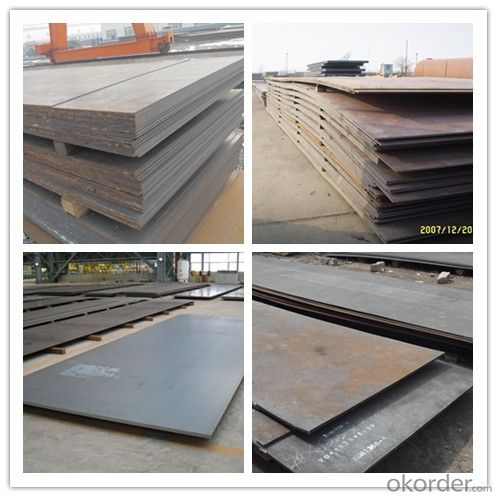

Hot Rolled Steel Sheets in Coils Steel Coil China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,DIN,JIS

Technique:

Hot Rolled

Shape:

Round

Surface Treatment:

Oiled,Dry

Steel Grade:

Q195,Q215,Q235

Certification:

ISO,SGS,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

according to weight

Net Weight:

23mt

Packaging:

Standard Export Packing

Hot Rolled Steel Sheet Plate Specifications:

1) Thickness: 1.5-75mm

2) Width: 1010-2500mm

3) Coil Weight: 1.7 - 10MT or as your request

4) Technical process: Steel Billet, Heated, Rolled, Coil

5) MOQ: 25mts

6) Payment terms: L/C OR TT

7) Uses: making pipes, cold strip-welded pipes, cold-bent shaped-steel, bicycle structures, small-sized press-pieces and household decoration goods

8) Sheet packed by box: 0.70-2.0mm x 1000mm x 2000mm

9) Each box weight: 3768kgs

HRC/ Hot Rolled Steel Coils:

| Material | Q195/Q235/ST12/ST13/ST14 |

| Standard | ASTM ;BS;JIS;DIN;GB |

| Inner Diameter | 508mm/610mm |

| Length | can be done as your requirements. |

| Thickness | 0.13mm-4.0mm (W.T tolerance ±1%) |

| Width | Strip:20-600mm |

| Coil weight | 3-5 tons |

| Surface | Oiled;Skin-passed;passivation |

| End | EC/EM |

| Technology | Cold rolled/annealing |

| Related products | Gi sheet |

| Usage | common structural parts and parts for drawing in engineering machines transportation machine construction machines, lifting machine, agricultural machines, light and civil industrial, household appliance industries. chemical equipments, drive casing pipe and light industrial civil industries. |

- Q: What are the factors affecting the strength of steel coils?

- The factors affecting the strength of steel coils include the composition of the steel, the manufacturing process used, the temperature and time of heat treatment, the presence of impurities or defects, and the degree of deformation during processing.

- Q: I recently got in a car accident with a steel mailbox, on a snowy day. I was wondering if i can do anything since the steel mailbox caused my car to be totaled. Otherwise it would have been fine and would have suffered only minor damage. Anything I can do here to maybe get some money back? Thanks!

- Let me get this straight. You were driving too fast for conditions, lost control due to driving too fast, hit a stationary mailbox, car is totaled due to driving too fast for conditions, and you want to be reimbursed? Sorry, you are dead wrong. It is your duty to maintain control of your car at all times. If there was any damage to the mailbox, you are the one liable.

- Q: What are the common uses of stainless steel coils?

- Stainless steel coils are commonly used in a variety of industries for applications such as manufacturing automotive parts, appliances, construction materials, and HVAC systems. They are also utilized in the production of kitchen utensils, medical equipment, and food processing machinery due to their corrosion resistance, durability, and heat resistance properties.

- Q: What are the different methods of stretch leveling steel coils?

- There are several methods of stretch leveling steel coils, each with its own advantages and applications. 1. Roller Leveling: This method involves passing the steel coil through a series of rollers that apply pressure to stretch and flatten the material. It is a widely used method for leveling steel coils and offers good control over the leveling process. Roller leveling is suitable for thin and medium gauge steel coils. 2. Tension Leveling: In this method, the steel coil is subjected to high tension forces applied by a set of bridle rolls. The tension helps to elongate and flatten the material, resulting in a level and stress-free coil. Tension leveling is particularly effective for thicker and harder steel coils. 3. Laser Leveling: Laser technology is employed in this method to measure and correct any imperfections in the steel coil. A laser scanner scans the surface of the coil and detects variations, which are then adjusted by a laser beam. Laser leveling offers high precision and is suitable for leveling sensitive and high-value steel coils. 4. Stretcher Leveling: This method involves stretching the steel coil beyond its yield point, which causes the material to permanently deform and eliminate any residual stresses. Stretcher leveling is commonly used for heavy gauge coils and can achieve significant flatness improvements. 5. Tensionless Leveling: As the name suggests, tensionless leveling is performed without applying tension to the steel coil. Instead, hydraulic or pneumatic pressure is used to stretch and flatten the material. This method is suitable for delicate or sensitive steel coils that may be prone to damage under high tension forces. Each method of stretch leveling steel coils has its own advantages, such as control, precision, or suitability for specific types of steel coils. The choice of method depends on factors like the thickness, hardness, and quality requirements of the steel coil, as well as the desired flatness and surface finish.

- Q: How are steel coils used in the production of automotive engine components?

- Steel coils are used in the production of automotive engine components by being processed and shaped into various parts, such as pistons, crankshafts, and connecting rods. The coils are first cut, stamped, and formed into the desired shapes, and then undergo heat treatment and other machining processes to enhance their strength and durability. These components are crucial for the proper functioning of an automotive engine, as they provide structural support and help convert the energy generated by the combustion process into mechanical motion.

- Q: I am getting a barn soon and I was debating between wood, and steel. I think steel would look nicer [painted of course] and I was wondering which is cheaper. Any extra info would be great. Thanks x

- Steel barns are much cheaper, but do require more insulation (they get extremely hot in summer and extremely cold in winter w/o insulation), and they have little to no maintinence. in my opinion though, a better-built wood barn is by far the better choice in the long run. They are much more sturdy, more visually appealing (to me), and if kept up well, will last much longer than a steel barn will. I also like that with a wood barn, during rain/hail/etc.etc. you don't have a deafening clatter that is unavoidable with steel barns.

- Q: Are steel coils recyclable?

- Yes, steel coils are recyclable. Steel is one of the most commonly recycled materials in the world. Coils made of steel can be easily melted down and used to produce new steel products, making them a valuable resource for recycling.

- Q: What are the main factors that affect the strength of steel coils?

- The main factors that affect the strength of steel coils include the composition and quality of the steel used, the manufacturing process employed, the thickness and width of the coils, and the presence of any impurities or defects. Additionally, factors such as temperature, humidity, and storage conditions can also impact the strength of steel coils.

- Q: Why is it usually scorned by the shooting community to use steel cased ammo (like Wolf)? Always hear corrosive and steel is bad for the extractor/firing pin. Hulp a simpleton out!

- I okorder /

- Q: How do steel coil manufacturers minimize waste and maximize efficiency?

- Steel coil manufacturers can minimize waste and maximize efficiency through a combination of advanced technology, process optimization, and waste management practices. One way to achieve this is by using advanced automation and control systems in the production process. These systems can monitor and adjust various parameters such as temperature, pressure, and speed, ensuring that the manufacturing process operates at the optimal level. By closely monitoring and controlling these parameters, manufacturers can reduce the occurrence of defects and errors, which in turn minimizes waste. Another approach is to implement lean manufacturing principles. This involves eliminating any non-value-adding activities and streamlining the production process to reduce waste and increase efficiency. By carefully analyzing the entire production workflow, manufacturers can identify areas that can be improved, such as reducing setup times, eliminating bottlenecks, and optimizing material flow. This results in a more efficient and streamlined production process, minimizing waste and maximizing productivity. Furthermore, steel coil manufacturers can implement effective waste management practices. This includes proper handling and disposal of waste materials, as well as implementing recycling programs. By separating and recycling materials such as scrap metal, manufacturers can reduce the amount of waste generated and minimize the environmental impact of their operations. Additionally, manufacturers can explore partnerships with recycling companies to ensure that waste materials are properly managed and recycled. In summary, steel coil manufacturers can minimize waste and maximize efficiency by utilizing advanced technology, implementing lean manufacturing principles, and implementing effective waste management practices. By continuously striving for improvement and optimization in their processes, manufacturers can reduce waste, increase productivity, and ultimately achieve higher levels of efficiency.

Send your message to us

Hot Rolled Steel Sheets in Coils Steel Coil China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords