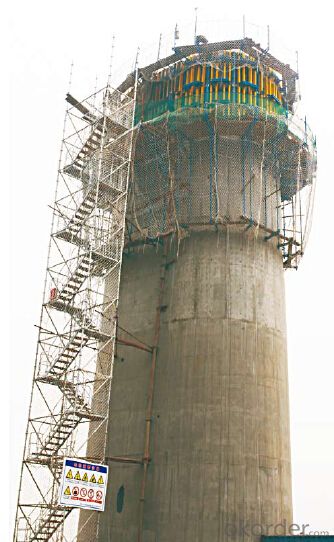

Stair tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used in areas with extreme temperature variations?

- Yes, steel formwork can be used in areas with extreme temperature variations. Steel is known for its durability and strength, which allows it to withstand various temperature conditions. However, it is important to consider potential expansion and contraction of the steel due to temperature changes, and take appropriate measures to prevent any negative effects on the formwork structure.

- Q: What are the considerations for designing steel formwork systems?

- When designing steel formwork systems, there are several important considerations that need to be taken into account. These considerations include: 1. Load-bearing capacity: Steel formwork systems must be designed to withstand the loads imposed by the concrete during pouring and curing. This includes the weight of the concrete, as well as any additional loads such as equipment or workers. 2. Safety: The safety of workers is of utmost importance when designing steel formwork systems. The system should be designed to provide a stable and secure working platform, with proper guardrails, access points, and fall protection measures. 3. Durability: Steel formwork systems should be designed to withstand the harsh conditions of construction sites, including exposure to weather elements, chemicals, and repeated use. The materials used should be corrosion-resistant and able to maintain their structural integrity over time. 4. Flexibility and adaptability: The design of the steel formwork system should allow for easy assembly, disassembly, and reusability. It should be adaptable to different project requirements and able to accommodate changes in design or construction methods. 5. Cost-effectiveness: The overall cost of the steel formwork system, including its initial investment, maintenance, and lifespan, should be considered. Designing a system that balances cost with performance and durability is essential. 6. Construction schedule: The design of the steel formwork system should take into account the construction schedule and the time required for assembly, concrete pouring, and formwork removal. The system should be designed to minimize downtime and facilitate efficient construction processes. 7. Environmental impact: Consideration should be given to the environmental impact of the steel formwork system, such as the use of sustainable materials, recycling options, and minimizing waste generation. Overall, designing steel formwork systems requires a comprehensive approach that takes into account structural integrity, safety, durability, flexibility, cost-effectiveness, construction schedule, and environmental factors. By considering these considerations, a well-designed steel formwork system can greatly contribute to the success of a construction project.

- Q: How does steel formwork contribute to the construction process?

- Steel formwork contributes to the construction process by providing a durable and reusable framework for concrete pouring. It ensures accurate shaping and alignment of the structure, allowing for efficient construction and reduced labor costs. Additionally, steel formwork offers increased strength and stability, enabling the creation of complex and high-rise structures with precision.

- Q: What is the maintenance required for steel formwork?

- To maintain steel formwork, cleaning and storage are of utmost importance. After each use, it is crucial to thoroughly clean the formwork to eliminate any concrete residue or debris. This can be accomplished by employing water and a brush or pressure washer. Additionally, any signs of rust should be addressed with a rust converter and a coat of paint to prevent further deterioration. Proper storage plays a vital role in maintaining steel formwork. It should be kept in a dry and well-ventilated area to prevent the accumulation of moisture and subsequent rusting. If feasible, storing the formwork above ground level will minimize contact with moisture. To ensure the formwork remains in optimal working condition, regular inspections should be conducted to detect any damages or signs of wear and tear. Any bent or damaged components should be promptly repaired or replaced. In summary, maintaining steel formwork entails regular cleaning, appropriate storage, and thorough inspections to guarantee its longevity and effectiveness in construction projects.

- Q: What are the different types of corner solutions available for steel formwork?

- Steel formwork offers various types of corner solutions, each with its own advantages and applications. 1. For external corners in concrete structures, L-shaped or angled brackets are commonly used. These brackets are easy to install and provide a clean and sharp finish. They find frequent use in building construction, particularly for walls and columns. 2. Internal corners in concrete structures can also be formed using L-shaped or U-shaped brackets. Similar to external corner solutions, they are widely used in the construction of walls, slabs, and beams. 3. Adjustable corner solutions are highly versatile, allowing for adjustable angles and dimensions. They are designed to accommodate complex structures or irregular shapes. These solutions are often employed for curved walls, circular columns, and other unique architectural features. 4. Hinged corner solutions are specialized brackets that facilitate easy removal of formwork once the concrete has cured. With hinges, the formwork can be opened and closed, providing quick and efficient access to the concrete surface. Hinged corner solutions are commonly used in applications where frequent access to the concrete surface is necessary, such as tunnels or underground structures. 5. Reinforced corner solutions are specifically designed to provide additional strength and support to the corners of concrete structures. They incorporate steel bars or plates to enhance structural integrity and durability. Reinforced corner solutions are frequently utilized in high-rise buildings, bridges, and other heavy-duty structures. Ultimately, the choice of corner solution depends on the specific requirements of the construction project, including the desired finish, structural integrity, and ease of installation and removal. It is crucial to consider these factors and consult with a structural engineer or formwork specialist to determine the most suitable corner solution for a particular application.

- Q: What are the fire resistance properties of steel formwork?

- Steel formwork has excellent fire resistance properties due to its high melting point and low thermal conductivity. It is able to withstand high temperatures for extended periods of time without losing its structural integrity, making it a safe and reliable choice for construction projects in fire-prone areas.

- Q: Can steel formwork be used for foundation walls?

- Yes, steel formwork can be used for foundation walls. Steel formwork is a durable and strong material that provides excellent support for concrete during the construction process. It can be used for both horizontal and vertical applications, including foundation walls. Steel formwork offers several advantages such as high load-bearing capacity, reusable nature, and ease of installation and removal. It allows for precise shaping of foundation walls and ensures a smooth and uniform finish. Additionally, steel formwork is resistant to moisture and can withstand harsh weather conditions, making it suitable for foundation walls in various environments.

- Q: Can steel formwork be used for precast concrete facades?

- Yes, steel formwork can be used for precast concrete facades. Steel formwork provides a strong and durable framework for casting precast concrete panels and is commonly used in the construction industry for various applications, including facades. It offers the advantage of being reusable, allowing for cost savings and faster construction times. Additionally, steel formwork can be easily customized to create intricate designs and complex shapes, making it a suitable choice for precast concrete facades.

- Q: Can steel formwork be customized to specific project requirements?

- Yes, steel formwork can be customized to specific project requirements. Steel formwork is highly versatile and can be easily modified or adjusted to meet the unique needs of different construction projects. It can be designed and fabricated in various sizes, shapes, and configurations to accommodate specific project requirements, such as complex geometries, special structural elements, or specific finishing requirements. Additionally, steel formwork can be reused multiple times, further enhancing its adaptability and customization potential.

- Q: Can steel formwork be used in tunnel construction projects?

- Certainly! Tunnel construction projects can indeed utilize steel formwork. When it comes to tunnel construction, steel formwork is widely preferred because of its durability, strength, and ability to be reused. This type of formwork offers a strong and reliable framework for pouring concrete, aiding in achieving precise and accurate dimensions in tunnel construction. Moreover, steel formwork is capable of withstanding the pressures exerted by the surrounding soil and the weight of the concrete, which guarantees the stability and safety of the tunnel structure. In addition to these advantages, steel formwork is resistant to corrosion and boasts a longer lifespan compared to other formwork options, making it an excellent choice for tunnel construction projects that require longevity.

Send your message to us

Stair tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords