Stainless Steel 304 sheet and plate guarantee low price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

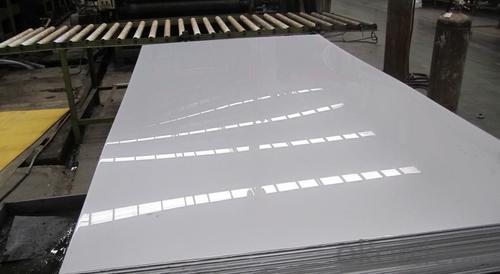

Specifications of stainless steel

304 stainless Steel Plate

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

TISCO stainless Steel Plate 304/NO.1 finished

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

Delivery short and low cost advantage.

Description of stainless steel:

stainless steel plate,hot rolled stainless steel plate,cold rolled stainless steel plate,stainless steel sheet,steel sheet,sheet

Material of stainless steel:

304,304L,309S,310S,316,316L,316Ti,317L,317L,321,347H,409,409L,410S,420,430,201,202,etc.

Thickness of stainless steel:

From 0.3mm to 100mm

Width of stainless steel:

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm,2500mm or as your requirement

Length of stainless steel:

2000mm,2438mm,2500mm,6000mm,6096mm or as your requirement

Application of stainless steel:

Stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Our company has cooperative relation between the domestic agents. Stainless steel plate can be made accordingto the customers requirements. Fasten delivery. Quality assured.Welcome to order more.

Contacts

If you have any question,please feel free to contact us.

- Q: What is the coefficient of expansion of stainless steel sheets?

- The coefficient of expansion of stainless steel sheets can vary depending on the specific grade or alloy of stainless steel being used. However, in general, stainless steel has a coefficient of expansion ranging from 10.8 to 16.3 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, stainless steel sheets will expand by approximately 10.8 to 16.3 millionths of their original length. It is important to note that different grades of stainless steel may have slightly different coefficients of expansion, so it is always recommended to consult the manufacturer or specific material specifications for accurate information.

- Q: Can stainless steel sheets be used for backsplashes?

- Yes, stainless steel sheets can be used for backsplashes.

- Q: How do I prevent galvanic corrosion on stainless steel sheets?

- To prevent galvanic corrosion on stainless steel sheets, there are several measures you can take: 1. Ensure proper alloy selection: Choose a grade of stainless steel that is less prone to galvanic corrosion. Grades such as 316 and 317 are more resistant to corrosion compared to 304 stainless steel. 2. Separate dissimilar metals: Avoid direct contact between stainless steel sheets and other metals, especially those with a higher potential for galvanic corrosion. If contact is necessary, use insulating materials such as gaskets or rubber pads to separate the metals. 3. Use protective coatings: Apply protective coatings or paints specifically designed for stainless steel to create a barrier and prevent galvanic corrosion. These coatings act as a sacrificial layer, shielding the stainless steel from direct contact with the corrosive material. 4. Use isolation materials: Install insulating materials between stainless steel sheets and other dissimilar metals. These can include plastic washers, insulating tape, or non-conductive gaskets to prevent direct electrical contact and subsequent corrosion. 5. Proper maintenance: Regularly clean and inspect stainless steel sheets to remove any contaminants or foreign substances that could promote corrosion. Avoid using abrasive cleaners or tools that could damage the protective layer of the stainless steel. 6. Electrochemical protection: Implement cathodic protection techniques, such as using sacrificial anodes or impressed current systems, to provide an external source of electrons that can counteract galvanic corrosion. These methods help shift the corrosion potential of the stainless steel sheets to a more passive range. By following these preventive measures, you can significantly reduce the risk of galvanic corrosion on stainless steel sheets, ensuring their longevity and maintaining their structural integrity.

- Q: How are stainless steel sheets finished?

- To achieve different appearances and textures, there are various ways to finish stainless steel sheets. The most common techniques for finishing stainless steel sheets are as follows: 1. Mill Finish: Stainless steel sheets have a dull, non-reflective surface with visible grain lines as a result of the manufacturing process. This is the standard finish when the sheets are first produced. 2. Brushed Finish: Also known as satin finish, this involves brushing the surface of the stainless steel with an abrasive material to create a consistent, fine grain appearance. It produces a smooth and matte finish, which is often preferred for aesthetic reasons. 3. Mirror Finish: This finish creates a highly reflective and mirror-like surface on the stainless steel sheets. It is achieved by progressively polishing the surface with finer abrasive materials until a smooth and reflective finish is achieved. 4. Embossed Finish: This technique involves impressing a pattern or design onto the surface of the stainless steel sheets. Heat and pressure are used to create raised or recessed patterns, adding texture and visual interest to the sheets. 5. Bead Blasted Finish: Fine glass beads or other abrasive materials are used to blast the surface of the stainless steel sheets. This creates a uniform, matte appearance with a slightly textured finish. 6. PVD Coating: Physical Vapor Deposition (PVD) is a process where a thin layer of metal or alloy is vaporized and deposited onto the surface of the stainless steel sheets. This coating enhances the appearance of the sheets, offering various colors and finishes such as gold, bronze, or black. In summary, the choice of finish for stainless steel sheets depends on the desired aesthetic, functionality, and application of the material. Each finish has its own unique characteristics, allowing for versatility and customization in various industries, including architecture, interior design, automotive, and more.

- Q: Can stainless steel sheets be used in the medical industry?

- Stainless steel sheets have the capability of being utilized within the medical industry. This is because stainless steel is a favored material within the medical field due to its exceptional resistance against corrosion, its remarkable strength, and its ability to endure. It is commonly employed for a diverse array of purposes, encompassing medical instruments, surgical tools, dental equipment, implants, and medical machinery. Moreover, stainless steel sheets are uncomplicated to cleanse and sterilize, rendering them perfect for maintaining hygienic conditions within medical settings. Furthermore, stainless steel is biocompatible, signifying that it is harmonious with human tissues and does not elicit any unfavorable reactions, thereby making it a secure option for medical applications. All in all, stainless steel sheets are exceedingly appropriate for usage within the medical industry due to their myriad advantageous qualities.

- Q: Can stainless steel sheets be used for elevator frames?

- Yes, stainless steel sheets can be used for elevator frames. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an ideal material for various applications, including elevator frames. The use of stainless steel sheets for elevator frames ensures a long-lasting and aesthetically pleasing structure that can withstand the wear and tear of everyday use. Additionally, stainless steel's sleek and modern appearance can enhance the overall design of the elevator, providing a sophisticated and stylish look.

- Q: What are the different shapes available for stainless steel sheets?

- Stainless steel sheets are available in various shapes, including flat sheets, perforated sheets, corrugated sheets, embossed sheets, and diamond plates. These shapes cater to different applications and aesthetic preferences in industries such as construction, automotive, and interior design.

- Q: What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- Austenitic stainless steel (non-magnetic) inside the 201 material is the cheapest, the average price of 9000 yuan / ton, including tax, accounting for 7.93 of the proportion of formula: thickness * width * length * weight = weight * unit price = per price

- Q: Are stainless steel sheets suitable for aerospace applications?

- Yes, stainless steel sheets are suitable for aerospace applications. Stainless steel is a versatile and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and high-temperature resistance, making it ideal for use in the aerospace industry. It is commonly used in the construction of aircraft structures, engine components, and fuel systems due to its ability to withstand extreme conditions and maintain structural integrity. Stainless steel sheets are also easy to form, weld, and fabricate, allowing for customization and precise engineering in aerospace applications. Additionally, stainless steel's resistance to fatigue and erosion makes it a reliable choice for aerospace components that are subject to constant stress and harsh environments. Overall, stainless steel sheets provide the necessary characteristics to meet the demanding requirements of the aerospace industry, making them a suitable choice for various applications.

- Q: Are stainless steel sheets good for industrial exhaust systems?

- Yes, stainless steel sheets are excellent for industrial exhaust systems. Stainless steel is known for its high resistance to corrosion, making it a highly durable and long-lasting material for exhaust systems. It can withstand high temperatures and extreme weather conditions, making it suitable for industrial environments. Stainless steel also has excellent strength and can handle the pressure and vibrations associated with exhaust systems. Additionally, stainless steel is easy to clean and maintain, which is important for keeping the exhaust system functioning efficiently. Overall, stainless steel sheets are a great choice for industrial exhaust systems due to their durability, corrosion resistance, and high temperature tolerance.

Send your message to us

Stainless Steel 304 sheet and plate guarantee low price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords