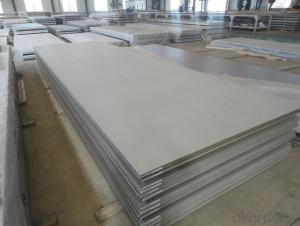

Stainless Steel Plate 304 with Standard Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

How are we supplying now?

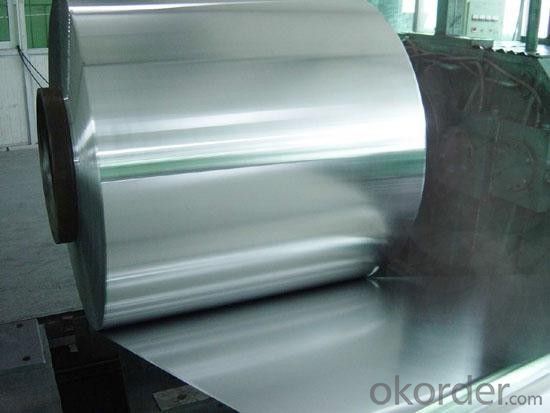

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be bent?

- Yes, stainless steel sheets can be bent. Stainless steel is a versatile material that can be easily formed into various shapes and configurations, including bends. The ability to bend stainless steel sheets is dependent on the thickness and composition of the material. Thinner sheets are generally more flexible and easier to bend, while thicker sheets may require specialized equipment and techniques. It is important to note that the bending process may cause the stainless steel sheet to lose some of its strength and durability, so careful consideration should be given to the specific application and requirements before attempting to bend stainless steel sheets.

- Q: What is the composition of stainless steel sheets?

- Stainless steel sheets are primarily composed of iron, chromium, and nickel, with varying levels of carbon and other elements depending on the specific grade or alloy.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets typically ranges from 1500°F to 1650°F (815°C to 900°C), depending on the grade of stainless steel.

- Q: What are the different types of stainless steel sheet finishes for medical applications?

- There are several different types of stainless steel sheet finishes that are commonly used for medical applications. These finishes are designed to provide specific qualities and characteristics that are necessary for medical environments. One common finish is the 2B finish, which is a smooth, reflective finish that is achieved through a cold-rolling process. This finish is often used in medical equipment and instruments as it is easy to clean and has a high corrosion resistance. Another commonly used finish is the No. 4 finish, also known as a satin finish. This finish has a brushed appearance and is often used in medical cabinets and surfaces. It provides a good combination of aesthetics and functionality, as it is easy to clean and has good corrosion resistance. For more specialized applications, there are also finishes such as the No. 8 mirror finish. This finish is highly reflective and is often used in surgical instruments and other high-end medical equipment. It provides a visually appealing surface and has excellent corrosion resistance. In addition to these finishes, there are also other options such as the bead blast finish, which creates a matte surface with a textured appearance. This finish is often used for medical equipment that requires a non-reflective surface. Overall, the choice of stainless steel sheet finish for medical applications depends on the specific requirements of the equipment or surface. Each finish has its own advantages and characteristics, and it is important to select the appropriate finish to ensure the best performance and longevity in a medical environment.

- Q: Can stainless steel sheets be used for elevator buttons?

- Yes, stainless steel sheets can be used for elevator buttons. Stainless steel is often chosen for its durability, resistance to corrosion, and sleek appearance, making it a suitable material for elevator buttons that are frequently touched and exposed to various environmental conditions.

- Q: Can stainless steel sheets be used for chemical storage tanks?

- Yes, stainless steel sheets can be used for chemical storage tanks. Stainless steel is known for its corrosion resistance, making it an ideal choice for storing a wide range of chemicals. It is durable, easy to clean, and can withstand high temperatures and pressure, making it a reliable material for chemical storage applications.

- Q: What stainless steel can be used instead of galvanized sheet?

- Galvanized sheet can be replaced by 201 stainless steel.

- Q: What are the applications of stainless steel sheets in the construction industry?

- Stainless steel sheets have various applications in the construction industry due to their unique properties. They are often used for cladding buildings, roofing, and wall systems, providing durability and resistance to corrosion. Additionally, stainless steel sheets are used for structural components such as beams, columns, and reinforcement bars, ensuring strength and longevity in construction projects. They are also utilized in decorative applications, such as handrails, facades, and interior design elements, enhancing the aesthetic appeal of buildings. Overall, stainless steel sheets play a crucial role in the construction industry by offering both functional and aesthetic benefits.

- Q: How do you prevent scratches or dents on stainless steel sheets?

- To prevent scratches or dents on stainless steel sheets, there are a few measures you can take: 1. Handle with care: When handling stainless steel sheets, be cautious to avoid dropping or dragging them against rough surfaces. Use gloves or protective gear to minimize the risk of scratches caused by sharp objects or tools. 2. Clean with soft materials: To prevent scratches during cleaning, use soft cloths or non-abrasive sponges. Avoid using steel wool or harsh cleaning agents that can damage the surface. Additionally, always wipe in the direction of the grain to maintain the stainless steel's appearance. 3. Use protective films or sheets: Applying a protective film or sheet to the stainless steel surface can provide an extra barrier against scratches or dents. These films are typically adhesive and can be easily removed once the stainless steel sheets are installed. 4. Store properly: Store stainless steel sheets in a clean and dry environment to prevent scratches or dents caused by contact with other objects. Avoid stacking sheets directly on top of each other without any protective barrier in between. 5. Invest in edge protectors: Stainless steel sheets are often susceptible to dents or scratches on their edges. Using edge protectors or corner guards can help prevent damage during handling, transportation, or storage. By following these preventive measures, you can significantly reduce the chances of scratches or dents on stainless steel sheets, ensuring their longevity and maintaining their pristine appearance.

- Q: Can stainless steel sheets be used in outdoor applications?

- Certainly, outdoor applications can indeed make use of stainless steel sheets. Stainless steel, known for its exceptional resistance against corrosion and oxidation, proves to be a perfect option for outdoor purposes. It can endure challenging weather conditions, encompassing rainfall, snowfall, and even UV radiation, without undergoing rust or deterioration. Moreover, stainless steel exhibits impressive durability, allowing it to withstand heavy burdens and impacts, rendering it appropriate for a multitude of outdoor applications such as cladding, roofing, fencing, and decorative elements. Its attractiveness in terms of aesthetics and minimal upkeep needs further contribute to its popularity in outdoor usage.

Send your message to us

Stainless Steel Plate 304 with Standard Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords