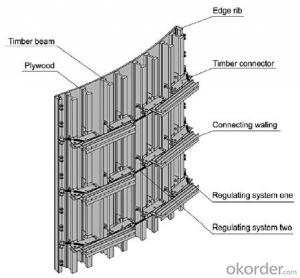

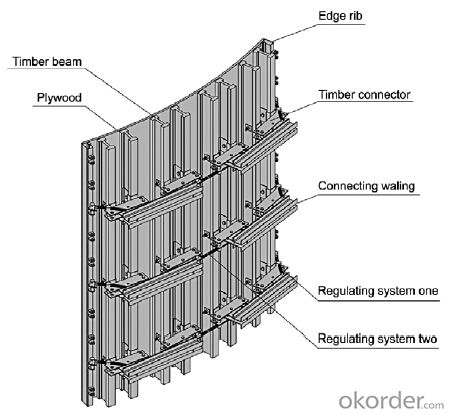

Adjustable Arced Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: Can steel formwork be used for airport construction projects?

- Yes, steel formwork can be used for airport construction projects. Steel formwork is a versatile and durable option for constructing various concrete structures, including those found in airports. It offers several advantages such as high strength, stability, and reusability, making it suitable for large-scale projects like airport construction. Steel formwork can withstand the heavy loads and pressures associated with airport infrastructure, allowing for the construction of runways, taxiways, aprons, and other structures. Additionally, its modular design and flexibility enable easy customization and adaptation to different project requirements. Overall, steel formwork is a reliable choice for airport construction projects due to its strength, durability, and adaptability.

- Q: What are the typical safety precautions when working with steel formwork?

- When working with steel formwork, some typical safety precautions include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential hazards. Additionally, workers should receive proper training on the proper handling and installation techniques of steel formwork systems. It is essential to ensure that the formwork is securely supported and adequately braced to prevent collapse or accidents. Regular inspection of the formwork for any damages or defects is also crucial to maintain a safe working environment.

- Q: Can steel formwork be used in marine construction projects?

- Yes, steel formwork can be used in marine construction projects. Steel formwork is a durable and versatile construction material that can withstand the harsh conditions of marine environments such as saltwater, waves, and corrosion. It is often used in marine construction projects for various applications such as building piers, docks, seawalls, and other structures that require a strong and stable foundation. Steel formwork provides excellent structural support and can withstand the heavy loads and pressures associated with marine construction. Additionally, steel formwork can be easily assembled and disassembled, making it a practical choice for marine construction projects where time and efficiency are crucial. Overall, steel formwork is a reliable and suitable option for marine construction projects.

- Q: How does steel formwork affect the overall construction site logistics?

- The overall construction site logistics can be significantly impacted by steel formwork. Firstly, the durability and strength of steel formwork allow for multiple reuses, reducing the need for constant replacement and disposal of materials. This results in reduced waste generation and improved site cleanliness. Moreover, steel formwork is lightweight and easily adjustable, making it easier to handle and transport around the construction site. This improves material handling efficiency and reduces the time required for installation and removal of formwork. Additionally, the lightweight nature of steel formwork reduces the load on the structure, leading to reduced transportation costs and improved safety during construction. Furthermore, steel formwork offers high dimensional accuracy, ensuring precise and consistent shapes for concrete elements. This helps streamline the construction process by reducing the need for excessive adjustments and rework, resulting in improved time management and increased productivity. Additionally, steel formwork provides a smooth and even finish to concrete structures, eliminating the need for additional surface treatments and reducing the time and effort required for finishing work. In summary, steel formwork contributes to improved construction site logistics by reducing waste, enhancing material handling efficiency, improving construction speed, and ensuring high-quality finishes. Its durability, lightweight nature, and dimensional accuracy make it a valuable asset in optimizing construction processes and achieving project timelines more effectively.

- Q: Is steel formwork easy to assemble and disassemble?

- Yes, steel formwork is relatively easy to assemble and disassemble compared to other types of formwork systems. Steel formwork consists of prefabricated panels that can be easily connected and secured together using various methods such as clamps, pins, or wedges. The panels are typically lightweight and come in standardized sizes, making them easy to handle and transport. Moreover, steel formwork offers the advantage of being adjustable and reusable. The panels can be easily adjusted to different dimensions and shapes by using adjustable screws or other mechanisms, allowing for flexibility in construction projects. Additionally, steel formwork can be used multiple times, significantly reducing the cost and time needed for formwork installation on subsequent projects. The disassembly process of steel formwork is also relatively simple. Once the concrete has cured, the panels can be easily removed by releasing the connecting mechanisms and dismantling the formwork system. The lightweight nature of steel formwork panels makes the handling and removal process easier and less labor-intensive compared to heavier formwork materials such as timber or plywood. Overall, the ease of assembly and disassembly of steel formwork makes it a preferred choice for many construction projects, especially those requiring repetitive use and quick turnaround times.

- Q: What are the different types of coatings applied to steel formwork panels?

- Steel formwork panels can be coated with various types of coatings to improve their durability and performance. Some commonly used coatings are: 1. Galvanized Coating: This coating is popular due to its excellent corrosion resistance. Steel panels are submerged in molten zinc, creating a protective layer. Galvanized coatings are long-lasting and can withstand harsh weather conditions. 2. Epoxy Coating: Epoxy coatings are commonly used to protect steel formwork panels from corrosion and chemical damage. These coatings are applied in two parts, with a primer applied first and then a topcoat. Epoxy coatings offer high resistance to chemicals, abrasion, and impact. 3. Powder Coating: In this dry finishing process, a dry powder is electrostatically applied to the steel formwork panels. The coated panels are then heated, melting the powder and creating a durable finish. Powder coatings provide excellent resistance to impact, chemicals, and UV rays. 4. Paint Coating: Paint coatings are frequently used to enhance the visual appeal of steel formwork panels. These coatings are typically applied in multiple layers, including a primer, intermediate coat, and topcoat. Paint coatings can provide some corrosion protection, but may require regular maintenance. 5. Concrete Release Coating: This coating is specifically designed to prevent concrete from sticking to the steel formwork panels. It creates a smooth, non-stick surface that allows for easy removal of cured concrete. Concrete release coatings are usually based on silicone or wax compounds. Choosing the right coating for steel formwork panels depends on project requirements, such as desired corrosion resistance, aesthetics, and durability. Consulting with a coatings expert or steel manufacturer can help in selecting the most suitable coating for the intended application.

- Q: How does steel formwork compare to aluminum formwork in terms of performance?

- Steel formwork and aluminum formwork are two commonly used materials in the construction industry for creating temporary molds or structures that hold concrete in place until it hardens. While both materials have their advantages and disadvantages, it is important to consider their performance aspects when comparing them. In terms of performance, steel formwork is known for its strength and durability. It has a high load-bearing capacity, making it suitable for heavy-duty applications. Steel formwork can withstand extreme weather conditions, rough handling, and repetitive use without significant wear and tear. The rigidity of steel formwork ensures that the structure maintains its shape during the concrete pouring process, resulting in accurate and precise finishes. Additionally, steel formwork allows for easy customization and modification to meet specific project requirements. On the other hand, aluminum formwork is preferred for its lightweight nature, which makes it easy to handle, transport, and assemble. The lightweight nature of aluminum formwork reduces labor costs and speeds up construction time. It also boasts excellent corrosion resistance, making it suitable for projects near coastal areas or in humid environments. Furthermore, aluminum formwork provides a smooth surface finish on the concrete, requiring minimal or no surface treatment. While both steel and aluminum formwork have their own advantages, the choice between the two depends on the specific requirements of the project. If the project involves heavy loads or requires a high number of reuses, steel formwork should be considered due to its superior strength and durability. However, if the project demands quick assembly, easy handling, and a smooth surface finish, aluminum formwork would be a better choice. Ultimately, the selection of steel or aluminum formwork should be based on a careful evaluation of the project's needs, budget, and timeline. A thorough assessment of the performance aspects, as well as other factors such as cost, maintenance, and environmental impact, will help determine the most suitable formwork material for a particular construction project.

- Q: What are the considerations when designing steel formwork for water tanks?

- When designing steel formwork for water tanks, there are several important considerations that need to be taken into account. These considerations include structural integrity, corrosion resistance, water tightness, and ease of construction. Firstly, structural integrity is crucial when designing steel formwork for water tanks. The formwork needs to be able to withstand the weight of the water and any additional loads such as surcharge or seismic forces. It is important to calculate the required thickness and reinforcement of the steel plates to ensure that they can safely support the weight of the water and prevent any structural failure. Secondly, corrosion resistance is another key consideration. Water tanks are constantly exposed to moisture, which can lead to the formation of rust and corrosion on the steel formwork. To mitigate this, it is important to use corrosion-resistant steel or apply protective coatings to the formwork. These coatings should be able to withstand the constant exposure to water and prevent any degradation of the steel. Water tightness is another crucial consideration when designing steel formwork for water tanks. The formwork needs to be able to retain the water without any leakage. This requires careful design and construction techniques such as proper sealing joints, welding, and the use of waterproofing materials. It is essential to ensure that there are no gaps or weak points in the formwork that could lead to water leakage. Lastly, ease of construction is an important consideration when designing steel formwork for water tanks. The formwork should be designed in such a way that it can be easily assembled and disassembled, allowing for efficient construction and maintenance. It is important to consider factors such as modular construction, ease of access for workers, and the use of appropriate lifting equipment. In conclusion, when designing steel formwork for water tanks, it is important to consider factors such as structural integrity, corrosion resistance, water tightness, and ease of construction. By carefully considering these factors, one can ensure the durability, functionality, and longevity of the water tank.

- Q: How does steel formwork contribute to better site organization?

- Steel formwork contributes to better site organization in several ways. Firstly, steel formwork is highly durable and reusable, which means it can be used multiple times on different construction projects. This eliminates the need for frequent replacement and reduces waste on site. The ability to reuse steel formwork also reduces storage space requirements, as it can be easily stacked and stored when not in use. Secondly, steel formwork is adjustable and customizable, allowing it to be easily modified to fit different shapes and sizes of concrete structures. This flexibility enables efficient use of space on site, as the formwork can be tailored to the specific requirements of each project. This ensures that the construction process is organized and streamlined, minimizing the need for additional materials or adjustments. Furthermore, steel formwork is known for its high strength and stability, which enhances site safety. Its robust structure provides a secure platform for workers to carry out their tasks, reducing the risk of accidents or injuries. This promotes a safer working environment and improves overall site organization. Steel formwork also contributes to better site organization by facilitating faster construction cycles. Its quick assembly and disassembly process allows for efficient and smooth workflow, enabling construction projects to be completed in a timely manner. This helps to minimize delays and ensures that the site is well-organized and productive. Lastly, steel formwork can be easily integrated with other construction systems and technologies. This compatibility allows for seamless coordination between different components of the project, promoting better site organization. Whether it is integrating with scaffolding systems or connecting to other structural elements, steel formwork ensures a cohesive and well-organized construction site. In conclusion, steel formwork contributes to better site organization through its durability, adjustability, strength, and compatibility with other construction systems. Its ability to be reused, customized, and integrated with other components enhances efficiency, safety, and productivity on construction sites.

- Q: What are the different types of steel used for formwork construction?

- There are several different types of steel that are commonly used for formwork construction. These include: 1. Mild Steel: This is the most commonly used type of steel for formwork construction. It is relatively inexpensive and has good strength and durability. Mild steel is suitable for most formwork applications and can withstand the pressure exerted by concrete during pouring. 2. High-strength Steel: As the name suggests, high-strength steel has greater strength and toughness than mild steel. It is often used in formwork construction where there is a need for higher load-bearing capacity or where the structure requires additional reinforcement. High-strength steel is more expensive than mild steel but provides greater structural integrity. 3. Structural Steel: This type of steel is commonly used in formwork construction for larger and more complex structures. It has high tensile strength and is capable of withstanding heavy loads. Structural steel is often used for formwork systems that require long spans, such as bridge construction or high-rise buildings. 4. Reinforcing Steel: Reinforcing steel, also known as rebar, is used in formwork construction to provide additional strength and reinforcement to the concrete structure. It is typically made of mild steel or high-strength steel and is placed within the formwork before pouring the concrete. Reinforcing steel helps to prevent cracking and improves the overall structural integrity of the formwork. 5. Stainless Steel: In certain cases, stainless steel may be used for formwork construction, especially in environments where corrosion resistance is required. Stainless steel has excellent resistance to rust and corrosion, making it suitable for use in marine or coastal construction projects. However, stainless steel is more expensive than other types of steel and may not be necessary for all formwork applications. In conclusion, the different types of steel used for formwork construction include mild steel, high-strength steel, structural steel, reinforcing steel, and stainless steel. The choice of steel will depend on factors such as load-bearing capacity, structural requirements, and environmental conditions.

Send your message to us

Adjustable Arced Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords