Stainless Steel Coils 200 Series/300 Series/400Series From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

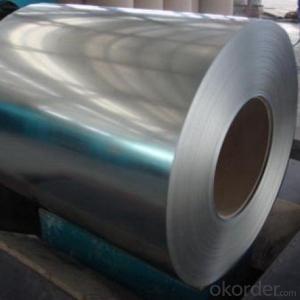

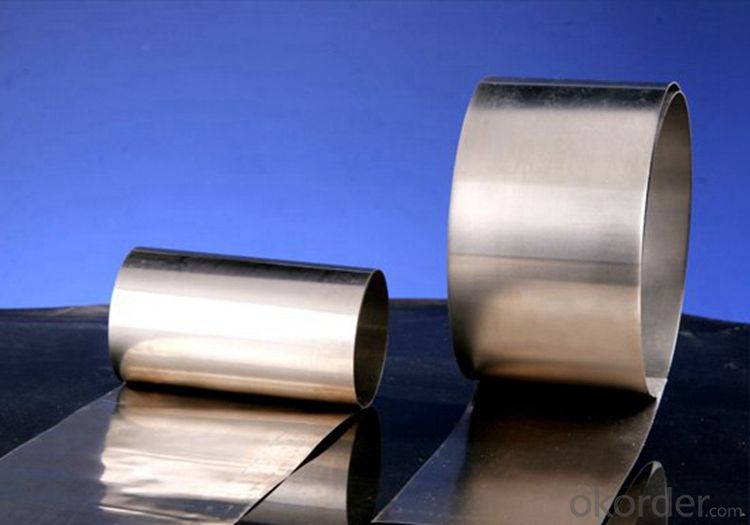

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for elevator panels?

- Yes, stainless steel sheets can be used for elevator panels. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevators. It offers a sleek and modern aesthetic, making it a popular choice for elevator panels in commercial and residential buildings.

- Q: What are the different methods of cutting stainless steel sheets?

- There are several methods available for cutting stainless steel sheets, depending on the specific requirements and desired precision. 1. Shearing: This is one of the most common methods used for cutting stainless steel sheets. It involves using a shearing machine with sharp blades to cut through the material. Shearing is ideal for straight cuts and is relatively fast and cost-effective. 2. Laser cutting: Laser cutting is a highly precise method that uses a high-powered laser beam to cut through stainless steel sheets. It provides a clean and smooth cut, and can be used to create intricate designs or complex shapes. Laser cutting is widely used in industries that require high precision and quality finishes. 3. Plasma cutting: Plasma cutting uses a high-temperature plasma arc to melt through stainless steel sheets. This method is suitable for cutting thick stainless steel sheets or materials with high conductivity. Plasma cutting offers fast cutting speeds and can handle various shapes and thicknesses. 4. Waterjet cutting: Waterjet cutting involves using a high-pressure jet of water mixed with abrasive particles to cut through stainless steel sheets. This method is highly versatile and can create complex shapes with high precision. Waterjet cutting is also a cold cutting process, which means it does not produce heat-affected zones or alter the material's structure. 5. Abrasive cutting: This method uses an abrasive wheel or disc to grind and cut through stainless steel sheets. It is commonly used for rough cuts or in situations where other methods are not feasible. Abrasive cutting can be done manually or with the help of power tools, such as angle grinders. Each of these cutting methods has its own advantages and limitations, and the choice of method depends on factors such as the thickness of the stainless steel sheet, desired precision, budget, and production requirements.

- Q: Can stainless steel sheets be recycled after use?

- Stainless steel sheets are indeed recyclable once they have served their purpose. This material is highly recyclable and possesses qualities that make it perfectly suited for recycling. The process of recycling stainless steel entails melting the sheets to extract the raw materials, which can subsequently be utilized in manufacturing new stainless steel products. By recycling stainless steel, not only are we conserving natural resources, but we are also reducing energy consumption and the emission of greenhouse gases that are typically associated with the production of fresh stainless steel. Therefore, it is strongly advised to recycle stainless steel sheets in order to foster sustainability and promote the principles of a circular economy.

- Q: Are stainless steel sheets suitable for architectural wire mesh?

- Yes, stainless steel sheets are suitable for architectural wire mesh. Stainless steel is a durable and corrosion-resistant material, making it ideal for outdoor applications. It provides strength and stability to the wire mesh, ensuring longevity and aesthetic appeal in architectural designs.

- Q: How do you join stainless steel sheets together?

- There are various methods to join stainless steel sheets together, depending on the specific application and desired outcome. Here are a few common techniques: 1. Welding: Stainless steel can be welded using various methods such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or spot welding. Welding creates a strong and durable bond between the sheets, ensuring a secure connection. 2. Mechanical Fasteners: Using mechanical fasteners like screws, bolts, or rivets can be an effective way to join stainless steel sheets. This method is often used when disassembly or reassembly is required, as it allows for easy removal and reinstallation. 3. Adhesive Bonding: Specialized adhesives designed for stainless steel can be used to join sheets together. These adhesives create a strong bond while maintaining the aesthetics of the stainless steel surface. However, adhesive bonding may not be suitable for high-stress or high-temperature applications. 4. Clinching: Clinching involves using a special tool to press the stainless steel sheets together, creating a mechanical interlock. This method is commonly used for joining thin sheets and offers a cost-effective and fast solution. It is important to choose the appropriate method based on the specific requirements of the project, including factors such as load-bearing capacity, temperature, corrosion resistance, and aesthetics. Consulting with a professional or conducting thorough research can help ensure the chosen joining technique is suitable for the intended application.

- Q: How do you prevent galvanic corrosion when using stainless steel sheets?

- To prevent galvanic corrosion when using stainless steel sheets, there are several measures you can take: 1. Avoid direct contact with dissimilar metals: Galvanic corrosion occurs when two different metals come into contact in the presence of an electrolyte, such as moisture. To prevent this, ensure stainless steel sheets are not in direct contact with dissimilar metals, especially those with a higher anodic index, such as aluminum or copper. If contact is unavoidable, use insulating materials like plastic or rubber gaskets to separate the metals. 2. Select compatible fasteners: When fastening stainless steel sheets, it is crucial to choose fasteners made from the same or compatible metals. Using dissimilar metals can create galvanic cells, leading to corrosion. Stainless steel fasteners or those made from materials with similar corrosion resistance, like galvanized steel, are recommended. 3. Use protective coatings: Applying protective coatings to stainless steel sheets can provide an additional barrier against galvanic corrosion. Consider using paint, epoxy, or other appropriate coatings that are compatible with stainless steel. These coatings act as a sacrificial layer, preventing direct contact between the stainless steel and the surrounding environment. 4. Insulate electrical connections: If stainless steel sheets are involved in electrical systems, ensure proper insulation of electrical connections. This prevents the flow of electrical current between dissimilar metals, reducing the risk of galvanic corrosion. Insulating materials like plastic or rubber sleeves can be used to separate the metals and inhibit the formation of galvanic cells. 5. Control environmental factors: Galvanic corrosion is often accelerated in the presence of moisture, saltwater, or acidic environments. Controlling these factors can help prevent corrosion on stainless steel sheets. Regularly clean and dry the sheets, especially in areas where moisture accumulates. Avoid exposing the sheets to saltwater or corrosive chemicals, and maintain proper ventilation to minimize humidity levels. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using stainless steel sheets. However, it is important to regularly inspect the sheets for any signs of corrosion and address them promptly to maintain their integrity and longevity.

- Q: Stainless steel plate laser cutting how to charge?

- It's plasma cutting... In fact, if the process is not required, you can buy a hand grinder with cutting pieces.

- Q: Are stainless steel sheets suitable for decorative purposes?

- Stainless steel sheets are a perfect choice for decorative purposes. They possess a sleek and contemporary appearance, which adds a touch of elegance and sophistication to any given space. The smooth and reflective surface of stainless steel creates a visually pleasing aesthetic that enhances the overall look and feel of a room. Furthermore, stainless steel is incredibly durable and corrosion-resistant, making it an excellent long-term option for decorative use. The versatility of stainless steel sheets allows them to be utilized in various decorative forms, including wall panels, backsplashes, countertops, and even furniture. Regardless of whether they are used in residential or commercial settings, stainless steel sheets can be employed to create remarkable and attention-grabbing decorative elements that perfectly complement any interior design style.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it ideal for storage racks that may be exposed to moisture or other harsh conditions. Stainless steel sheets can be fabricated into various shapes and sizes to suit different storage needs, and they can support heavy loads without warping or bending. Additionally, stainless steel is easy to clean and maintain, ensuring a hygienic storage environment. Overall, stainless steel sheets are a reliable choice for storage racks in industries such as food and beverage, pharmaceuticals, and warehouses.

- Q: Are stainless steel plates 3.4mm or 3.5mm thick?

- There are stainless steel sheets in these two specifications.According to standard GB/T 708-2006 cold rolled steel sheet size tolerances, the stainless steel sheet thickness is 0.3~4 mm,

Send your message to us

Stainless Steel Coils 200 Series/300 Series/400Series From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords