Stainless Steel Sheet 201 202 304 316 310

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Factory direct sale 201 202 304 304L 316 316L 321 310S 309S 430 904L stainless steel sheet

Features:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information:

1. Steel grade: 321

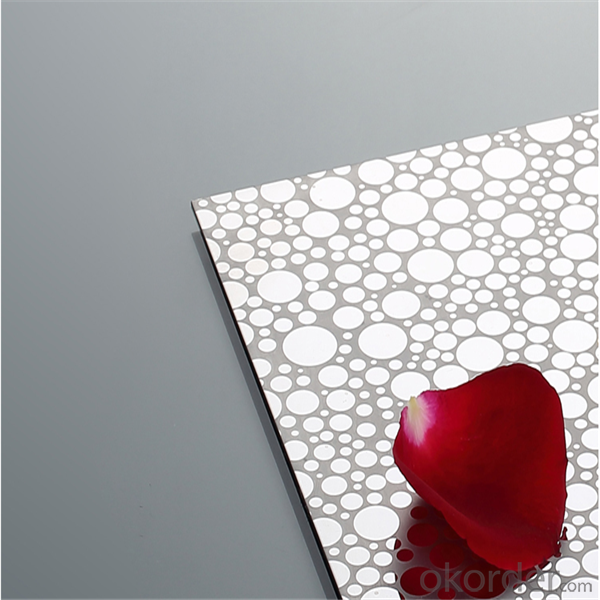

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

9. Advantage: Colorful, showing the splendor of your quality, wear-resistant as well, strong corrosion resistance, anti-rust property and decorative effect, durable and beautiful in good taste.

10. Supplier Product Code: SDJM

11. Competitive Advantages of the product

1) Stainless Steel Decorative Sheet

2) Customize pattern and color coating

3) Advantage: Various patterns, splendid decorative effect, fashionable design

4) Surface finish: Mirror, 2b, no.1, no.4, 6k, 8k, polished, etc

1. Specifications about stainless steel sheet

Commodity | stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 5 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

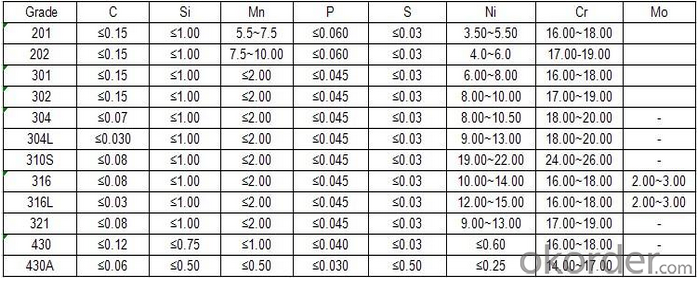

2. Chemical Composition about stainless steel sheet

3. Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

- Q: What is the weight of a stainless steel sheet?

- The weight of a stainless steel sheet may differ based on its dimensions and thickness. Stainless steel possesses a density of approximately 8 grams per cubic centimeter. Thus, in order to compute the weight of a sheet, it is necessary to possess knowledge of its length, width, and thickness. By multiplying these dimensions together and subsequently multiplying by the density, the weight of the stainless steel sheet can be determined. For instance, a stainless steel sheet measuring 4 feet by 8 feet and with a 1/8 inch thickness would weigh approximately 56 pounds. It is crucial to acknowledge that these calculations are only approximations and may slightly fluctuate based on the precise composition and grade of the stainless steel.

- Q: Can stainless steel sheets be used for mezzanine flooring?

- Indeed, mezzanine flooring can be constructed using stainless steel sheets. Being a robust and corrosion-resistant substance, stainless steel proves itself appropriate for diverse purposes, such as flooring. With its exceptional durability and ability to endure substantial weights, stainless steel emerges as an optimal choice for mezzanine structures. Moreover, the advantage of hassle-free cleaning and maintenance guarantees a sanitary and visually appealing flooring alternative.

- Q: How do you prevent galling on stainless steel sheets?

- To prevent galling on stainless steel sheets, it is important to use lubricants or anti-seize compounds during the manufacturing or assembly process. This helps reduce friction and surface adhesion, minimizing the risk of galling. Additionally, using proper cutting tools and techniques, such as slow speeds and low feed rates, can also help prevent galling.

- Q: Can stainless steel sheets be used for water purification systems?

- Yes, stainless steel sheets can be used for water purification systems. Stainless steel is highly corrosion resistant and does not react with water, making it suitable for use in water purification systems where contact with water is constant. It also has excellent mechanical properties and can withstand high pressures, making it a durable and reliable material choice in such applications.

- Q: What are the different types of stainless steel sheet surface finishes available?

- Some of the different types of stainless steel sheet surface finishes available include: 1. No.1 Finish: This is a rough, dull surface finish with visible grain lines. 2. No.2B Finish: It has a smooth, bright finish that is commonly used for appliances and architectural applications. 3. No.4 Finish: This finish has a brushed appearance with fine grain lines and is often used in decorative applications. 4. No.8 Mirror Finish: It provides a highly reflective surface that is used for decorative purposes. 5. Satin Finish: It has a smooth, silky appearance with low reflectivity and is commonly used in architectural and decorative applications. 6. Brushed Finish: This finish has a consistent linear grain pattern created by brushing the surface with abrasive materials. 7. Embossed Finish: It features raised patterns or textures on the surface, providing a decorative and tactile effect. 8. Bead Blast Finish: It creates a uniform, matte surface texture by blasting stainless steel sheets with fine glass beads. 9. Etched Finish: This finish involves chemically etching the surface to create patterns or designs. 10. Colored Finish: Stainless steel sheets can be coated or treated to achieve various colors and finishes, allowing for customization and aesthetic appeal.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness of stainless steel sheets varies depending on the specific type and grade of stainless steel. Typically, stainless steel sheets are available in thicknesses ranging from 0.4mm to 6.0mm. Thinner sheets are commonly utilized for flexible and lightweight applications, whereas thicker sheets are typically employed for structural purposes requiring increased strength and durability. It is worth mentioning that customized thicknesses can be manufactured to meet specific project requirements.

- Q: Are stainless steel sheets resistant to alkaline solutions?

- Yes, stainless steel sheets are generally resistant to alkaline solutions. Stainless steel is known for its corrosion-resistant properties, and it can withstand exposure to a wide range of chemicals, including alkalis. The high chromium content in stainless steel forms a protective oxide layer on the surface, which helps to prevent corrosion and deterioration. However, it is important to note that the resistance of stainless steel to alkaline solutions may vary depending on the specific grade and composition of the stainless steel. In some cases, prolonged exposure to highly concentrated alkaline solutions or exposure to certain aggressive alkaline substances may cause damage to the stainless steel surface. Therefore, it is advisable to consult with the manufacturer or supplier to ensure the appropriate grade of stainless steel is selected for specific alkaline applications.

- Q: Do stainless steel sheets require any special handling during installation?

- Yes, stainless steel sheets do require special handling during installation. Here are a few important considerations: 1. Avoid Contamination: Stainless steel is prone to contamination from various sources, such as carbon steel, dirt, or grease. It is crucial to ensure that the installation area is clean and free from any potential contaminants. Tools used during installation should also be clean and free from other metals. 2. Protection from Scratches: Stainless steel sheets are susceptible to scratching during installation. It is important to handle them with care and use protective coverings or wraps to prevent any scratches or damage. Additionally, using non-abrasive tools and avoiding dragging or sliding the sheets across surfaces can help maintain their integrity. 3. Proper Fixing Techniques: Stainless steel sheets are typically secured using mechanical fasteners or adhesives. It is essential to follow the manufacturer's recommendations or industry best practices for the specific installation method. This includes using the correct type and size of fasteners and ensuring they are properly tightened without over-torquing, which can cause damage. 4. Expansion and Contraction: Stainless steel sheets can expand or contract with changes in temperature. During installation, it is necessary to allow for this movement by providing adequate clearance or using expansion joints where required. Failing to account for thermal expansion can lead to buckling, warping, or stress on the sheets. 5. Avoiding Galvanic Corrosion: Stainless steel sheets should not come into direct contact with dissimilar metals, especially those with higher galvanic potential, as it can cause galvanic corrosion. Using compatible materials and insulating stainless steel sheets from direct contact with other metals can help prevent this type of corrosion. By following these special handling guidelines, stainless steel sheets can be installed correctly, maintaining their aesthetic appeal and durability over time.

- Q: What is the minimum thickness available for stainless steel sheets?

- The minimum thickness available for stainless steel sheets can vary depending on the specific grade and manufacturing capabilities, but it is typically around 0.4 millimeters (0.0157 inches) or even thinner.

- Q: How do you remove water spots from stainless steel sheets?

- To remove water spots from stainless steel sheets, you can mix equal parts vinegar and water in a spray bottle and spray the affected areas. Let it sit for a few minutes, then wipe it off with a soft cloth. Additionally, you can use a stainless steel cleaner or polish specifically designed for removing water spots.

Send your message to us

Stainless Steel Sheet 201 202 304 316 310

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords