Steel Coils 200 Series Steel Plate Steel Sheets Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

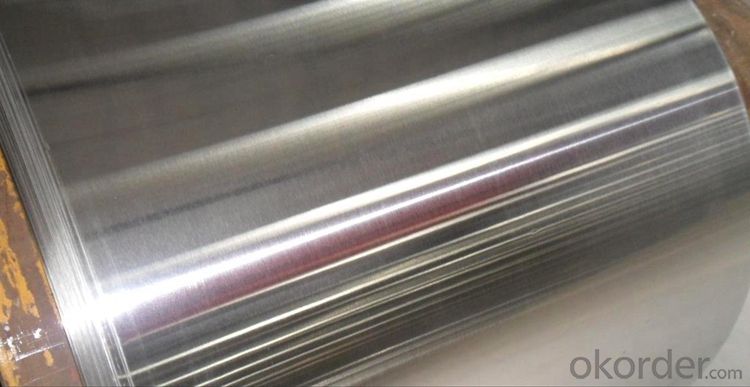

Products Description for Stainless Steel Coils/Sheets:

Item | cold rolled 201 stainless steel coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,430 |

Surface | NO.1,2b,4K,8k,HL,mirror finish |

Thickness | 0.3-100mm |

Width | 500-2000mm |

Price term | FOB,CFR,CIF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: What is the bending strength of stainless steel sheets?

- The bending strength of stainless steel sheets can vary depending on the specific grade and thickness of the sheet. However, stainless steel is generally known for its high strength and rigidity, making it suitable for various applications that require strong and durable materials.

- Q: Can stainless steel sheets be used for fermentation tanks?

- Yes, stainless steel sheets can be used for fermentation tanks. Stainless steel is a preferred material for fermentation tanks due to its durability, corrosion resistance, and ability to maintain the desired temperature. It is non-reactive, which means it does not interact with the fermenting substances, ensuring the purity and quality of the product. Stainless steel is also easy to clean and sanitize, which is crucial for maintaining hygienic conditions during the fermentation process. Additionally, stainless steel sheets can be fabricated into various shapes and sizes to meet specific fermentation tank requirements. Overall, stainless steel sheets are a reliable and popular choice for fermentation tanks in various industries, including brewing, winemaking, and food processing.

- Q: Do stainless steel sheets have a specific weight?

- Yes, stainless steel sheets have a specific weight. The weight of a stainless steel sheet depends on its dimensions (length, width, and thickness) as well as the specific type and grade of stainless steel used.

- Q: What are the different types of stainless steel sheet patterns?

- Stainless steel sheet patterns come in a variety of options. Some of the most commonly used patterns are as follows: 1. The plain or smooth pattern: This pattern is the simplest and most basic, offering a smooth and flat surface. 2. The diamond pattern, also known as tread plate or checker plate: This pattern has raised diamond-shaped ridges, providing excellent slip resistance. 3. The tear drop pattern: Similar to the diamond pattern, this one has raised teardrop-shaped ridges, offering enhanced slip resistance. 4. The linen pattern: This pattern resembles the texture of linen fabric, with a series of parallel lines intersected by a crisscross pattern. 5. The quilted pattern: Resembling a quilted fabric, this pattern has a diamond-shaped or square-shaped design. 6. The hammered pattern: With a textured surface resembling the marks left by a hammer, this pattern adds visual interest and dimension. 7. The perforated pattern: Featuring small holes or perforations in the sheet, this pattern allows for improved ventilation and drainage in certain applications. These examples represent just a fraction of the stainless steel sheet patterns available. Each pattern offers unique aesthetic and functional advantages, providing greater versatility in design and application.

- Q: Can stainless steel sheets be used for countertops?

- Certainly! Countertops can indeed be made using stainless steel sheets. Stainless steel is a material known for its durability and versatility, as it possesses resistance against stains, heat, and bacteria. Consequently, it proves to be an exceptional option for kitchen countertops. Moreover, stainless steel countertops are effortless to clean and maintain, all while presenting a sleek and contemporary look. While commonly found in commercial kitchens, these countertops are steadily gaining popularity in residential settings, owing to their durable nature and hygienic qualities.

- Q: Can stainless steel sheets be used for bus shelters?

- Bus shelters can indeed utilize stainless steel sheets. This material, known for its durability and resistance to corrosion, proves ideal for outdoor structures such as bus shelters. Come rain, snow, or UV rays, stainless steel withstands diverse weather conditions without succumbing to deterioration or rust. Moreover, the sleek and contemporary look provided by stainless steel sheets enhances the overall visual allure of the bus shelter. Furthermore, the ease with which stainless steel can be cleaned and maintained guarantees the long-lasting nature of the bus shelter.

- Q: What is the thermal expansion coefficient of stainless steel sheets?

- The thermal expansion coefficient of stainless steel sheets typically ranges from 10.5 to 12.5 x 10^-6 per degree Celsius.

- Q: What are the benefits of using patterned stainless steel sheets in interior design?

- Using patterned stainless steel sheets in interior design offers numerous benefits. Firstly, these sheets provide a unique and modern aesthetic to any space. The patterns etched into the stainless steel can range from geometric designs to intricate motifs, adding a touch of elegance and visual interest to walls, ceilings, or furniture. This can enhance the overall ambiance of a room and make it stand out. Secondly, patterned stainless steel sheets are highly durable and long-lasting. Stainless steel is known for its strength and resistance to corrosion, making it an ideal material for interior design applications. These sheets can withstand daily wear and tear, making them suitable for high-traffic areas such as restaurants, hotels, or public spaces. Moreover, patterned stainless steel sheets are low maintenance. Unlike other materials, stainless steel is easy to clean and does not require special care or regular maintenance. Simple wiping with a damp cloth or using mild cleaning agents is sufficient to keep the sheets looking pristine. This makes them a practical choice for interior design, especially in areas where hygiene is crucial. Additionally, patterned stainless steel sheets offer versatility in design. They can be used in various applications, including wall cladding, room dividers, backsplashes, or even as decorative accents. With a wide range of patterns and finishes available, designers have the freedom to create unique and customized looks to suit any style or theme. Lastly, using patterned stainless steel sheets in interior design is environmentally friendly. Stainless steel is a recyclable material, meaning it can be reused or repurposed without causing harm to the environment. By incorporating sustainable materials into interior design, we contribute to reducing waste and promoting eco-conscious practices. Overall, the benefits of using patterned stainless steel sheets in interior design include their aesthetic appeal, durability, low maintenance requirements, versatility, and environmental friendliness. These sheets offer a practical and visually pleasing solution to elevate the design of any space.

- Q: Are stainless steel sheets suitable for outdoor railings?

- Yes, stainless steel sheets are suitable for outdoor railings. Stainless steel is highly resistant to corrosion and has excellent durability, making it a popular choice for outdoor applications. It is also able to withstand harsh weather conditions, including rain, snow, and UV radiation, without losing its structural integrity or appearance. Stainless steel railings are low maintenance and easy to clean, making them a practical and long-lasting option for outdoor spaces. Additionally, stainless steel sheets offer a sleek and modern aesthetic, enhancing the overall look and feel of any outdoor railing system.

- Q: What are the common grades of stainless steel sheets used in construction?

- The common grades of stainless steel sheets used in construction include 304, 316, and 430.

Send your message to us

Steel Coils 200 Series Steel Plate Steel Sheets Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords