Stainless Steel Sheets 304 from China With Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

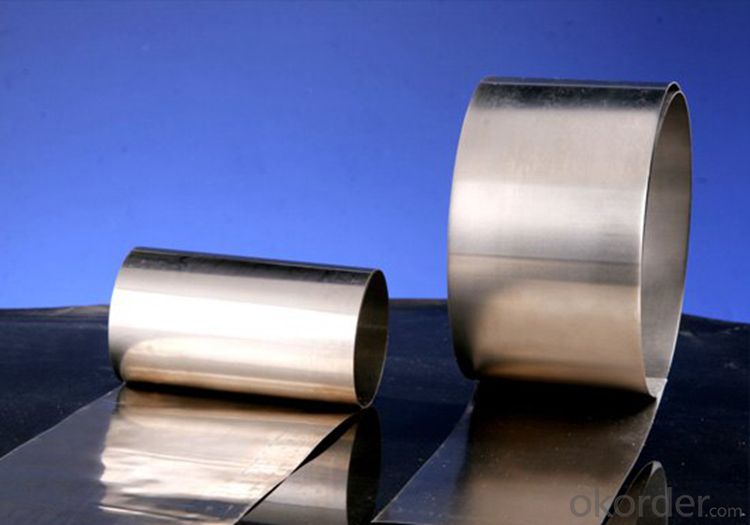

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

(1) Boiler heat exchanger,

(2) Chemical industries,

(3) Hardware fields,

(4) Construction material,

(5) Kitchen utensils,

(6) Building construction,

(7) Medical equipment,

(8) chemical tank,

(9) pipe etc

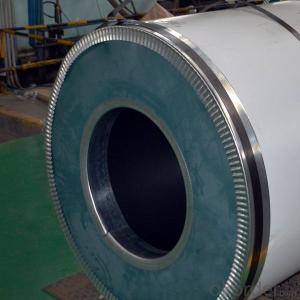

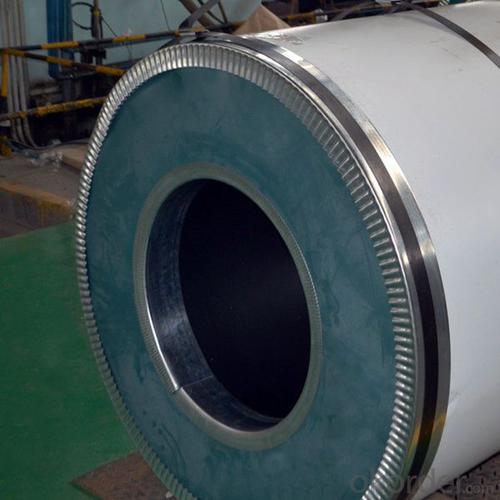

Detail picture for Stainless Steel

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be bent?

- Yes, stainless steel sheets can be bent. Stainless steel is a versatile material that can be easily formed into various shapes and configurations, including bends. The ability to bend stainless steel sheets is dependent on the thickness and composition of the material. Thinner sheets are generally more flexible and easier to bend, while thicker sheets may require specialized equipment and techniques. It is important to note that the bending process may cause the stainless steel sheet to lose some of its strength and durability, so careful consideration should be given to the specific application and requirements before attempting to bend stainless steel sheets.

- Q: How do you clean and maintain stainless steel sheets?

- To clean and maintain stainless steel sheets, you can start by wiping them down with a soft cloth or sponge dipped in warm, soapy water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. Rinse the sheets thoroughly and dry them with a clean cloth to prevent water spots. For regular maintenance, you can use a stainless steel cleaner or a mixture of equal parts water and vinegar to remove any fingerprints or smudges. Finally, remember to always wipe in the direction of the grain to maintain the steel's polished appearance.

- Q: Can stainless steel sheets be used for pharmaceutical equipment?

- Indeed, pharmaceutical equipment can utilize stainless steel sheets. Stainless steel is highly favored in the pharmaceutical industry due to its remarkable resistance to corrosion, durability, and ease of cleaning. It does not react with other substances and does not emit any detrimental substances that could compromise the quality or purity of pharmaceutical products. Stainless steel sheets can be molded into different forms and sizes to cater to the specific needs of pharmaceutical equipment, including storage tanks, mixing vessels, sterilization devices, and piping systems. Additionally, the sleek surface of stainless steel hinders the buildup of bacteria, rendering it an exceptionally sanitary option for pharmaceutical applications.

- Q: Are stainless steel sheets suitable for oil refineries?

- Yes, stainless steel sheets are suitable for oil refineries. Stainless steel is often chosen for its excellent resistance to corrosion, high temperature resistance, and durability. These properties make it highly suitable for the harsh conditions found in oil refineries, where the presence of corrosive chemicals, high temperatures, and constant exposure to moisture can be detrimental to other materials. Stainless steel sheets are commonly used in various applications within oil refineries, including storage tanks, pipelines, heat exchangers, and other equipment where corrosion resistance is crucial. Additionally, stainless steel sheets can be easily cleaned and maintained, which is important in maintaining the efficiency and functionality of equipment in oil refineries.

- Q: Can stainless steel sheets be used in medical applications?

- Yes, stainless steel sheets can be used in medical applications. Stainless steel is a popular choice in the medical field due to its excellent corrosion resistance, durability, and ease of sterilization. It is widely used in medical devices, surgical instruments, and implantable components due to its ability to withstand harsh sterilization processes such as autoclaving, which is crucial for maintaining cleanliness and preventing infections. Additionally, stainless steel is biocompatible, meaning it does not react with the body's tissues and does not cause any harm or adverse reactions. Overall, stainless steel sheets are a reliable and versatile material for various medical applications.

- Q: Are stainless steel sheets suitable for medical equipment?

- Yes, stainless steel sheets are suitable for medical equipment. Stainless steel is a popular choice for medical equipment due to its excellent corrosion resistance and durability. It is easy to clean and sterilize, making it suitable for use in healthcare settings where cleanliness and hygiene are crucial. Additionally, stainless steel has a high strength-to-weight ratio, allowing for the construction of lightweight yet sturdy medical equipment. It also has a low magnetic permeability, making it ideal for applications where electromagnetic interference needs to be minimized. Overall, stainless steel sheets are a reliable and practical choice for manufacturing medical equipment.

- Q: Are stainless steel sheets suitable for laboratory equipment or instruments?

- Yes, stainless steel sheets are highly suitable for laboratory equipment or instruments. Stainless steel is known for its excellent corrosion resistance, durability, and high strength, making it an ideal choice for laboratory applications. It is resistant to chemicals, heat, and staining, which ensures the longevity and reliability of the equipment. Additionally, stainless steel is easy to clean and maintain, meeting the strict hygiene standards required in laboratories.

- Q: Can stainless steel sheets be used for oil and gas pipelines?

- Yes, stainless steel sheets can be used for oil and gas pipelines. Stainless steel is commonly used in the oil and gas industry due to its excellent corrosion resistance properties. It can withstand the harsh conditions of transportation and storage of oil and gas, including high-pressure, high-temperature, and corrosive environments. Stainless steel sheets are often utilized to fabricate pipeline components such as pipes, fittings, and flanges, as they offer durability, strength, and resistance to corrosion, which helps to prevent leaks and maintain the integrity of the pipeline.

- Q: Can stainless steel sheets be used in high-pressure environments?

- High-pressure environments can certainly accommodate the use of stainless steel sheets. Renowned for remarkable strength and corrosion resistance, stainless steel proves itself fitting for tasks demanding high-pressure endurance. It remains intact and unyielding under immense pressure, never succumbing to deformation or fracture. Consequently, it emerges as an ideal choice for industries like oil and gas, chemical processing, and power generation, which frequently operate in high-pressure settings. Furthermore, stainless steel sheets retain their structural integrity and performance at elevated temperatures, bolstering their already impressive suitability for high-pressure situations.

- Q: Are stainless steel sheets resistant to sulfuric acid?

- Yes, stainless steel sheets are generally resistant to sulfuric acid.

Send your message to us

Stainless Steel Sheets 304 from China With Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords