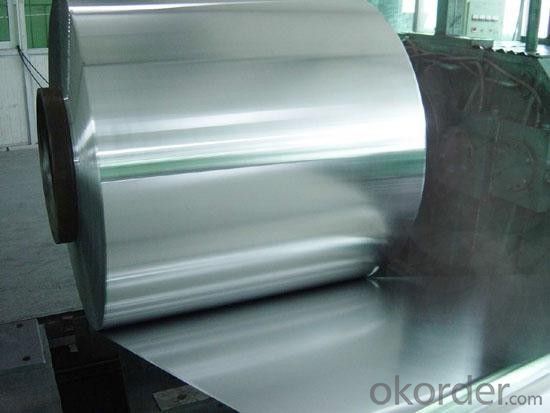

Stainless Steel Sheet and Plate with good treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of stainless steel

304 stainless Steel Plate

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

TISCO stainless Steel Plate 304/NO.1 finished

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

Delivery short and low cost advantage.

Description of stainless steel:

stainless steel plate,hot rolled stainless steel plate,cold rolled stainless steel plate,stainless steel sheet,steel sheet,sheet

Material of stainless steel:

304,304L,309S,310S,316,316L,316Ti,317L,317L,321,347H,409,409L,410S,420,430,201,202,etc.

Thickness of stainless steel:

From 0.3mm to 100mm

Width of stainless steel:

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm,2500mm or as your requirement

Length of stainless steel:

2000mm,2438mm,2500mm,6000mm,6096mm or as your requirement

Application of stainless steel:

Stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Our company has cooperative relation between the domestic agents. Stainless steel plate can be made accordingto the customers requirements. Fasten delivery. Quality assured.Welcome to order more.

Contacts

If you have any question,please feel free to contact us.

- Q: Can stainless steel sheets be used for hygienic environments?

- Stainless steel sheets are indeed suitable for hygienic environments. This is because stainless steel possesses certain inherent properties that render it highly resistant to corrosion, heat, and chemical damage, thus making it a popular choice for such environments. Its surface is smooth and non-porous, which facilitates easy cleaning and prevents the accumulation of bacteria, mold, or other contaminants. Furthermore, stainless steel is non-reactive and does not release any harmful substances, making it ideal for sensitive environments like food processing facilities, hospitals, pharmaceutical labs, and cleanrooms. Moreover, stainless steel is both durable and long-lasting, ensuring excellent hygiene and cleanliness for extended periods. All in all, stainless steel sheets are a dependable and hygienic option for various applications in environments that prioritize cleanliness and sanitation.

- Q: What are the limitations of using stainless steel sheets?

- Some limitations of using stainless steel sheets include their high initial cost, susceptibility to scratching, potential for corrosion in certain environments, and difficulty in shaping complex designs. Additionally, stainless steel sheets are relatively heavy, which can be a disadvantage in certain applications where weight is a concern.

- Q: Can the tile be directly attached to the stainless steel plate?

- The best use of woodworking special adhesive, decorative materials shop sell, otherwise not durable, the best post also find a professional carpenter to paste. Stainless steel is recommended with 304, once and for all. If you want to use glass glue cheaply, use neutral glass adhesive.

- Q: Are stainless steel sheets suitable for chemical storage tanks?

- Yes, stainless steel sheets are suitable for chemical storage tanks. Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for storing various chemicals. It is resistant to many corrosive substances, including acids, alkalis, and solvents, which are commonly stored in chemical storage tanks. Stainless steel sheets also have a high strength-to-weight ratio, allowing for the construction of tanks that can withstand the pressure and weight of the chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storing chemicals. Overall, stainless steel sheets are a reliable and suitable material for chemical storage tanks.

- Q: Can stainless steel sheets be used for heat exchangers?

- Indeed, heat exchangers can utilize stainless steel sheets as a viable option. The preference for stainless steel in heat exchangers arises from its exceptional corrosion resistance, durability, and exemplary heat transfer characteristics. This material exhibits exceptional resilience against high temperatures and remains impervious to both chemical and physical harm, rendering it suitable for a diverse range of industrial applications. Moreover, the malleability of stainless steel sheets allows for effortless fabrication into diverse forms and dimensions, facilitating personalized customization to fulfill precise heat exchanger prerequisites.

- Q: Are stainless steel sheets suitable for brewery equipment?

- Yes, stainless steel sheets are highly suitable for brewery equipment. Stainless steel is a preferred material in the brewing industry due to its many beneficial properties. Firstly, stainless steel is resistant to corrosion, making it ideal for equipment that comes into contact with liquids and chemicals used in the brewing process. This corrosion resistance helps maintain the quality and purity of the beer being brewed. Additionally, stainless steel is easy to clean and sanitize, which is crucial in maintaining hygiene standards in a brewery. It is non-porous, meaning it does not absorb or retain odors, flavors, or bacteria, ensuring the beer is not contaminated during production. Stainless steel also has a smooth surface, preventing the buildup of bacteria or other contaminants that could affect the quality of the beer. Furthermore, stainless steel is durable and long-lasting, able to withstand the demanding conditions of a brewery environment, including high temperatures, moisture, and constant use. This durability ensures that brewery equipment made from stainless steel sheets will have a longer lifespan, reducing the need for frequent replacement or repairs. Overall, stainless steel sheets are an excellent choice for brewery equipment due to their corrosion resistance, ease of cleaning, sanitation properties, and durability. Using stainless steel in brewery equipment helps maintain the quality and purity of the beer, ensuring a better end product for consumers.

- Q: What are the different types of edges available for stainless steel sheets?

- There are several different types of edges available for stainless steel sheets, each with its own specific purpose and aesthetic appeal. Here are some of the common edge types: 1. Mill Edge: This is the standard edge finish produced by the mill, which is often considered the most cost-effective option. It has a relatively smooth, unfinished appearance. 2. Slit Edge: This edge is achieved by cutting the stainless steel sheet along its length, resulting in a straight edge with slight burrs. It is commonly used for thinner gauges of stainless steel. 3. Deburred Edge: This edge is created by removing any burrs or sharp edges from the slit edge, resulting in a smoother finish that is safer to handle. It is commonly used in applications where safety is a concern, such as food processing or medical equipment. 4. Rounded Edge: This edge is achieved by rounding off the sharp corners of the stainless steel sheet. It provides a more aesthetically pleasing look and also improves safety by eliminating sharp edges. 5. Beveled Edge: This edge is created by cutting a diagonal bevel along the edge of the stainless steel sheet. It is often used for decorative purposes and can add a touch of elegance to the finished product. 6. Rolled Edge: This edge is formed by rolling the stainless steel sheet under high pressure, resulting in a smooth, curved edge. It is commonly used in applications where a seamless look is desired, such as architectural projects or automotive components. Overall, the choice of edge type for stainless steel sheets depends on the specific requirements of the application, including functionality, safety, and aesthetics. It is important to consider these factors in order to select the most suitable edge type for the desired end use.

- Q: Are stainless steel sheets resistant to alkalis?

- Yes, stainless steel sheets are generally resistant to alkalis. Stainless steel is known for its corrosion resistance, and it has a high resistance to a wide range of chemicals, including alkalis. This resistance is due to the presence of chromium in the alloy, which forms a protective oxide layer on the surface of the stainless steel, preventing the alkalis from corroding or damaging the material. However, it is important to note that the level of resistance may vary depending on the specific grade and composition of the stainless steel.

- Q: What is stainless steel AB board, please?

- The 2B board is basically a matt surface, according to a BA object, in approximate mirror, can more clearly illuminate the object (a little paste).

- Q: Can stainless steel sheets be used for stadium seating?

- Certainly! Stadium seating can indeed utilize stainless steel sheets. This particular material boasts durability and resistance against corrosion, rendering it a fitting choice for outdoor purposes such as stadium seating. It can endure various weather conditions, be it rain, snow, or harmful UV rays, without succumbing to deterioration or rust. By manipulating stainless steel sheets, one can fashion them into diverse seating structures, thus presenting a robust and enduring seating solution for stadiums. Furthermore, stainless steel possesses an appealing aesthetic and can be finished in numerous manners to elevate its visual allure, thereby contributing to the stadium's overall design.

Send your message to us

Stainless Steel Sheet and Plate with good treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords