Stainless Steel Sheet 304 in Top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Product Description

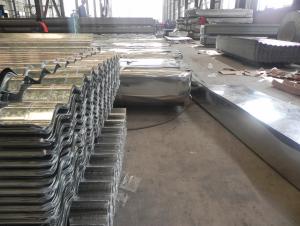

Stainless steel sheet Detailed introduction

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

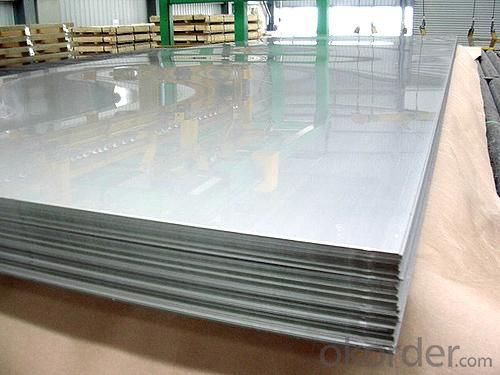

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

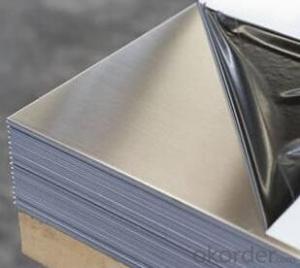

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for decorative purposes?

- Yes, stainless steel sheets can definitely be used for decorative purposes. Stainless steel is known for its sleek and modern appearance, making it a popular choice for various decorative applications. It is often used in interior design, architecture, and even art installations. Stainless steel sheets can be customized to create unique patterns, textures, and finishes, making them suitable for creating eye-catching and visually appealing decorative elements. Additionally, stainless steel is highly durable, corrosion-resistant, and easy to maintain, making it a practical choice for both indoor and outdoor decorative applications.

- Q: Are stainless steel sheets suitable for elevator handrails?

- Elevator handrails can be made from stainless steel sheets, which are suitable due to their durability, resistance to corrosion, and attractive look. Handrails in elevators face constant use and exposure to various environmental factors, including moisture and fingerprints. However, stainless steel is highly resistant to corrosion, ensuring that the handrails last for a long time without the need for maintenance. Moreover, stainless steel has a sleek and modern appearance that complements the overall elevator design. Its smooth surface is easy to clean and maintain, making it a hygienic option for handrails in public areas. In summary, stainless steel sheets are an excellent choice of material for elevator handrails.

- Q: Can stainless steel sheets be used for kitchen utensils?

- Yes, stainless steel sheets can be used for kitchen utensils. Stainless steel is a popular choice for kitchen utensils because it is durable, easy to clean, and resistant to rust and corrosion. Stainless steel sheets can be shaped and formed into various utensils such as spoons, forks, knives, spatulas, and more. Additionally, stainless steel is non-reactive, meaning it does not leach any harmful chemicals into food, making it a safe option for cooking and eating utensils. Overall, stainless steel sheets are a great material choice for kitchen utensils due to their strength, hygiene, and longevity.

- Q: How do you determine the thickness of stainless steel sheets required for a specific application?

- To determine the thickness of stainless steel sheets required for a specific application, several factors need to be considered. These factors include the type and magnitude of the load or stress the sheet will be subjected to, the desired level of durability and strength, the specific application requirements, and any applicable industry standards or regulations. Engineering calculations, material testing, and consultation with experts in the field can help in determining the appropriate thickness for the stainless steel sheets needed for the specific application.

- Q: How do I prevent intergranular corrosion on stainless steel sheets?

- To prevent intergranular corrosion on stainless steel sheets, there are several steps that can be taken: 1. Opt for the appropriate stainless steel grade: Choose stainless steel grades that are specifically designed to resist intergranular corrosion, such as 304L, 316L, or 321. These grades have a lower carbon content, which minimizes the formation of chromium carbides at grain boundaries. 2. Apply heat treatment: After fabrication or welding, subject the stainless steel sheets to a solution annealing or post-weld heat treatment process. This treatment eliminates any chromium carbides that may have formed during welding or high-temperature processing, effectively preventing intergranular corrosion. 3. Avoid high temperature exposure: It is crucial to avoid subjecting stainless steel sheets to temperatures between 450 to 850 degrees Celsius (842 to 1562 degrees Fahrenheit) for extended periods. Prolonged exposure to such temperatures can lead to the formation of chromium carbides at the grain boundaries, rendering the stainless steel susceptible to intergranular corrosion. 4. Utilize proper welding techniques: When welding stainless steel sheets, it is important to employ low heat input and minimize the duration of exposure to high temperatures. These measures help reduce the formation of chromium carbides and preserve the corrosion resistance of the stainless steel. 5. Employ pickling and passivation: After fabrication or welding, ensure that the stainless steel sheets undergo thorough pickling and passivation. Pickling removes any surface contaminants, while passivation forms a protective oxide layer that prevents intergranular corrosion. 6. Regularly maintain and clean: To prevent potential corrosion, it is essential to keep the stainless steel sheets clean and free from contaminants. Regularly clean the surfaces using mild detergents and avoid the use of harsh chemicals or abrasive materials that may damage the protective oxide layer. By following these preventative measures, the risk of intergranular corrosion on stainless steel sheets can be significantly reduced, allowing for the preservation of their corrosion resistance properties and an extended lifespan.

- Q: Can stainless steel sheets be used for staircase railings?

- Yes, stainless steel sheets can be used for staircase railings. Stainless steel is a popular choice for staircase railings due to its durability, strength, and resistance to corrosion. Stainless steel sheets can be cut, shaped, and welded to create a variety of railing designs and styles. They can also be finished in different ways, such as brushed or polished, to achieve the desired aesthetic appearance. Stainless steel railings are not only aesthetically pleasing but also provide a safe and sturdy support for staircases.

- Q: How are stainless steel sheets manufactured?

- Stainless steel sheets are manufactured through a multi-step process that involves several key stages. The production begins with the melting of raw materials, including iron ore, chromium, and nickel, in an electric arc furnace. This process helps to eliminate impurities and create a molten metal. Once the molten metal is obtained, it is cast into slabs or billets. These slabs are then hot rolled, which involves passing them through a series of rollers to reduce their thickness and increase their length. This initial rolling process also helps in refining the grain structure of the steel, making it more uniform. After hot rolling, the steel is pickled and annealed to remove any scale or impurities formed during the initial rolling process. Pickling involves immersing the steel in a bath of acid to remove the surface oxide layer, while annealing is a heat treatment process that helps to reduce internal stresses and improve the steel's ductility. Following pickling and annealing, the steel is cold rolled. Cold rolling involves passing the annealed steel through a set of rollers at room temperature to further reduce its thickness and improve its surface finish. This process also imparts the desired mechanical properties to the stainless steel sheets. Once the desired thickness is achieved through cold rolling, the stainless steel sheets are subjected to various finishing processes. These may include surface treatments like polishing, embossing, or etching to enhance the appearance and texture of the sheets. Additionally, the sheets can be cut to size using shearing or laser cutting techniques. Finally, the stainless steel sheets undergo quality control checks to ensure they meet the required specifications. This includes inspecting the dimensions, surface finish, and mechanical properties of the sheets. Once approved, the sheets are ready for packaging and distribution to various industries that utilize stainless steel in their applications. Overall, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, pickling, annealing, cold rolling, and finishing. This meticulous process ensures the production of high-quality stainless steel sheets that possess excellent corrosion resistance, strength, and aesthetic appeal.

- Q: Are stainless steel sheets suitable for medical equipment?

- Yes, stainless steel sheets are suitable for medical equipment. Stainless steel is a popular choice for medical equipment due to its excellent corrosion resistance and durability. It is easy to clean and sterilize, making it suitable for use in healthcare settings where cleanliness and hygiene are crucial. Additionally, stainless steel has a high strength-to-weight ratio, allowing for the construction of lightweight yet sturdy medical equipment. It also has a low magnetic permeability, making it ideal for applications where electromagnetic interference needs to be minimized. Overall, stainless steel sheets are a reliable and practical choice for manufacturing medical equipment.

- Q: Are stainless steel sheets suitable for nuclear power plants?

- Yes, stainless steel sheets are suitable for nuclear power plants. Stainless steel is a highly durable material that possesses excellent corrosion resistance, mechanical strength, and heat resistance properties, which are crucial requirements for the harsh and demanding environment of nuclear power plants. Additionally, stainless steel's ability to withstand high temperatures and maintain its structural integrity makes it a reliable choice for various components, such as piping, vessels, and heat exchangers, within nuclear power plants.

- Q: Are stainless steel sheets suitable for decorative purposes?

- Stainless steel sheets are a perfect choice for decorative purposes. They possess a sleek and contemporary appearance, which adds a touch of elegance and sophistication to any given space. The smooth and reflective surface of stainless steel creates a visually pleasing aesthetic that enhances the overall look and feel of a room. Furthermore, stainless steel is incredibly durable and corrosion-resistant, making it an excellent long-term option for decorative use. The versatility of stainless steel sheets allows them to be utilized in various decorative forms, including wall panels, backsplashes, countertops, and even furniture. Regardless of whether they are used in residential or commercial settings, stainless steel sheets can be employed to create remarkable and attention-grabbing decorative elements that perfectly complement any interior design style.

Send your message to us

Stainless Steel Sheet 304 in Top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords