Stainless Steel Coils 200 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

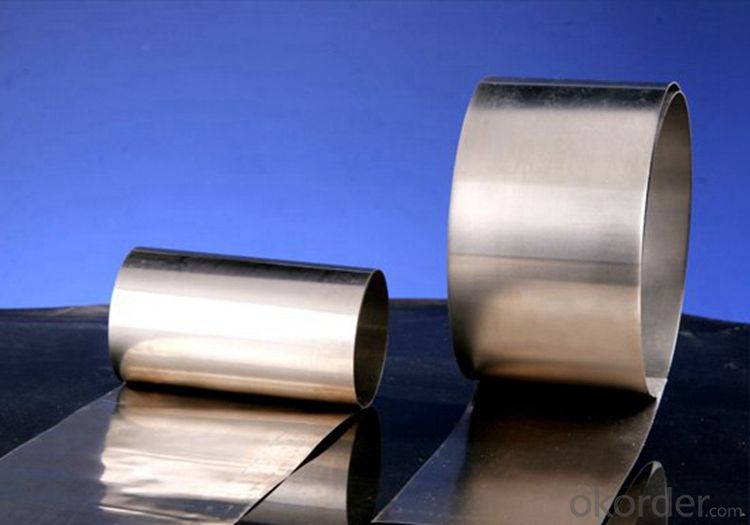

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for mezzanine flooring?

- Yes, stainless steel sheets can be used for mezzanine flooring. Stainless steel is a durable and corrosion-resistant material, making it suitable for various applications including flooring. It has high strength and can withstand heavy loads, making it ideal for mezzanine structures. Additionally, stainless steel sheets can be easily cleaned and maintained, ensuring a hygienic and aesthetically pleasing flooring option.

- Q: How do I prevent galvanic corrosion on stainless steel sheets?

- There are several measures that can be taken to prevent galvanic corrosion on stainless steel sheets: 1. Opt for a suitable stainless steel alloy: Select a grade of stainless steel, such as 316 or 317, which is less susceptible to galvanic corrosion compared to 304 stainless steel. 2. Keep dissimilar metals separate: Avoid direct contact between stainless steel sheets and other metals, particularly those with a higher potential for galvanic corrosion. If contact is necessary, use insulating materials like gaskets or rubber pads to create a barrier between the metals. 3. Apply protective coatings: Use specially designed protective coatings or paints for stainless steel to create a barrier that shields against galvanic corrosion. These coatings act as sacrificial layers, safeguarding the stainless steel from direct contact with corrosive substances. 4. Utilize isolation materials: Install insulating materials, such as plastic washers, insulating tape, or non-conductive gaskets, between stainless steel sheets and other dissimilar metals. This prevents direct electrical contact and subsequent corrosion. 5. Maintain proper upkeep: Regularly clean and inspect stainless steel sheets to remove any contaminants or foreign substances that may contribute to corrosion. Avoid using abrasive cleaners or tools that could damage the protective layer of the stainless steel. 6. Employ electrochemical protection: Implement cathodic protection techniques, such as sacrificial anodes or impressed current systems, to introduce an external source of electrons that counteracts galvanic corrosion. These methods help shift the corrosion potential of the stainless steel sheets to a more passive range. By adhering to these preventive measures, the risk of galvanic corrosion on stainless steel sheets can be significantly reduced. This ensures their longevity and helps maintain their structural integrity.

- Q: What are the main chemical constituents of stainless steel plates?

- Stainless steel not only refers to a stainless steel, but more than one hundred kinds of industrial stainless steel, the development of each kind of stainless steel in its specific application areas have good performance. The key to success is to find out what the purpose is, and then determine the correct type of steel. There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q: What do stainless steel 304 industrial surfaces refer to?

- Acid washing: pickling is the removal of oxide and rust on the surface of iron and steel by means of acid solutions. The parts are usually immersed in aqueous solutions such as sulfuric acid to remove oxides such as oxides on the metal surface. It is the pretreatment or intermediate treatment of electroplating, enamel and rolling etc..

- Q: How do you prevent stress corrosion cracking in stainless steel sheets?

- To prevent stress corrosion cracking in stainless steel sheets, several measures can be taken. First and foremost, selecting the appropriate grade of stainless steel that is resistant to stress corrosion is crucial. Additionally, avoiding exposure to corrosive environments, such as chloride-containing solutions or high temperatures, is important. It is also recommended to minimize or eliminate tensile stresses through proper handling, fabrication, and installation techniques. Lastly, implementing regular inspection and maintenance practices can help detect any signs of stress corrosion cracking early on and take necessary preventive measures.

- Q: Are stainless steel sheets suitable for railway station platforms?

- Yes, stainless steel sheets are suitable for railway station platforms. Stainless steel is a highly durable material that can withstand heavy foot traffic and extreme weather conditions, making it an ideal choice for platforms in railway stations. It is resistant to corrosion, which is crucial in areas exposed to moisture, such as platforms where rain, snow, or spilled liquids may occur. Stainless steel sheets are also easy to clean and maintain, ensuring a hygienic and safe environment for passengers. Additionally, stainless steel has a sleek and modern appearance, adding to the aesthetic appeal of the railway station. Overall, stainless steel sheets provide the necessary strength, durability, and aesthetic qualities required for railway station platforms.

- Q: Can stainless steel sheets be used for swimming pool construction?

- Indeed, swimming pool construction can utilize stainless steel sheets. Stainless steel, being a robust and corrosion-resistant material, proves to be an exceptional selection for pool construction. Its ability to endure chemicals and withstand the harsh swimming pool conditions, such as exposure to chlorine and saltwater, is highly commendable. Moreover, stainless steel sheets are effortless to clean and maintain, rendering them a popular choice for both residential and commercial swimming pools. Additionally, stainless steel adds a touch of sophistication and modernity, ultimately enhancing the pool's overall appearance. However, it is crucial to guarantee the usage of high-quality stainless steel sheets that meet industry standards to ensure prolonged performance and safety.

- Q: Are stainless steel sheets suitable for elevator doors?

- Yes, stainless steel sheets are suitable for elevator doors. Stainless steel is a durable and corrosion-resistant material that can withstand the wear and tear associated with elevator use. It also offers a sleek and modern appearance, making it a popular choice for elevator doors in various settings.

- Q: What is the function of a stainless steel plate at the top of the steel chimney?

- 316 and 317 stainless steel (see below the performance of 317 stainless steel) is a stainless steel containing molybdenum. The molybdenum content in 317 stainless steel with 316 stainless steel. Due to a little of molybdenum in steel, the steel overall performance is better than 310 and 304 stainless steel, high temperature, when the concentration of sulfuric acid is less than 15% and more than 85%, 316 stainless steel has been widely used. 316 stainless steel also has good chloride corrosion resistance, so it is often used in marine environments.

- Q: What is the minimum thickness available for stainless steel sheets?

- The minimum thickness of stainless steel sheets can differ depending on the grade and manufacturer. Nevertheless, typically stainless steel sheets are readily obtainable in thicknesses that span from 0.4mm to 6mm. Certain manufacturers might even offer thinner sheets, like 0.3mm, for particular applications. To ascertain the precise minimum thickness that suits your specific needs, it is crucial to consult with the supplier or manufacturer.

Send your message to us

Stainless Steel Coils 200 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords