Stainless Steel Coils 300 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

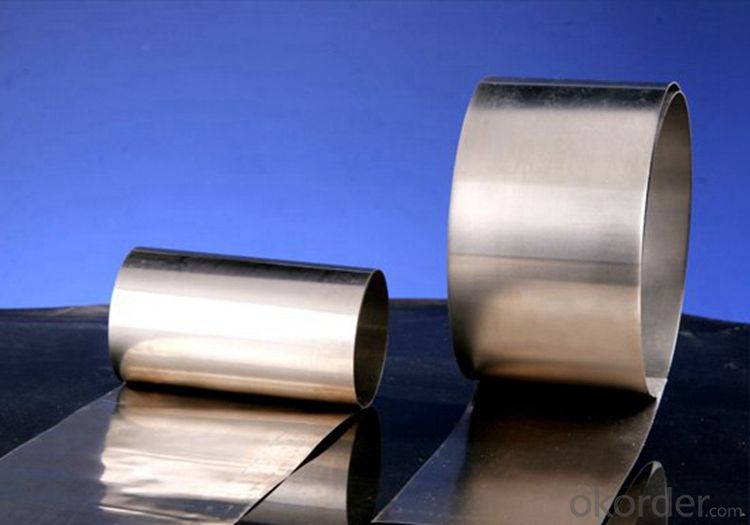

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What are the benefits of using textured stainless steel sheets in decorative lighting fixtures?

- Using textured stainless steel sheets in decorative lighting fixtures offers several advantages. To begin with, these sheets bring a unique and visually appealing element to the fixture. The texture adds depth and dimension, making it a standout feature that captures attention in any space. Whether it's a hammered, brushed, or embossed texture, it adds elegance and sophistication to the overall design. Moreover, stainless steel is highly durable and long-lasting. It resists corrosion, rust, and damage caused by moisture or humidity, making it ideal for lighting fixtures, especially in outdoor or high-moisture environments. The textured surface also helps conceal any potential scratches or marks that may occur over time, ensuring a consistently attractive appearance. Additionally, stainless steel is easy to clean and maintain. The smooth surface of the textured sheets allows for effortless removal of dirt, fingerprints, and smudges, keeping the lighting fixture looking polished and clean. Furthermore, stainless steel boasts excellent light reflectivity properties. The textured surface enhances the dispersion of light, creating captivating patterns and shadows. This contributes to a unique ambiance in the surrounding area and produces visually stunning effects. Lastly, stainless steel is a sustainable and eco-friendly material. It is 100% recyclable, making it an environmentally responsible choice for lighting fixtures. By utilizing textured stainless steel sheets, we can help reduce our carbon footprint and contribute to a greener future. In conclusion, the numerous benefits of using textured stainless steel sheets in decorative lighting fixtures include adding a visually appealing element, durability and longevity, ease of cleaning and maintenance, excellent light reflectivity properties, and environmental friendliness. These advantages make textured stainless steel sheets an excellent choice for creating stunning and sustainable lighting fixtures.

- Q: What are the limitations of using stainless steel sheets?

- There are several limitations associated with using stainless steel sheets. Firstly, stainless steel sheets can be quite expensive compared to other materials. This can make it less feasible for certain budget-conscious projects or applications. Secondly, stainless steel sheets are relatively heavy, which can make them difficult to handle and install, especially in large quantities. This can increase labor costs and require additional equipment for transportation and installation. Thirdly, stainless steel sheets are prone to scratching and denting. While stainless steel is known for its durability, it is not entirely resistant to physical damage. Scratches and dents can diminish the appearance and functionality of the sheets, particularly in high-traffic areas or environments where there is a risk of impact. Additionally, stainless steel sheets can be susceptible to corrosion, although to a lesser extent compared to other metals. In certain conditions, such as exposure to saltwater or harsh chemicals, stainless steel sheets may develop rust or other forms of corrosion. Regular maintenance and proper care are necessary to prevent or minimize this issue. Another limitation is that stainless steel sheets have limited color options. They generally come in shades of silver or gray, which may not be suitable for projects that require specific colors or aesthetics. Lastly, stainless steel sheets have poor insulation properties. They conduct heat and cold more efficiently than other materials, which can result in greater energy loss and higher heating or cooling costs. In applications where insulation is crucial, additional measures or alternative materials may be required. In conclusion, while stainless steel sheets offer numerous advantages such as strength, corrosion resistance, and durability, they also have limitations in terms of cost, weight, susceptibility to damage, corrosion, limited color options, and poor insulation properties. Understanding these limitations is crucial when considering the use of stainless steel sheets in various applications.

- Q: Can stainless steel sheets be used for filtration applications?

- Yes, stainless steel sheets can be used for filtration applications. Stainless steel is known for its corrosion resistance, durability, and high strength, making it suitable for various filtration processes. It can effectively filter out particles, contaminants, and impurities in liquids and gases, making it a popular choice for industries such as food and beverage, pharmaceutical, chemical, and wastewater treatment.

- Q: Can stainless steel sheets be polished or brushed?

- Yes, stainless steel sheets can be both polished and brushed. Polishing stainless steel sheets involves using abrasive compounds to remove any imperfections or scratches from the surface, resulting in a smooth and reflective finish. On the other hand, brushing stainless steel sheets involves using abrasive pads or brushes to create a textured pattern or finish. This process creates a brushed appearance with fine parallel lines that can be either horizontal or vertical. Both polishing and brushing techniques can enhance the aesthetic appeal of stainless steel sheets and make them more resistant to corrosion.

- Q: Can stainless steel sheets be used for solar panel frames?

- Yes, stainless steel sheets can be used for solar panel frames. Stainless steel is a popular choice for solar panel frames due to its high strength, durability, and corrosion resistance properties. It can withstand various weather conditions, including extreme heat, humidity, and exposure to sunlight. Additionally, stainless steel is non-magnetic and non-combustible, making it a safe choice for solar panel installations. Its high strength-to-weight ratio also allows for lighter frame designs, reducing the overall weight of the solar panels and making them easier to install. Overall, stainless steel sheets are a reliable and long-lasting option for constructing solar panel frames.

- Q: Are stainless steel sheets suitable for nuclear power plants?

- Stainless steel sheets are well-suited for nuclear power plants due to their unique properties that make them ideal for such hazardous environments. Firstly, their exceptional corrosion resistance is crucial in plants with high levels of corrosive substances. Corrosion can compromise materials' structural integrity, leading to safety risks and potential failures. Therefore, stainless steel's resistance to corrosion ensures the longevity and reliability of equipment and structures in nuclear power plants. Secondly, stainless steel possesses high strength and toughness, enabling it to withstand extreme conditions like high temperatures and pressures found in these facilities. This strength and toughness allow stainless steel to endure the harsh environment and potential mechanical stresses that may arise during normal operations or accidents. Moreover, stainless steel exhibits excellent heat resistance, a critical characteristic in nuclear power plants where nuclear fission generates high temperatures. Stainless steel's ability to maintain its strength and structural integrity even at elevated temperatures makes it suitable for containing and handling radioactive materials and hot fluids. Additionally, stainless steel is easy to clean and maintain, which is vital in nuclear power plants where cleanliness and sterility are paramount. Regular cleaning and maintenance are necessary to prevent the accumulation of radioactive contaminants and ensure the safe and efficient operation of equipment and systems. In conclusion, stainless steel sheets are highly suitable for use in nuclear power plants due to their corrosion resistance, strength, toughness, heat resistance, and ease of maintenance. Their utilization ensures the safety, reliability, and durability of equipment and structures, thereby enhancing the overall efficiency and effectiveness of nuclear power plants.

- Q: Can stainless steel sheets be used for athletic equipment?

- Yes, stainless steel sheets can be used for athletic equipment. Stainless steel is known for its durability, corrosion resistance, and strength, making it an ideal material for various athletic equipment applications. It is commonly used in the construction of gym equipment such as weightlifting bars, dumbbells, and exercise benches. Stainless steel sheets are also used to manufacture basketball hoops, soccer goalposts, and other outdoor sports equipment due to their ability to withstand harsh weather conditions. Additionally, stainless steel sheets can be customized and fabricated into different shapes and sizes, making them versatile for various athletic equipment needs.

- Q: What is the impact resistance of stainless steel sheets?

- Stainless steel sheets have a high impact resistance due to their unique properties and composition. The impact resistance refers to the ability of a material to withstand sudden loads or forces without breaking or deforming permanently. Stainless steel sheets possess excellent toughness and durability, making them highly resistant to impact. The impact resistance of stainless steel sheets can be attributed to their high tensile strength and ductility. Stainless steel is an alloy that contains iron, chromium, and other elements, which impart its strength and corrosion resistance. The addition of chromium forms a protective oxide layer on the surface of the steel, preventing it from rusting or corroding easily. Furthermore, stainless steel sheets are available in various grades, each with its specific composition and properties. The most commonly used grade for impact-resistant applications is 304 stainless steel, which offers good resistance to impact and is widely used in industries such as construction, automotive, and aerospace. The impact resistance of stainless steel sheets also depends on their thickness. Thicker sheets tend to have higher impact resistance due to their increased mass and structural integrity. However, even thinner stainless steel sheets can still provide considerable impact resistance due to the inherent strength and toughness of the material. In practical applications, stainless steel sheets are often used in environments where impact resistance is critical, such as in the manufacturing of machinery, equipment, and structures subjected to high loads or potential impacts. They can withstand heavy impacts without cracking, fracturing, or deforming, thus ensuring the integrity and longevity of the finished product. Overall, stainless steel sheets possess an excellent impact resistance that makes them a preferred choice in various industries. Their high strength, corrosion resistance, and durability make them suitable for applications where resistance to impact is essential.

- Q: Are stainless steel sheets suitable for outdoor sculptures or artwork?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or artwork. Stainless steel is known for its durability, corrosion resistance, and ability to withstand harsh weather conditions. It can maintain its appearance and integrity even when exposed to rain, sun, and other environmental factors. Additionally, stainless steel offers a sleek and modern aesthetic, making it a popular choice for outdoor sculptures or artwork.

- Q: What brand of stainless steel plate is good?

- It is an alloy steel which is not easily rusted, but it is not absolutely rusty. Stainless steel plate refers to the atmosphere, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel plate. Stainless steel plate has been published since the beginning of twentieth Century, and now has a history of more than 1 centuries.

Send your message to us

Stainless Steel Coils 300 Series Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords