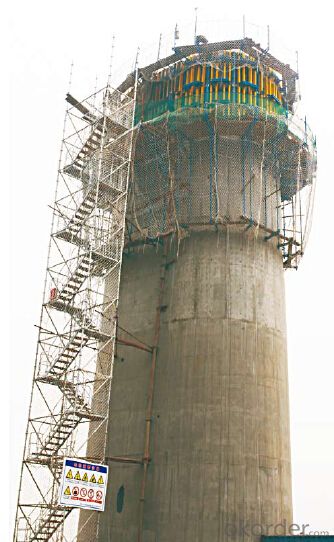

Stair tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: How does steel formwork affect the structural integrity of a building?

- Steel formwork is a construction technique that uses steel molds to create the desired shape and structure of concrete elements in a building. It plays a crucial role in the construction process and affects the structural integrity of a building in several ways. Firstly, steel formwork provides a strong and rigid support system for the wet concrete during the pouring and setting process. Its robustness ensures that the concrete remains in the desired shape and prevents any deformation or collapse. This is particularly important for structural elements such as beams, columns, and walls, as it ensures their proper alignment and stability. Additionally, steel formwork allows for precise and accurate construction. The molds can be fabricated with great precision, resulting in accurate dimensions and shapes for the concrete elements. This precision is essential for maintaining the structural integrity of the building, as any slight deviation or misalignment can compromise the overall strength and stability of the structure. Moreover, steel formwork provides a smooth surface finish to the concrete. This smoothness is not only aesthetically pleasing but also contributes to the structural integrity of the building. A smooth surface reduces the likelihood of cracks, voids, or air pockets in the concrete, which can weaken its strength and durability. Furthermore, steel formwork offers durability and reusability. Unlike other types of formwork, such as wood or plastic, steel formwork can withstand multiple uses without losing its structural integrity. This reusability not only saves construction costs but also ensures consistency in the quality of the concrete elements throughout the building. Lastly, steel formwork enhances the overall structural stability of the building. The use of steel molds provides a rigid framework that distributes the loads evenly and efficiently. This distribution of loads minimizes the risk of localized stress concentrations, thereby improving the structural integrity of the building and increasing its overall resistance to external forces such as wind, earthquakes, or heavy loads. In conclusion, steel formwork significantly impacts the structural integrity of a building in a positive way. It provides a strong support system, ensures precision and accuracy, offers a smooth surface finish, provides durability and reusability, and enhances overall structural stability. All these factors contribute to the strength, stability, and longevity of the building, making steel formwork an essential component in modern construction practices.

- Q: What are the different types of formwork release agents used with steel formwork?

- There are primarily two types of formwork release agents used with steel formwork: barrier release agents and reactive release agents. Barrier release agents create a physical barrier between the steel formwork and the concrete, preventing adhesion. Reactive release agents, on the other hand, chemically react with the concrete to create a thin film that facilitates easy stripping of the formwork. Both types of release agents are commonly used in construction projects to ensure the smooth and efficient removal of steel formwork.

- Q: Those who have these drawings, can send a copy to me, online, etc.

- As long as the designer noted that the length of the beam, and the design of the whole number of expansion joints, there is a good design of the template.

- Q: How does steel formwork affect the overall project cost estimation?

- Steel formwork can have a significant impact on the overall project cost estimation. While it may have a higher upfront cost compared to traditional materials like wood or plywood, steel formwork offers several advantages that can help offset these initial expenses. Its durability and reusability make it a cost-effective choice in the long run as it eliminates the need for frequent replacements or repairs. Additionally, steel formwork enables faster construction times due to its strength and stability, reducing labor costs and potentially accelerating project timelines. Therefore, although steel formwork may contribute to higher upfront costs, it can ultimately lead to cost savings and efficiency improvements, positively impacting the overall project cost estimation.

- Q: Are there any limitations to using steel formwork?

- There are indeed limitations to the use of steel formwork. Initially, steel formwork proves to be relatively costly in comparison to alternative materials such as wood or plastic. Consequently, this can result in it being less cost-effective for smaller or budget-constrained projects. Furthermore, the weight of steel formwork necessitates the use of heavy lifting equipment during installation and removal. This presents a challenge in areas with restricted access or where cranes and other heavy machinery may not be readily accessible. Moreover, skilled labor is required for the proper installation and dismantling of steel formwork. It is imperative to employ experienced workers who possess familiarity with the utilization of steel formwork to ensure the system's safety and effectiveness. In addition, if not adequately protected, steel formwork is prone to corrosion. This can be a cause for concern in environments with high humidity or exposure to moisture, thereby necessitating additional maintenance and protective measures. Lastly, steel formwork lacks the flexibility and adaptability of other formwork materials. It may not be suitable for intricate or irregular shapes, and may require more time and effort to customize according to specific project requirements. In conclusion, although steel formwork offers durability and strength, its limitations in terms of cost, weight, labor requirements, susceptibility to corrosion, and flexibility should be taken into consideration when selecting the most suitable formwork system for a particular construction project.

- Q: What are the common quality control measures for steel formwork?

- Some common quality control measures for steel formwork include regular inspections to check for any defects or damage, ensuring proper installation and alignment of the formwork, monitoring the strength and stability of the structure, conducting load tests to assess the capacity of the formwork, and verifying compliance with relevant industry standards and specifications. Additionally, proper storage and maintenance of the steel formwork are essential to prevent corrosion and prolong its lifespan.

- Q: Can steel formwork be used for retaining walls?

- Retaining walls can indeed utilize steel formwork. The popularity of steel formwork for retaining walls stems from its robustness and resilience. It effectively bolsters and stabilizes the concrete throughout the construction phase. The steel formwork's ability to withstand the immense pressure exerted by both the concrete and the soil behind the retaining wall guarantees the structural integrity of the wall. Moreover, the versatility of steel formwork enables the creation of diverse retaining wall designs, as it can adapt to different shapes and sizes. Ultimately, steel formwork proves to be a dependable and efficient choice for retaining walls, ensuring durability and ease of construction.

- Q: What are the different types of formwork bracing used with steel formwork?

- There are several types of formwork bracing commonly used with steel formwork, including diagonal bracing, kickers, horizontal bracing, and cross bracing. These bracing systems are used to provide stability and resist lateral forces during the construction process.

- Q: Can steel formwork be used in tunnel construction?

- Yes, steel formwork can be used in tunnel construction. Steel formwork is widely used in construction projects, including tunnel construction, due to its durability, strength, and versatility. It provides a rigid support structure that can withstand the pressure and stress exerted by the surrounding soil and rock in tunneling operations. Steel formwork is designed to be easily assembled and disassembled, allowing for efficient tunnel construction. It can be customized to fit the specific shape and dimensions of the tunnel, ensuring accurate and precise formwork. Additionally, steel formwork can be reused multiple times, making it a cost-effective solution for tunnel construction projects.

- Q: How does steel formwork affect the overall productivity of the construction process?

- Steel formwork can significantly enhance the overall productivity of the construction process. Due to its durability and strength, steel formwork allows for faster assembly and disassembly, reducing the time required for each construction cycle. Its reusable nature also reduces the need for constant replacements, reducing both material and labor costs. Additionally, the precise and consistent dimensions of steel formwork ensure accurate and high-quality construction, minimizing errors and rework. Overall, steel formwork increases efficiency, reduces construction time, and enhances the productivity of the construction process.

Send your message to us

Stair tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords