Hot-Dip Galvanized Steel Coil with High Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 7000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

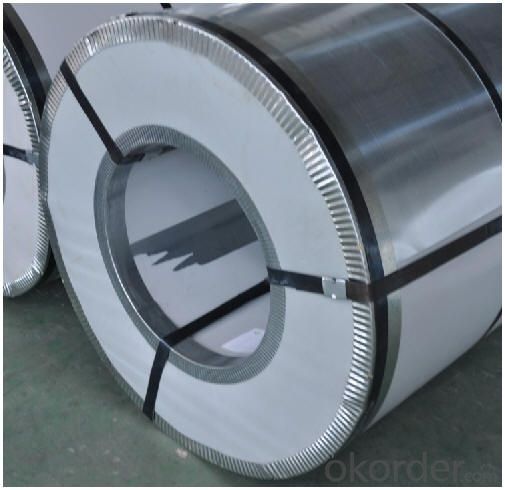

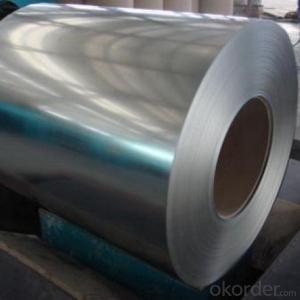

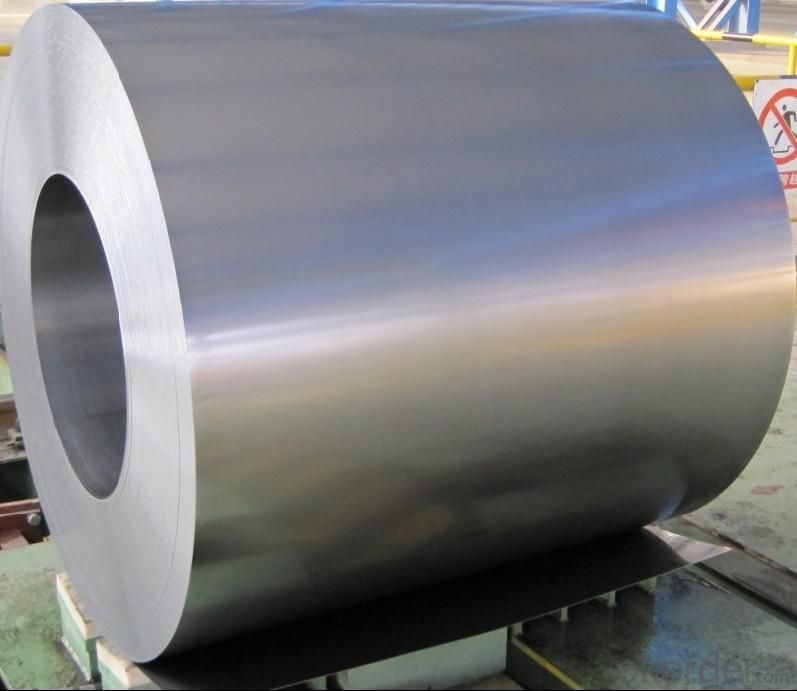

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

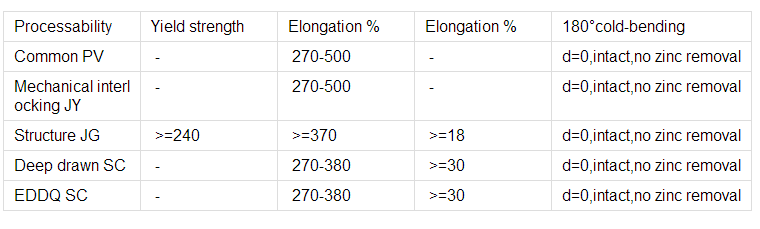

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: The difference between 304J1 stainless steel plate and 304 stainless steel plate

- 304J1 is a copper containing material of 304. It is mainly used in deep processing and also belongs to the series of nickel. By the Japanese on the basis of the successful development of American Standard 304.

- Q: Are stainless steel sheets suitable for roofing applications?

- Yes, stainless steel sheets are suitable for roofing applications. They are durable, corrosion-resistant, and provide excellent strength and longevity. Additionally, stainless steel sheets offer good aesthetic appeal and can withstand harsh weather conditions, making them a reliable choice for roofing projects.

- Q: What are the different types of stainless steel sheet surface coatings available?

- Different types of surface coatings are available for stainless steel sheets, each providing unique properties and advantages. Some of the most common types are: 1. Natural Finish: Stainless steel sheets without any coating have a smooth and natural surface. This type is commonly used when corrosion resistance is essential. 2. Brushed Coating: This coating creates a distinctive brushed pattern on the stainless steel surface. It adds a decorative touch while also concealing scratches and fingerprints. 3. Mirror Coating: A mirror finish coating gives stainless steel sheets a highly reflective surface, similar to a mirror. This type is popular in architectural and decorative applications. 4. Satin Coating: Satin coatings offer a smooth and matte appearance with low reflectivity. They are often used in high-end appliances and architectural elements. 5. Bead Blasted Coating: This coating creates a uniform and textured surface by bombarding the stainless steel with small glass beads. It provides a unique visual effect and can hide surface imperfections. 6. Patterned Coating: Patterned coatings involve embossing or etching designs onto the stainless steel surface. They can create various patterns and textures, enhancing the aesthetic appeal in different applications. 7. Colored Coatings: Stainless steel sheets can be coated with different colors using processes like powder coating or electroplating. This allows for customization and adds a decorative element to the material. When choosing a surface coating for stainless steel sheets, it is important to consider the specific requirements of your application. Factors such as corrosion resistance, durability, aesthetics, and functionality should all be taken into account to ensure the best choice for your needs.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Yes, stainless steel sheets can be used in the aerospace industry. Stainless steel is a versatile material that offers a high strength-to-weight ratio, corrosion resistance, and excellent mechanical properties, making it suitable for various aerospace applications. It is commonly used in the construction of aircraft components such as structural frames, engine parts, exhaust systems, and fuel tanks. Stainless steel sheets are also utilized in the production of aerospace fasteners, fittings, and interior cabin components. Its durability and resistance to temperature variations and extreme environments make it a reliable choice for the aerospace industry.

- Q: Can stainless steel sheets be used for wall paneling?

- Certainly! Wall paneling can be done using stainless steel sheets. Stainless steel is a versatile material that is famous for its durability, ability to resist corrosion, and attractive appearance. It is widely used in various applications, including wall paneling in both residential and commercial settings. Installing stainless steel sheets as wall panels is a breeze, giving the space a contemporary and elegant look. Moreover, stainless steel is effortless to clean and maintain, making it a practical choice for wall paneling in areas that require frequent cleaning, such as kitchens and bathrooms. In summary, stainless steel sheets are an excellent choice for wall paneling due to their long-lasting nature, aesthetic appeal, and ease of maintenance.

- Q: What are the properties of stainless steel sheets?

- Stainless steel sheets possess multiple properties that make them extremely desirable in various industries and applications. To begin with, their excellent corrosion resistance is a result of the presence of chromium in the alloy, which forms a protective oxide layer on the surface, preventing rust and staining. Moreover, stainless steel sheets are renowned for their strength and durability. They can withstand heavy loads and resist deformation due to their high tensile strength. This makes them suitable for applications requiring structural integrity and longevity, such as in construction, automotive, and aerospace sectors. Another significant property of stainless steel sheets is their resistance to heat and fire. They can endure high temperatures without losing their structural integrity or strength. As a result, they are ideal for applications involving extreme heat, like commercial kitchens and industrial furnaces. Additionally, stainless steel sheets are hygienic and easy to clean, making them suitable for use in the food and medical industries. Their non-porous surface prevents the growth of bacteria, making them a reliable choice for food processing equipment, surgical instruments, and medical devices. They also possess an attractive appearance, with a smooth, reflective surface that is easy to maintain. This makes them aesthetically pleasing and suitable for architectural and decorative applications, such as building facades, interior design, and furniture manufacturing. Lastly, stainless steel sheets are highly versatile and can be easily formed, welded, and fabricated into various shapes and sizes. This flexibility allows for customization and adaptation to specific project requirements, offering designers and engineers a wide range of possibilities. In summary, stainless steel sheets offer corrosion resistance, high strength and durability, heat and fire resistance, hygiene, ease of cleaning, an attractive appearance, and versatility. These properties have made them a popular choice in numerous industries, ensuring their widespread use in various applications.

- Q: Can stainless steel sheets be painted?

- Yes, stainless steel sheets can be painted. However, it is important to properly prepare the surface before painting to ensure good adhesion and longevity of the paint. The stainless steel surface should be cleaned and degreased thoroughly, and any existing rust or oxidation should be removed. A primer specifically formulated for use on metal surfaces should be applied to promote adhesion, followed by a high-quality paint designed for metal. It is also recommended to apply a clear coat or sealer to protect the paint finish. Keep in mind that regular maintenance may be required to maintain the appearance of the painted stainless steel sheets, as the paint may chip or wear over time.

- Q: Are stainless steel sheets resistant to scratches?

- Yes, stainless steel sheets are generally resistant to scratches. Stainless steel is known for its durability and strength, making it highly resistant to scratching or denting. However, it's important to note that no material is completely scratch-proof, and stainless steel can still develop minor scratches over time with regular use. However, these scratches are usually superficial and can often be easily removed or minimized with proper cleaning and maintenance. Additionally, the level of scratch resistance can vary depending on the grade and finish of the stainless steel sheet.

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets may differ based on their thickness and dimensions. Typically, stainless steel sheets possess a density of 8 grams per cubic centimeter. To determine the weight of a stainless steel sheet, one must acquire the dimensions (length, width, and thickness) and multiply them to ascertain the volume. Subsequently, the weight can be determined by multiplying the volume by the density.

- Q: What is the machinability of stainless steel sheets?

- The machinability of stainless steel sheets can vary depending on the grade of stainless steel and its specific composition. Generally, stainless steel is known to have lower machinability compared to other types of metals such as carbon steel or aluminum. This is mainly due to its higher strength, hardness, and work-hardening characteristics. Stainless steel has a tendency to work-harden during machining, leading to increased cutting forces and tool wear. It also has a lower thermal conductivity, which can result in higher temperatures during machining operations, further contributing to tool wear. Additionally, stainless steel has a unique chip formation behavior, often resulting in stringy and difficult-to-break chips. However, advancements in cutting tool technology and machining techniques have made it possible to improve the machinability of stainless steel. For instance, using appropriate cutting tool geometries, coatings, and coolant/lubricant can help reduce cutting forces, minimize tool wear, and improve chip control. It is important to note that different grades of stainless steel can exhibit varying machinability. Austenitic stainless steels, such as 304 and 316, are generally more difficult to machine compared to ferritic or martensitic stainless steels. This is due to their higher nickel and chromium content, which contribute to their superior corrosion resistance but also make them harder to machine. Overall, while stainless steel sheets may present some challenges in machining, with the right tools, techniques, and experience, it is possible to achieve satisfactory machinability and produce high-quality components from stainless steel sheets.

Send your message to us

Hot-Dip Galvanized Steel Coil with High Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 7000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords