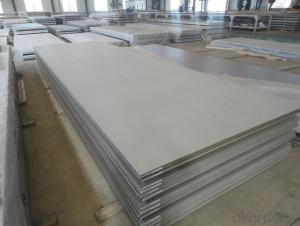

Stainless Steel Plate 304 with Normal Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

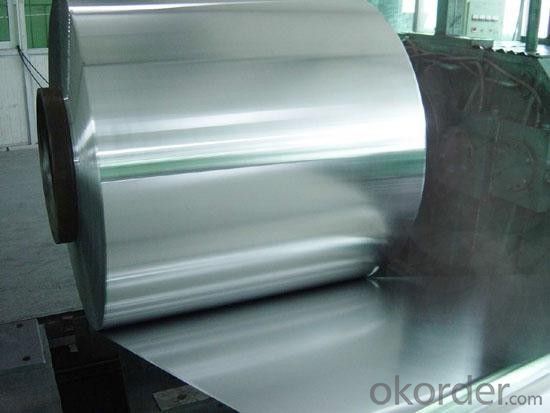

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the common sizes of stainless steel sheets?

- The common sizes of stainless steel sheets vary, but some common dimensions include 4 feet by 8 feet, 5 feet by 10 feet, and 4 feet by 12 feet.

- Q: Are stainless steel sheets suitable for chemical transport containers?

- Yes, stainless steel sheets are suitable for chemical transport containers. Stainless steel is known for its excellent corrosion resistance, which makes it highly suitable for transporting chemicals. It is resistant to many acids, alkalis, and corrosive substances, ensuring that the chemicals being transported are not compromised or contaminated during transit. Additionally, stainless steel sheets are also durable and strong, providing structural integrity to the containers and ensuring the safe transportation of chemicals.

- Q: Are stainless steel sheets suitable for fire-rated applications?

- Yes, stainless steel sheets are suitable for fire-rated applications. Stainless steel is known for its high resistance to heat and fire, making it a reliable choice for fire-rated applications. It has a high melting point and does not easily deform or lose its structural integrity when exposed to high temperatures. Additionally, stainless steel does not combust or release toxic fumes when heated, which is crucial in fire-rated applications where safety is a top priority. Stainless steel sheets are commonly used in fire-resistant doors, walls, and other structural components to enhance fire resistance and protect against the spread of flames.

- Q: Can stainless steel sheets be used for outdoor signage?

- Indeed, outdoor signage can be made using stainless steel sheets. This material, known for its durability and resistance to corrosion, remains unscathed in challenging weather conditions while preserving its visual appeal. Its widespread use in outdoor signage can be attributed to its ability to withstand rust, fading, and harm caused by sunlight, rain, snow, and other environmental factors. Moreover, stainless steel sheets can be personalized with different finishes like brushed or polished, enhancing their aesthetic allure and making them suitable for any outdoor signage requirement.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- There are several measures that can be taken to prevent pitting or crevice corrosion on stainless steel sheets: 1. It is crucial to choose the right grade of stainless steel, as grades with higher levels of chromium, molybdenum, and nickel provide better resistance to corrosion. 2. Ensuring a smooth and clean surface is essential. Corrosion can be initiated by rough surfaces or scratches. Creating a smoother surface can be achieved by polishing or electropolishing the stainless steel sheets. 3. Regular cleaning using mild detergents and non-abrasive cleaners is important to remove contaminants that may corrode the stainless steel sheets. It is also necessary to avoid using chlorine-based cleaners or abrasive materials that can damage the protective oxide layer. 4. Pitting and crevice corrosion are intensified in stagnant environments, so proper drainage and avoiding the accumulation of stagnant water or debris can help prevent this type of corrosion. 5. Stainless steel sheets should be protected from exposure to aggressive chemicals, such as chloride-containing solutions or acidic substances. Additionally, proper ventilation and humidity control can help reduce the risk of corrosion. 6. Applying protective coatings, such as paints or passivation treatments, can provide an additional layer of protection against pitting and crevice corrosion. 7. Regular inspections should be conducted to detect any signs of corrosion early on. Prompt remedial actions, such as repairing damaged coatings or addressing any drainage issues, can prevent the spread of corrosion. By following these preventive measures, the risk of pitting or crevice corrosion on stainless steel sheets can be significantly reduced, ensuring their longevity and maintaining their aesthetic appeal.

- Q: Can stainless steel sheets be used for kitchen countertops?

- Yes, stainless steel sheets can be used for kitchen countertops. Stainless steel is a durable and hygienic material that is resistant to stains, heat, and bacteria. It is a popular choice for kitchen countertops due to its modern aesthetic, easy maintenance, and ability to withstand heavy use.

- Q: What is the electrical conductivity of stainless steel sheets?

- The electrical conductivity of stainless steel sheets can vary depending on the specific grade and composition of the stainless steel. Generally, stainless steel is not known for its high electrical conductivity compared to other metals such as copper or aluminum. However, it still possesses some level of electrical conductivity. The electrical conductivity of stainless steel is typically lower than that of most metals because it contains a higher proportion of non-conductive elements such as chromium and nickel. Stainless steel is often chosen for its corrosion resistance rather than its electrical conductivity. However, it can still be used in certain electrical applications where moderate conductivity is acceptable.

- Q: Can stainless steel sheets be used in high-pressure environments?

- Yes, stainless steel sheets can be used in high-pressure environments. Stainless steel is known for its excellent strength, durability, and corrosion resistance, making it suitable for applications that require withstanding high pressure conditions. The material's ability to resist deformation and maintain its integrity under extreme pressure makes it a preferred choice in industries such as oil and gas, chemical processing, and aerospace.

- Q: Are stainless steel sheets suitable for medical applications?

- Yes, stainless steel sheets are suitable for medical applications. Stainless steel is a commonly used material in the medical industry due to its excellent corrosion resistance, durability, and ease of sterilization. It is utilized in various medical instruments, implants, surgical tools, and equipment where hygiene and biocompatibility are essential requirements.

- Q: Are stainless steel sheets suitable for cryogenic storage containers?

- Indeed, cryogenic storage containers are well-suited for stainless steel sheets. Renowned for its outstanding qualities at low temperatures, stainless steel proves to be an optimal option for cryogenic purposes. Its remarkable resistance to thermal expansion and contraction minimizes the risk of cracking or leaking even in extremely low temperatures. Moreover, stainless steel boasts exceptional durability and corrosion resistance, enabling it to endure the harsh conditions of cryogenic storage and guarantee the safety and integrity of stored materials. Consequently, stainless steel sheets find extensive application in the creation of cryogenic storage containers across diverse industries, including pharmaceuticals, aerospace, and scientific research.

Send your message to us

Stainless Steel Plate 304 with Normal Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords