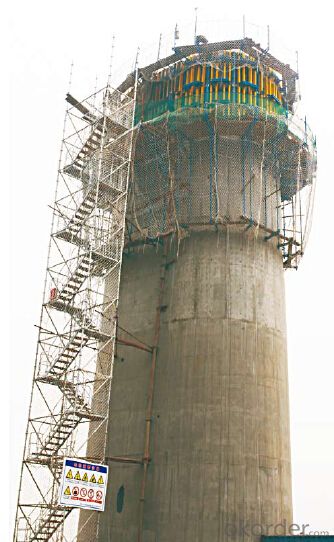

Stair tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: What are the safety precautions when working with steel formwork?

- When working with steel formwork, it is important to follow several safety precautions to ensure the well-being of workers. These precautions include wearing personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and steel-toed boots. It is also crucial to inspect the formwork for any damages or defects before using it, as well as to secure it properly to prevent collapse or movement during construction. Adequate training and supervision should be provided to workers, and they should be cautious of potential hazards such as sharp edges, heavy lifting, and working at heights. Regular communication and adherence to safety protocols are key to minimizing accidents and ensuring a safe working environment.

- Q: How does steel formwork impact the overall project management?

- Steel formwork can have a significant impact on the overall project management. Firstly, steel formwork is known for its durability, strength, and reusability, which allows for multiple uses on different projects. This reduces the need for frequent replacements or repairs, saving both time and money. Additionally, steel formwork offers greater accuracy and precision in construction, resulting in a higher quality end product. It also enables faster construction due to its ease of assembly and disassembly. Moreover, steel formwork provides a safer working environment for laborers, as it is sturdier and more resistant to deformation. Overall, steel formwork positively impacts project management by enhancing efficiency, reducing costs, improving construction quality, and ensuring worker safety.

- Q: Can steel formwork be used for both horizontal and vertical concrete placement?

- Yes, steel formwork can be used for both horizontal and vertical concrete placement. Steel formwork is a versatile and durable solution for creating molds or frames that hold wet concrete in the desired shape until it sets and hardens. This type of formwork is commonly used in construction projects for various applications, including both horizontal and vertical concrete placement. Steel forms are strong enough to withstand the weight and pressure of the concrete, making them suitable for vertical applications such as walls, columns, and beams. Additionally, steel formwork can be easily adjusted or modified to accommodate different shapes and sizes, making it ideal for horizontal placements like slabs, floors, and pavement. Overall, steel formwork offers flexibility, strength, and stability, making it suitable for a wide range of concrete placement requirements.

- Q: How does steel formwork handle different concrete air content requirements?

- Steel formwork is a durable and versatile construction material that can effectively handle different concrete air content requirements. Concrete air content refers to the amount of air trapped within the concrete mixture, which is crucial for various reasons such as improving workability, durability, and resistance to freezing and thawing cycles. Steel formwork is designed to provide a strong and rigid structure to contain and shape the concrete during the pouring and curing process. Since the formwork is made of steel, it is not permeable, meaning it does not allow air to pass through. This prevents any air from escaping the concrete mixture, ensuring that the desired air content is maintained. To handle different concrete air content requirements, steel formwork can be customized or adjusted accordingly. For instance, if a higher air content is required, the formwork can be designed with additional space or voids to accommodate the desired amount of air within the concrete. On the other hand, if a lower air content is needed, the formwork can be designed to minimize any potential air entrapment by ensuring tight connections and smooth surfaces. Additionally, steel formwork can also be used in conjunction with other techniques to control the air content in concrete. For example, the formwork can be combined with the use of air-entraining admixtures, which are additives that are mixed with the concrete to purposely introduce air bubbles. These admixtures create a more uniform distribution of air throughout the concrete, and the steel formwork helps to retain this air during the pouring and curing process. In summary, steel formwork is well-suited for handling different concrete air content requirements due to its impermeability and customizable nature. It provides a reliable and robust structure to contain the concrete while ensuring that the desired air content is maintained, either by creating additional space for higher air content or by minimizing air entrapment for lower air content. Additionally, it can be used in conjunction with other techniques such as air-entraining admixtures to further control the air content in concrete.

- Q: Is steel formwork suitable for all types of construction projects?

- Steel formwork is a versatile and widely used construction material that is suitable for a variety of construction projects. However, it may not be suitable for all types of construction projects. Steel formwork offers several advantages such as durability, reusability, and high load-bearing capacity. It can be used for both large-scale and small-scale projects, including residential, commercial, industrial, and infrastructure projects. Steel formwork is particularly well-suited for projects that require a high degree of precision and quality finish, such as high-rise buildings, bridges, and tunnels. However, there are certain factors to consider when determining the suitability of steel formwork for a specific construction project. One important factor is the project's budget. Steel formwork tends to have a higher initial cost compared to other types of formwork materials such as timber or aluminum. Therefore, it may not be suitable for projects with tight budget constraints. Another factor to consider is the project's timeline. Steel formwork requires skilled labor and time for assembly, disassembly, and transportation. This may result in longer construction periods, which may not be feasible for projects with strict deadlines. The complexity of the project is also an important factor to consider. Steel formwork is highly adaptable and can be custom-made for specific project requirements. However, if the project involves irregular or complex shapes, it may be more challenging and time-consuming to construct steel formwork compared to other types of formwork materials. Additionally, the environmental conditions of the construction site should be taken into account. Steel formwork is durable and can withstand harsh weather conditions. However, it may not be suitable for projects in coastal areas or locations with high humidity, as steel is susceptible to corrosion. In conclusion, while steel formwork is suitable for a wide range of construction projects, its suitability should be evaluated on a case-by-case basis. Considerations such as budget, timeline, complexity of the project, and environmental conditions should be taken into account to determine if steel formwork is the most suitable choice for a specific construction project.

- Q: What are the different types of formwork spacers used in steel formwork?

- In steel formwork, there are various types of formwork spacers that are commonly used. These spacers are essential components in the construction process as they help maintain the desired spacing between the formwork and reinforcement, ensuring the structural integrity of the concrete structure. Here are some of the different types of formwork spacers used in steel formwork: 1. Plastic Spacers: Plastic spacers are widely used in steel formwork due to their lightweight, durability, and ease of installation. These spacers are typically made from high-quality plastic materials and come in various shapes and sizes to accommodate different reinforcement requirements. 2. Steel Spacers: Steel spacers are another common type of formwork spacer used in steel formwork applications. They are usually made from high-strength steel and are capable of withstanding higher loads. Steel spacers are ideal for heavy-duty applications where additional strength and durability are required. 3. Rubber Spacers: Rubber spacers are used in steel formwork to provide a cushioning effect and prevent direct contact between the reinforcement and the formwork. These spacers are suitable for applications where vibration or movement is expected, as they help absorb shocks and reduce the risk of damage. 4. Concrete Spacers: Concrete spacers are primarily used in precast concrete applications. They are made from concrete and act as support structures to maintain the correct spacing between the formwork and reinforcement. Concrete spacers are durable, easy to install, and provide excellent stability during the casting process. 5. Combination Spacers: Combination spacers are versatile spacers that combine different materials such as plastic and steel to provide enhanced strength and stability. These spacers are designed to meet specific project requirements and offer a cost-effective solution for various steel formwork applications. It is important to choose the appropriate type of formwork spacer based on the specific requirements of the project, including load capacity, spacing requirements, and environmental conditions. Consulting with a structural engineer or construction professional can help ensure the correct selection and installation of formwork spacers for optimal performance and safety.

- Q: How is steel formwork assembled?

- Steel formwork, also known as steel shuttering, is a popular choice for construction projects due to its durability and reusability. The assembly process of steel formwork involves a series of steps to ensure a secure and stable structure. Firstly, the steel formwork panels are laid out on the construction site in the desired configuration. These panels are typically made of high-quality steel and come in various sizes and shapes to accommodate different project requirements. Next, the panels are interconnected using different types of fastening systems, such as clamps, bolts, or pins. This ensures that the formwork remains rigid and stable during concrete pouring and curing. The fastening system used may vary depending on the specific design and requirements of the project. Once the panels are securely connected, adjustable props or braces are installed to provide additional support and stability to the formwork. These props are usually made of steel and can be adjusted in height to accommodate different concrete pouring heights. After the formwork structure is assembled and properly supported, it is ready for concrete pouring. The formwork acts as a mold, containing the fresh concrete until it hardens and gains sufficient strength. The concrete is poured into the formwork using pumps or buckets, and then it is vibrated or compacted to eliminate air pockets and ensure proper adhesion. Once the concrete has cured and gained sufficient strength, the formwork is carefully dismantled. The dismantling process involves removing the props, unfastening the panels, and carefully disassembling the formwork structure. The dismantled steel formwork can then be cleaned, inspected, and reused for future construction projects, making it a cost-effective and sustainable choice. Overall, the assembly of steel formwork involves laying out and connecting the steel panels, installing adjustable props for support, pouring concrete, and finally dismantling the formwork structure. This process ensures a robust and stable formwork system that facilitates efficient and high-quality concrete construction.

- Q: What are the common safety certifications for steel formwork systems?

- Steel formwork systems can obtain various safety certifications to guarantee the highest safety and quality standards. Some of the most well-known certifications are as follows: 1. ISO 9001: This certification ensures that the manufacturer of the steel formwork system adheres to an internationally recognized quality management system. It focuses on meeting customer satisfaction, continuously improving processes, and complying with regulatory requirements. 2. OHSAS 18001: Specifically aimed at occupational health and safety management systems, this certification demonstrates that the manufacturer has implemented effective safety policies, procedures, and controls to prevent work-related injuries and illnesses. 3. CE Marking: This certification is compulsory for steel formwork systems sold in the European Union (EU) and verifies that the product meets essential health, safety, and environmental protection requirements set by EU legislation. 4. ANSI/ASSE A10.9: Developed by the American National Standards Institute (ANSI), this standard provides guidelines for the design, use, and maintenance of formwork systems, including steel formwork. Complying with this standard ensures the system's safety and suitability for construction projects. 5. UL Certification: Underwriters Laboratories (UL), a globally recognized safety certification organization, grants UL Certification to steel formwork systems that have undergone rigorous testing and meet specific safety standards. It is important to note that the required safety certifications may vary depending on the country and region. Therefore, it is recommended to consult local regulations and standards applicable to the construction project before selecting a steel formwork system.

- Q: How does steel formwork affect the overall timeline of a construction project?

- The overall timeline of a construction project can be significantly influenced by the use of steel formwork. One of the main advantages of steel formwork is its durability and reusability. Unlike traditional timber formwork, steel formwork can be utilized multiple times, reducing the time required for constructing and dismantling formwork for each concrete pour. Furthermore, the strength and rigidity of steel formwork enable faster construction cycles. Its ability to withstand higher concrete pressure allows for quicker pouring and setting of concrete, resulting in shorter curing times. This, in turn, permits subsequent construction activities to commence earlier, ultimately accelerating the overall project timeline. Another noteworthy feature of steel formwork is its precision and dimensional stability. It provides a smooth and accurate surface finish, eliminating the need for additional plastering or leveling work. This saves time and reduces the number of construction activities required, thus further enhancing the project timeline. Moreover, steel formwork is typically prefabricated, meaning it is manufactured off-site and delivered ready for assembly at the construction site. This considerably reduces on-site construction time, as the formwork can be swiftly erected and adjusted to the desired shape and dimensions. This timely installation ensures that other trades can progress with their work without delays, ultimately speeding up the overall construction process. However, it is important to acknowledge that the initial setup time for steel formwork may be longer compared to other formwork types, as it necessitates careful planning and coordination. The formwork design must be accurately calculated, and any modifications or adjustments may require additional time. Nevertheless, the time saved during subsequent concrete pours and other construction activities usually compensates for this initial setup period. In conclusion, steel formwork has a positive impact on the overall timeline of a construction project by reducing the time spent on constructing and dismantling formwork, enabling faster concrete pouring and curing, providing a precise and finished surface, and facilitating quick and efficient on-site assembly. Its durability and reusability contribute to a more efficient and timely construction process, resulting in a shorter overall project duration.

- Q: How does steel formwork handle high concrete pressures?

- Steel formwork is known for its excellent strength and durability, making it highly capable of handling high concrete pressures. When subjected to significant pressure, steel formwork retains its shape and structure, providing a stable and reliable framework for the poured concrete. The strength of steel formwork lies in its ability to withstand the immense forces exerted by the weight and fluidity of the concrete. Steel is inherently strong and has a high load-bearing capacity, enabling it to resist the pressure exerted by the concrete during the pouring and curing process. Moreover, steel formwork is designed with reinforcement and bracing systems that further enhance its ability to handle high concrete pressures. Reinforcements, such as steel bars or mesh, are strategically placed within the formwork structure to provide additional support and prevent any deformation or failure. These reinforcements distribute the stress evenly across the formwork, minimizing the risk of damage due to excessive pressure. Additionally, steel formwork is often designed with strong connection points and interlocking mechanisms. These features ensure that the individual components of the formwork system remain securely connected, preventing any collapse or failure under high concrete pressures. The interlocking nature of steel formwork also helps to maintain the integrity of the structure and prevent any leakage or seepage of the concrete. In summary, steel formwork is specifically engineered to handle high concrete pressures effectively. The inherent strength of steel, combined with reinforcement and bracing systems, ensures that the formwork can withstand the immense forces exerted by the weight and fluidity of the concrete. Its ability to retain its shape and stability under pressure makes steel formwork a reliable and widely used choice in construction projects requiring high concrete pressures.

Send your message to us

Stair tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords