Stainless Steel Plate 430 with Small Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

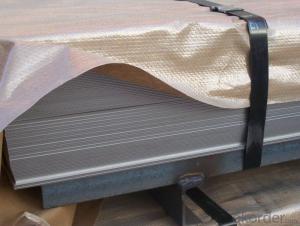

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the flatness tolerance for stainless steel sheets?

- The flatness tolerance for stainless steel sheets typically falls within the range of 0.25-0.50% of the sheet thickness.

- Q: Are stainless steel sheets suitable for dairy processing equipment?

- Yes, stainless steel sheets are highly suitable for dairy processing equipment. Stainless steel is known for its corrosion resistance, durability, and hygiene properties, making it an ideal material for equipment used in the dairy industry. It is easy to clean, resistant to bacterial growth, and does not react with dairy products, ensuring the safety and quality of the processed food.

- Q: 1cm thick 201 stainless steel plate how much money party

- Water or other weak corrosive medium or stainless steel is called stainless steel; and chemical resistance medium (acid, alkali, salt and other chemical etching) corrosion of steel is called acid resistant steel. Because of the difference in the chemical composition of the two, and make their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical medium corrosion, and acid resistant steel are generally stainless steel.

- Q: How high is the temperature of 2520 stainless steel?

- 310S is a good oxidation resistance, corrosion resistance, high temperature resistance, because the higher percentage of chromium and nickel, 310S has better creep strength, can continuously work under high temperature, good heat resistance. If the pure heat is not more than 1300 is OK, but if want to heat processing the rolling deformation cannot exceed this temperature, the heating time is not short not long

- Q: Can stainless steel sheets be used for architectural railings?

- Yes, stainless steel sheets can be used for architectural railings. Stainless steel is a popular material choice for architectural railings due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel sheets can be custom fabricated and shaped into various designs and sizes to meet the specific requirements of the architectural railing project. Additionally, stainless steel sheets can be finished in different ways, such as brushed, polished, or textured, to achieve the desired look and feel. Overall, stainless steel sheets are a versatile and reliable choice for architectural railings, providing both functionality and visual appeal.

- Q: How do you remove stains or marks from stainless steel sheets?

- To remove stains or marks from stainless steel sheets, you can start by wiping the surface with a soft cloth or sponge dipped in a mixture of warm water and mild dish soap. Gently scrub the affected area in the direction of the grain, then rinse with clean water and dry thoroughly. For tougher stains, you can apply a paste of baking soda and water, leave it on for a few minutes, and then scrub gently before rinsing and drying. Avoid using abrasive cleaners or scrub brushes that can scratch the stainless steel surface.

- Q: What is the difference between hot rolled and cold rolled stainless steel sheets?

- Hot rolled and cold rolled stainless steel sheets differ in their manufacturing process, resulting in distinctive characteristics and properties. Hot rolled stainless steel sheets are manufactured by passing the stainless steel through a series of rollers at a high temperature. This process results in a thicker and rougher surface compared to cold rolled sheets. Hot rolling allows for faster production and is generally more cost-effective. However, the rougher surface may require additional processing, such as grinding or polishing, to achieve the desired finish. On the other hand, cold rolled stainless steel sheets are manufactured by cooling the hot rolled sheets and then annealing them in a controlled environment. This process improves the surface finish, resulting in a smoother and more uniform appearance. Cold rolling also allows for tighter tolerances and greater strength, making it suitable for applications that require precise dimensions and superior mechanical properties. In terms of strength and hardness, cold rolled stainless steel sheets generally exhibit greater strength and hardness compared to hot rolled sheets. This is due to the strain hardening that occurs during the cold rolling process. Cold rolled sheets are also less susceptible to deformation and warping, making them ideal for applications where flatness is critical. In summary, the main differences between hot rolled and cold rolled stainless steel sheets lie in their manufacturing process, surface finish, dimensional tolerance, and mechanical properties. Hot rolled sheets are thicker and have a rougher surface, while cold rolled sheets are thinner, smoother, and exhibit greater strength and hardness. The choice between the two depends on the specific requirements of the application and the desired aesthetic and functional characteristics.

- Q: What is the maximum width available for stainless steel sheets?

- The maximum width available for stainless steel sheets can vary depending on the manufacturer and specific product, but it typically ranges from 48 inches to 72 inches.

- Q: What are the common grades of stainless steel sheets used in construction?

- Stainless steel sheets used in construction are typically classified into three common grades: austenitic, ferritic, and duplex stainless steels. The most widely used grades are austenitic stainless steels, including 304 and 316, which are known for their excellent corrosion resistance and high strength. These grades are commonly applied in architectural applications, roofing, cladding, and structural components. On the other hand, ferritic stainless steels, represented by 430, possess good corrosion resistance and high toughness, making them suitable for applications that prioritize strength and durability. They are often utilized for decorative purposes, interior design elements, and automotive trim. Meanwhile, duplex stainless steels like 2205 offer a combination of outstanding corrosion resistance and high strength, making them ideal for heavy-duty construction applications. These grades are frequently used in bridges, offshore structures, and industrial plants where superior strength and resistance to chloride-induced stress corrosion cracking are necessary. It should be emphasized that the choice of stainless steel sheet grade depends on the specific requirements of the construction project, including the environment, load-bearing capacity, and aesthetic considerations. Seeking advice from a materials engineer or a stainless steel supplier can help determine the most suitable grade for a particular construction application.

- Q: What is the minimum thickness available for stainless steel sheets?

- The minimum thickness of stainless steel sheets can differ depending on the grade and manufacturer. Nevertheless, typically stainless steel sheets are readily obtainable in thicknesses that span from 0.4mm to 6mm. Certain manufacturers might even offer thinner sheets, like 0.3mm, for particular applications. To ascertain the precise minimum thickness that suits your specific needs, it is crucial to consult with the supplier or manufacturer.

Send your message to us

Stainless Steel Plate 430 with Small Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords