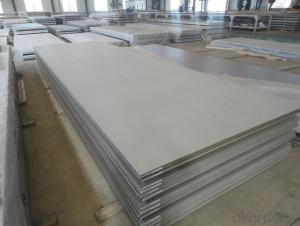

Stainless Steel Plate 304 with Small Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

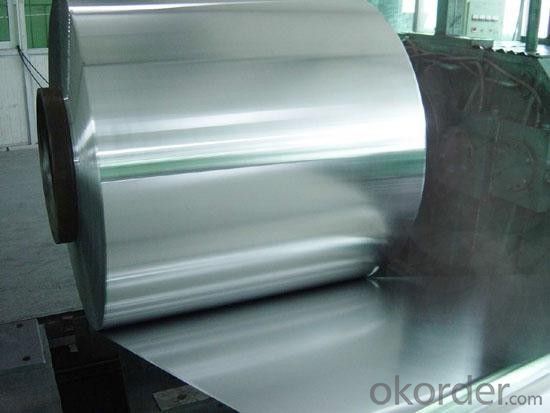

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for chemical storage vessels?

- Yes, stainless steel sheets are suitable for chemical storage vessels. Stainless steel is highly resistant to corrosion and can withstand harsh chemicals, making it a reliable choice for storing various types of chemicals safely.

- Q: Are stainless steel sheets suitable for laboratory equipment?

- Yes, stainless steel sheets are suitable for laboratory equipment. Stainless steel is highly resistant to corrosion, easy to clean, and has excellent strength and durability, making it ideal for use in laboratory settings where hygiene and durability are crucial.

- Q: Are stainless steel sheets suitable for elevator handrails?

- Elevator handrails can be made from stainless steel sheets, which are suitable due to their durability, resistance to corrosion, and attractive look. Handrails in elevators face constant use and exposure to various environmental factors, including moisture and fingerprints. However, stainless steel is highly resistant to corrosion, ensuring that the handrails last for a long time without the need for maintenance. Moreover, stainless steel has a sleek and modern appearance that complements the overall elevator design. Its smooth surface is easy to clean and maintain, making it a hygienic option for handrails in public areas. In summary, stainless steel sheets are an excellent choice of material for elevator handrails.

- Q: Can stainless steel sheets be used in construction projects?

- Yes, stainless steel sheets can be used in construction projects. Stainless steel is a versatile and durable material that is commonly used in various construction applications. It is known for its corrosion resistance, which makes it suitable for outdoor and high-moisture environments. Stainless steel sheets are often used for roofing, wall cladding, structural components, and decorative features in buildings. They can also be used for interior applications such as countertops, backsplashes, and elevator panels. Additionally, stainless steel sheets are available in various finishes and textures, allowing for customization and aesthetic appeal in construction projects.

- Q: Can stainless steel sheets be used in food processing industries?

- Yes, stainless steel sheets are commonly used in food processing industries for various applications. Stainless steel is highly resistant to corrosion, making it ideal for use in environments where food is processed, stored, or handled. It is hygienic, easy to clean, and does not react with the food, ensuring that the quality and safety of the food are maintained. Stainless steel sheets are used for making food preparation surfaces, worktables, countertops, sinks, shelves, storage tanks, and equipment like mixers, conveyors, and ovens. Additionally, stainless steel sheets are durable and can withstand high temperatures, making them suitable for a wide range of food processing operations.

- Q: What are the benefits of using textured stainless steel sheets in retail displays?

- Using textured stainless steel sheets in retail displays offers several benefits. Firstly, the textured surface adds a visually appealing and modern touch to the display, enhancing the overall aesthetics. Secondly, stainless steel is highly durable and resistant to corrosion, making it ideal for high-traffic retail environments. This ensures that the display will last longer and maintain its quality appearance. Additionally, stainless steel is easy to clean and maintain, saving time and effort for store employees. Lastly, the reflective nature of stainless steel sheets can help to create a more vibrant and eye-catching display, attracting customers and increasing the likelihood of sales.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Yes, stainless steel sheets are indeed suitable for heat transfer equipment. Stainless steel has excellent thermal conductivity, which allows for efficient heat transfer. It also has high corrosion resistance and can withstand high temperatures, making it a reliable choice for various heat transfer applications.

- Q: Are stainless steel sheets suitable for chemical processing plants?

- Chemical processing plants find stainless steel sheets highly suitable. The reason lies in the excellent corrosion resistance that stainless steel offers, making it the ideal choice for environments with chemicals. It can resist a wide range of chemicals, including acids, alkalis, and solvents, which are commonly present in chemical processing plants. Moreover, stainless steel sheets provide high strength and durability, enabling them to endure harsh operating conditions and maintain their structural integrity over time. They are also easy to clean and maintain, ensuring a hygienic environment in chemical processing plants. Furthermore, stainless steel sheets possess favorable thermal properties, making them appropriate for applications involving extreme temperatures. Additionally, they have low magnetic permeability, which proves advantageous in certain chemical processing operations. All in all, stainless steel sheets are a favored option in chemical processing plants due to their corrosion resistance, strength, durability, and ease of maintenance.

- Q: Can stainless steel sheets be used for cryogenic applications?

- Indeed, cryogenic applications can utilize stainless steel sheets. Stainless steel boasts remarkable mechanical properties, corrosion resistance, and low thermal conductivity, rendering it fitting for cryogenic settings. It endures frigid temperatures without succumbing to brittleness or weakening. Frequently, stainless steel sheets find employment in cryogenic applications like storage tanks, piping systems, and cryogenic equipment. Nevertheless, it is crucial to select the proper grade of stainless steel, specifically intended for cryogenic applications, to guarantee utmost performance and durability.

- Q: What are the different types of punched finishes available for stainless steel sheets?

- Stainless steel sheets offer a range of punched finishes, each with distinct qualities and advantages. Let's explore some of the most commonly used options: 1. Round Hole: This punched finish, which features evenly spaced round holes, is highly versatile and widely utilized. It enables effective airflow and visibility and finds applications in ventilation systems, decorative panels, and filters. 2. Square Hole: With a clean and contemporary appearance, the square hole punched finish is often chosen when a more geometric pattern is desired. It is commonly employed in architectural projects, screens, and fencing. 3. Slotted Hole: The slotted hole punched finish is characterized by elongated holes, providing larger openings for enhanced visibility or improved drainage. It finds uses in grilles, sunshades, and safety barriers. 4. Hexagonal Hole: Offering an aesthetically pleasing pattern, the hexagonal hole punched finish showcases hexagon-shaped holes. It is commonly used in decorative applications like wall cladding, signage, and artistic installations. 5. Decorative Patterns: In addition to the standard punched finishes, stainless steel sheets can be customized with various decorative patterns, including personalized designs, logos, or intricate shapes. This allows for a unique and personalized touch in any project. When choosing a punched finish for stainless steel sheets, it is crucial to consider the specific requirements of the application, including aesthetics, functionality, and performance. Key factors to consider include hole size, open area percentage, strength, and corrosion resistance.

Send your message to us

Stainless Steel Plate 304 with Small Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords