Stainless Steel Sheet 430 with Small Moq #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

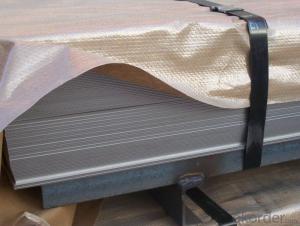

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets resistant to chlorine?

- Stainless steel sheets possess a general resistance to chlorine, as they are renowned for their corrosion-resistant properties. They are capable of enduring exposure to chlorine without experiencing substantial degradation. Hence, stainless steel sheets prove to be an appropriate option for implementing in environments containing chlorine, such as swimming pools, water treatment plants, and chemical processing facilities. Nevertheless, it is crucial to acknowledge that extended exposure to high concentrations of chlorine or specific chemicals can still induce corrosion or discoloration on the surfaces of stainless steel. To maintain the longevity and aesthetic appeal of stainless steel sheets in chlorinated settings, regular maintenance and adherence to proper cleaning procedures are imperative.

- Q: How are stainless steel sheets produced?

- Stainless steel sheets are produced through a series of manufacturing processes that involve various stages. The production of stainless steel sheets typically begins by melting raw materials such as iron ore, coal, and limestone in a blast furnace. This process is known as primary steelmaking and results in the production of molten iron. The molten iron is then transferred to a basic oxygen furnace (BOF) or electric arc furnace (EAF) where it is mixed with scrap steel and other alloys to adjust the desired chemical composition. The molten mixture undergoes a refining process to remove impurities and achieve the desired quality of stainless steel. Once the refining process is complete, the molten stainless steel is cast into slabs or billets. These large blocks of solidified metal are then heated and rolled into thin sheets through a process called hot rolling. Hot rolling involves passing the stainless steel through a series of rollers to reduce its thickness and shape it into the desired dimensions. After hot rolling, the stainless steel sheets undergo a process known as annealing. This process involves heating the sheets to a specific temperature and allowing them to cool slowly. Annealing helps to relieve internal stresses and improve the material's mechanical properties, such as strength and ductility. Following annealing, the stainless steel sheets may undergo further processing such as cold rolling, which involves passing the sheets through a series of rollers at room temperature to achieve the desired thickness and surface finish. Cold rolling also enhances the stainless steel's mechanical properties and improves its surface quality. Once the sheets have been cold rolled, they are typically coated with a protective film or passivation layer to prevent corrosion. This film acts as a barrier against environmental factors and helps maintain the longevity of the stainless steel sheets. Finally, the stainless steel sheets are cut into the desired sizes and shapes using various cutting techniques such as shearing or laser cutting. The sheets may undergo additional surface treatments, such as polishing or brushing, to achieve the desired aesthetic appearance. In summary, stainless steel sheets are produced by melting raw materials, refining the molten metal, casting it into slabs, hot rolling to reduce thickness, annealing to improve properties, cold rolling for further refinement, coating for corrosion resistance, and finally cutting and surface treatment to achieve the desired product.

- Q: How do I prevent galling on stainless steel sheets?

- To avoid galling on stainless steel sheets, there are various actions that can be taken: 1. Use lubrication: Apply a suitable lubricant to the stainless steel sheets, particularly in areas where they come into contact with other surfaces or materials. This will decrease friction and help prevent galling. 2. Avoid similar metals: Galling can occur when stainless steel sheets come into contact with other stainless steel surfaces due to the transfer of metal particles. To prevent this, try using different metals or non-metallic materials that are compatible with stainless steel. 3. Improve surface finish: Ensure that the stainless steel sheets have a smooth surface finish. Rough surfaces can increase friction and the likelihood of galling. Consider utilizing polishing or grinding techniques to achieve a smoother surface. 4. Control contact pressure: Excessive pressure between stainless steel sheets can lead to galling. Minimize contact pressure by adjusting clamping forces or utilizing gaskets, washers, or other materials that distribute the load evenly. 5. Reduce sliding speed: High sliding speeds can contribute to galling. Slow down the movement or apply anti-galling coatings to decrease the risk of galling on stainless steel sheets. 6. Perform regular maintenance: Regularly inspect the stainless steel sheets for signs of wear or damage. Address any issues promptly to prevent further damage that could result in galling. By implementing these preventive measures, the occurrence of galling on stainless steel sheets can be significantly reduced, ensuring their longevity and optimal performance.

- Q: Are stainless steel sheets resistant to intergranular corrosion?

- Yes, stainless steel sheets are generally resistant to intergranular corrosion due to the presence of chromium in their alloy composition. Chromium forms a protective oxide layer on the surface of stainless steel, preventing corrosive substances from penetrating the material and causing intergranular corrosion.

- Q: How many steps do I need for stamping the stainless steel plate?

- Stamping molding (Stamping forming), is on press and die force on plate, strip, pipe and profiles, the plastic deformation or separation, thus obtaining the required shape and size of the workpiece (stamping molding method). Stamping billets are mainly hot-rolled and cold-rolled steel plates and steel strips.

- Q: Can stainless steel sheets be used for bridge construction?

- Certainly, bridge construction can make use of stainless steel sheets. Given its exceptional durability and resistance to corrosion, stainless steel emerges as an ideal option when confronted with harsh environmental conditions. The structural strength, stability, and long-term dependability offered by stainless steel sheets render them suitable for a myriad of bridge components, including beams, girders, and decking. Moreover, stainless steel's aesthetic charm and minimal maintenance demands further enhance its appropriateness for bridge construction endeavors.

- Q: What's the difference between cold rolling and hot rolling of stainless steel plate?

- Cold rolling and hot rolling are different processes, and cold rolling is usually made by longitudinal rolling. Cold rolling process usually includes preparation of raw materials, pickling, rolling, degreasing, annealing (heat treatment), finishing and so on. Cold rolling takes hot rolling product as raw material, and the raw material should be removed before cold rolling so as to ensure the surface cleanness of cold rolling products.

- Q: When milling the stainless steel plate, how can he deform?

- Our company has many special parts for stainless steel processing, the following are our experiences:1., processing stainless steel, when processing, do not stop pouring cutting fluid, to prevent thermal deformation

- Q: What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- Ferritic stainless steel (with magnetic) inside 409 minimum, average price of 7800 yuan / ton, including tax, the proportion of 7.75, the formula is the same as above

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets may differ based on their thickness and dimensions. Typically, stainless steel sheets possess a density of 8 grams per cubic centimeter. To determine the weight of a stainless steel sheet, one must acquire the dimensions (length, width, and thickness) and multiply them to ascertain the volume. Subsequently, the weight can be determined by multiplying the volume by the density.

Send your message to us

Stainless Steel Sheet 430 with Small Moq #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords