Stainless Steel Coils 400 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

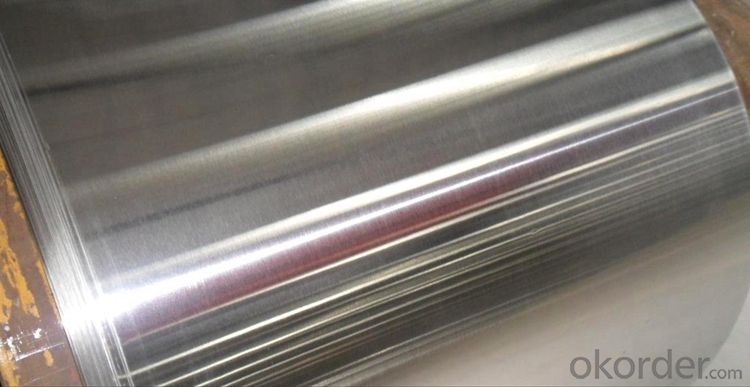

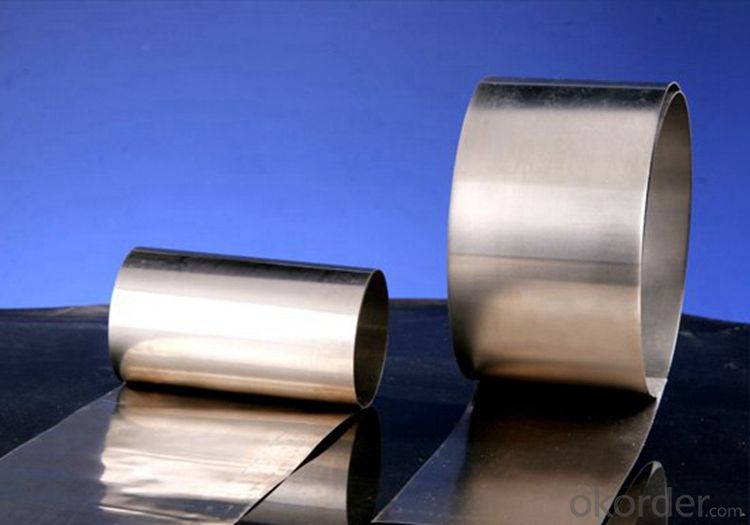

Detail picture for Stainless Steel Coils/Sheets

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- If you want to scrub the proposal as soon as possible processing, water Jiyue long more difficult to wear off, if it is ferrite, also easy to rust.

- Q: What is the corrosion resistance of stainless steel sheets in saltwater?

- Stainless steel sheets have excellent corrosion resistance in saltwater environments. The high levels of chromium present in stainless steel enable the formation of a passive oxide layer on the surface, which acts as a protective barrier against corrosion. This oxide layer is highly resistant to saltwater, preventing the metal from being directly exposed to the corrosive effects of the saltwater. Additionally, stainless steel alloys such as 316 and 316L contain molybdenum, which further enhances their resistance to pitting and crevice corrosion in saltwater. Overall, stainless steel sheets are a preferred choice for applications in saltwater environments due to their exceptional corrosion resistance properties.

- Q: Can stainless steel sheets be used in food processing or medical applications?

- Yes, stainless steel sheets can be used in food processing and medical applications. Stainless steel is highly resistant to corrosion and is easy to clean, making it suitable for use in environments that require strict hygiene standards such as food processing plants and medical facilities. It is also non-reactive with food and medical substances, ensuring the safety and quality of the products being processed or treated.

- Q: Are stainless steel sheets suitable for cryogenic storage tanks?

- Indeed, cryogenic storage tanks can utilize stainless steel sheets. Renowned for its outstanding corrosion resistance, stainless steel proves to be highly compatible with the storage of substances such as liquefied natural gas (LNG), liquid nitrogen, or liquid oxygen, which demand low-temperature environments. These tanks necessitate materials capable of enduring exceedingly frigid temperatures without succumbing to brittleness or compromising their strength, and stainless steel successfully fulfills these criteria. Furthermore, stainless steel boasts commendable thermal conductivity, facilitating the maintenance of the desired temperature within the tank. Its ease of cleaning and maintenance further cements its status as the preferred choice for cryogenic storage tanks across diverse industries.

- Q: What are the different types of stainless steel sheet thickness tolerances?

- The different types of stainless steel sheet thickness tolerances include standard, tight, and extra tight tolerances. Standard tolerances allow for slight variations in thickness, tight tolerances have lower permissible deviations, and extra tight tolerances have even smaller allowable variations in thickness.

- Q: Can stainless steel sheets be used for magnetic shielding?

- Yes, stainless steel sheets can be used for magnetic shielding. Stainless steel has a high permeability, which means it can redirect and absorb magnetic fields, making it an effective material for shielding against magnetic interference.

- Q: What drill can drill stainless steel?

- Cobalt bit, hard alloy drill bit, can drill stainless steel.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it suitable for storing various items. It also has a high load-bearing capacity, making it ideal for heavy-duty storage applications.

- Q: What's the difference between stainless steel 304 2B board and Ba board?

- BA 2B process is not the same, finished products are not the same.The BA plate is rolled with a work roll of roughness 0.006-0.008 and annealed in a vertical furnace. The surface is very mirror like;2B edge Miao made by using roughness of work rolls 0.2-0.28, commonly used in horizontal continuous annealing production, rough surface.

- Q: Can stainless steel sheets be used for medical implant devices?

- Medical implant devices can utilize stainless steel sheets, as they possess excellent mechanical properties, corrosion resistance, and biocompatibility. Stainless steel is widely employed in the medical field due to its strength, durability, and ability to endure sterilization processes. Various medical implant devices, including plates, screws, and pins used in orthopedic surgeries, dental implants, cardiovascular devices, and other procedures, can be fabricated from stainless steel sheets. The high strength-to-weight ratio of stainless steel makes it suitable for applications requiring load-bearing capabilities, while its resistance to corrosion ensures longevity within the body. Moreover, stainless steel is a biocompatible material, meaning it is well-tolerated by the human body and does not cause adverse reactions or allergies. Techniques like passivation or coating can enhance the biocompatibility of stainless steel surfaces. It is vital to emphasize that selecting the appropriate stainless steel grade and surface finish is essential for medical implant devices to ensure compatibility with specific body tissues and environments. Thorough testing and regulatory approval are also necessary to guarantee the safety and effectiveness of stainless steel medical implant devices. To summarize, stainless steel sheets can indeed be utilized for medical implant devices due to their mechanical properties, corrosion resistance, and biocompatibility. Ensuring the suitability and safety of stainless steel implants in medical applications necessitates proper selection, testing, and regulatory approval.

Send your message to us

Stainless Steel Coils 400 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords