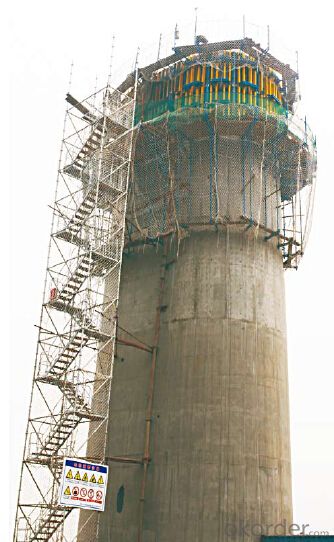

Stair Tower for Formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: How does steel formwork affect the overall thermal insulation of a structure?

- The thermal insulation of a structure is not directly influenced by steel formwork, as its primary function is to shape and support concrete during construction. Steel formwork is primarily used for providing structural stability and shaping concrete elements like walls, slabs, and columns. Other factors, such as the type and thickness of insulation materials, the design of the building envelope, and the presence of thermal bridges, primarily determine the overall thermal insulation of a structure. Insulation materials like foam boards, fiberglass, or mineral wool are typically installed within walls, floors, and roofs to limit heat transfer through conduction, convection, and radiation. Although steel formwork itself does not significantly contribute to thermal insulation, it can indirectly impact the insulation of a structure through its influence on the construction process. For example, if the steel formwork is not properly sealed or installed, it can create gaps or voids in the concrete, allowing heat to escape or enter the building. Moreover, inaccurate alignment of the formwork can affect the placement of insulation materials, leading to thermal bridging and reduced overall insulation effectiveness. Regardless of the formwork type used, it is crucial to implement proper insulation measures during the construction process. This involves ensuring correct installation of insulation materials without any gaps or thermal bridges, as well as proper sealing of the formwork to prevent air leakage. By addressing these aspects, the thermal insulation of the structure can be effectively maintained, irrespective of the presence of steel formwork.

- Q: How does steel formwork impact the overall energy efficiency of a structure?

- Steel formwork can have a significant impact on the overall energy efficiency of a structure. Firstly, steel formwork is highly durable and can be used repeatedly, reducing the need for new formwork materials for each construction project. This reduces the energy consumption associated with manufacturing and transporting formwork materials. Furthermore, steel formwork is known for its excellent thermal conductivity, which allows for efficient heat transfer. This property is particularly important in structures where energy efficiency is a priority, such as residential or commercial buildings. Efficient heat transfer can help maintain a comfortable indoor temperature, reducing the need for excessive heating or cooling, and thus minimizing energy consumption. In addition, steel formwork can contribute to the overall insulation of a structure. By using insulating materials in combination with steel formwork, a building's thermal performance can be significantly improved. This insulation helps to prevent heat loss during colder months and heat gain during warmer months, reducing the reliance on artificial heating and cooling systems. Consequently, energy consumption is reduced, leading to improved energy efficiency. Moreover, steel formwork can be designed to incorporate features that enhance natural lighting and ventilation in a structure. By allowing more natural light to enter the building, the need for artificial lighting during daylight hours is reduced, resulting in lower energy consumption. Similarly, by promoting natural ventilation, steel formwork can reduce the need for mechanical ventilation systems, further contributing to energy efficiency. Lastly, steel formwork's strength and stability allow for the construction of innovative and energy-efficient structural designs. It enables the use of larger open spaces, reducing the need for additional structural components and materials. This not only reduces construction costs but also lowers energy consumption associated with the production and transportation of these additional materials. In conclusion, steel formwork positively impacts the overall energy efficiency of a structure through its durability, thermal conductivity, insulation properties, natural lighting and ventilation features, and its ability to enable innovative structural designs. By reducing energy consumption in various ways, steel formwork contributes to the sustainability and long-term energy efficiency of a building.

- Q: What type of steel is used in steel formwork?

- Typically, a high-strength, low-alloy (HSLA) steel is employed in steel formwork due to its excellent strength, durability, and resistance to corrosion. HSLA steel is frequently utilized in construction projects that demand a robust and enduring material capable of enduring the challenges of formwork. Moreover, the steel employed in formwork is frequently subjected to special coatings or finishes to further augment its ability to resist rust and other types of deterioration.

- Q: How does steel formwork affect the overall aesthetics of the structure?

- Steel formwork can have a significant impact on the overall aesthetics of a structure. Its sleek and smooth surface finish provides a clean and modern look, which is highly desired in contemporary architectural designs. The precision and accuracy of steel formwork also allows for intricate detailing and complex shapes to be achieved, enhancing the visual appeal of the structure. Furthermore, steel formwork enables the creation of sharp edges and crisp lines, resulting in a more refined and sophisticated appearance. This is particularly beneficial for structures with exposed concrete surfaces, as the use of steel formwork eliminates the need for additional surface treatments or finishing materials. Moreover, steel formwork offers versatility in terms of creating different textures and patterns on the concrete surface. By utilizing various surface treatments or coatings, such as acid etching or powder coating, architects and designers can further enhance the visual impact of the structure and create unique aesthetic effects. Additionally, steel formwork is known for its durability and structural integrity, ensuring that the aesthetics of the structure remains intact over time. Unlike other types of formwork, steel formwork does not warp or deform, providing a consistent and uniform appearance throughout the construction process and beyond. In summary, steel formwork positively influences the overall aesthetics of a structure by providing a sleek and modern finish, enabling intricate detailing and complex shapes, creating sharp edges and crisp lines, offering versatility in texture and pattern, and ensuring long-lasting durability.

- Q: How does steel formwork accommodate for different concrete pouring rates?

- Steel formwork can accommodate different concrete pouring rates by its ability to withstand high pressures exerted by the concrete. The strength and rigidity of steel allow it to contain and support the concrete, regardless of the speed at which it is poured. This ensures that the formwork remains stable and intact, preventing any deformations or collapses during the pouring process.

- Q: How does steel formwork contribute to the overall strength of a structure?

- Using steel panels and frames, steel formwork is a construction technique employed to create temporary molds for pouring concrete. This method offers several advantages over traditional wooden formwork, particularly in terms of strengthening a structure. Firstly, steel formwork boasts exceptional durability and resistance to wear and tear. Steel is a sturdy material capable of withstanding heavy loads and extreme weather conditions. Unlike wooden formwork, it does not warp, crack, or deteriorate over time, ensuring the structure's strength and integrity are maintained for an extended period. Furthermore, steel formwork provides superior dimensional stability compared to other materials. The precision fabrication of steel panels and frames guarantees accurate measurements and consistent shapes. This precision allows for a more even distribution of concrete, resulting in a stronger structure with reduced cracks or weaknesses. Moreover, steel formwork allows for greater flexibility in design and construction. The strength of steel permits the creation of intricate and complex structures that may not be achievable with alternative formwork materials. The versatility of steel formwork enables engineers to design structures with unique shapes and configurations, ultimately enhancing their overall strength and load-bearing capacity. Additionally, steel formwork contributes to the overall strength of a structure by offering excellent support and reinforcement during the concrete pouring process. Acting as a framework, the steel panels and frames hold the concrete in place until it solidifies and gains strength. This ensures proper and optimal curing of the concrete, resulting in a structurally sound and resilient structure. In conclusion, steel formwork plays a vital role in enhancing the overall strength of a structure. Its durability, dimensional stability, flexibility in design, and support during the concrete pouring process all contribute to creating a robust and long-lasting structure. By choosing steel formwork, construction projects can achieve higher levels of strength, durability, and structural integrity.

- Q: How is steel formwork cleaned and maintained?

- Due to its durability and reusability, steel formwork is commonly utilized in construction projects. To maintain its quality and ensure its long lifespan, it is crucial to perform regular cleaning and maintenance. Here are some guidelines for cleaning and maintaining steel formwork: 1. Eliminate concrete residue: After each usage, it is necessary to remove any concrete residue from the steel formwork. This can be accomplished by chipping away the hardened concrete with a hammer or chisel, being careful not to damage the formwork surface. 2. Utilize power washing: Once the larger pieces of concrete have been removed, a high-pressure water jet can be used for power washing. This will help dislodge any remaining concrete particles and dirt from the formwork surface. While power washing, it is important to observe appropriate safety measures such as wearing protective clothing and goggles. 3. Apply chemical cleaning: If stubborn stains or concrete deposits cannot be removed through power washing alone, a chemical cleaning solution can be employed. There are various concrete removers available in the market that can be applied to the formwork surface. It is essential to follow the manufacturer's instructions for proper usage and safety precautions. 4. Remove and prevent rust: Steel formwork is prone to rusting, which can compromise its structural integrity. Regularly inspect the formwork for any signs of rust and eliminate it using wire brushes or sandpaper. After rust removal, apply a rust-inhibiting primer or a protective coating to prevent further rusting. This should be done prior to storing the formwork to ensure its preservation. 5. Store properly: When not in use, it is important to store steel formwork in a clean and dry environment. Exposure to moisture, extreme temperatures, and corrosive substances should be avoided, as these can negatively impact the formwork's quality. Proper stacking and organization can also prevent damage and deformation during storage. Regular maintenance and cleaning are vital for the longevity and reusability of steel formwork. By adhering to these steps and taking necessary precautions during cleaning and storage, steel formwork can be preserved in optimal condition for future construction projects.

- Q: How does steel formwork handle form release agents?

- Steel formwork handles form release agents differently compared to other types of formwork, such as wood or plastic. Steel formwork typically has smooth and non-porous surfaces, which makes it easier for form release agents to be applied and spread evenly. Form release agents are substances applied to the surfaces of the formwork before pouring concrete. Their main purpose is to prevent the concrete from sticking to the formwork, facilitating easy removal of the formwork after the concrete has set. Steel formwork provides an excellent surface for form release agents to be applied. The smooth and non-absorbent nature of steel allows the release agent to form a thin film or coating on the surface, ensuring a clean separation between the concrete and the formwork. When applying form release agents on steel formwork, it is important to follow the manufacturer's instructions to ensure proper application. Typically, a sprayer or brush is used to evenly distribute the release agent onto the steel surface. It is crucial to apply an adequate amount of release agent to ensure complete coverage, as insufficient application may result in concrete sticking to the formwork. Steel formwork also has the advantage of being reusable, which means that form release agents need to be reapplied for each use. After the concrete has set, the formwork can be easily removed, and any residual form release agent can be cleaned off the steel surface. This allows the formwork to be used multiple times, reducing costs and increasing efficiency in construction projects. In summary, steel formwork handles form release agents effectively due to its smooth and non-porous surface. The even application of form release agents on steel formwork ensures a clean separation between the concrete and the formwork, facilitating easy removal after the concrete has set. The reusability of steel formwork also allows for multiple applications of form release agents, reducing costs and increasing efficiency in construction projects.

- Q: How does steel formwork handle concrete vibration and air entrapment?

- Steel formwork is highly effective in handling concrete vibration and minimizing air entrapment during the pouring and curing process. Firstly, steel formwork is known for its high strength and rigidity, which allows it to withstand the intense vibrations caused by concrete compaction. When concrete is poured into steel formwork, the formwork itself acts as a barrier, preventing excessive movement or deformation that could lead to the formation of voids or air pockets. This ensures that the concrete is evenly distributed and compacted throughout the structure. Additionally, steel formwork is designed with tight joints and smooth surfaces, which helps in reducing air entrapment. The joints are tightly sealed to prevent any leakage, which could result in air being trapped within the concrete. This is particularly important as air pockets can weaken the structural integrity and durability of the concrete. The smooth surfaces also aid in the easy flow and consolidation of the concrete, reducing the chances of air entrapment. Furthermore, steel formwork can be easily customized and adjusted to fit the specific requirements of the construction project. This allows for precise and accurate placement of the formwork, ensuring that the concrete is poured and compacted in the desired manner. By having complete control over the formwork, the risk of air entrapment can be minimized, resulting in a more durable and reliable concrete structure. In conclusion, steel formwork is an excellent choice for handling concrete vibration and air entrapment. Its strength, rigidity, tight joints, and smooth surfaces provide the necessary stability and control during the pouring and compaction process. By using steel formwork, construction professionals can ensure that the concrete is properly consolidated and free from air pockets, resulting in a high-quality and long-lasting structure.

- Q: Can steel formwork be used for staircase construction?

- Yes, steel formwork can be used for staircase construction. Steel formwork is a versatile and durable material that is commonly used in construction projects, including staircase construction. It provides a strong and stable structure for pouring concrete and ensures precise and accurate shaping of the staircase. Additionally, steel formwork is reusable, making it a cost-effective choice for repetitive construction processes like staircase construction. It also offers flexibility in design, allowing for the creation of various staircase shapes and sizes. Overall, steel formwork is a suitable choice for staircase construction due to its strength, durability, reusability, and design flexibility.

Send your message to us

Stair Tower for Formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords