400 Series Hot Rolled Stainless Steel Coils/Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Specifications for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

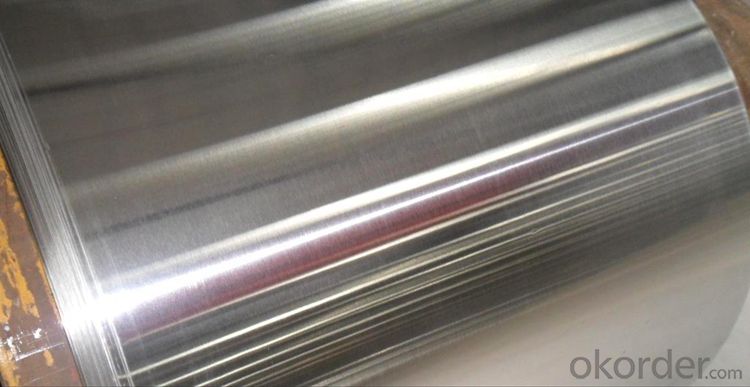

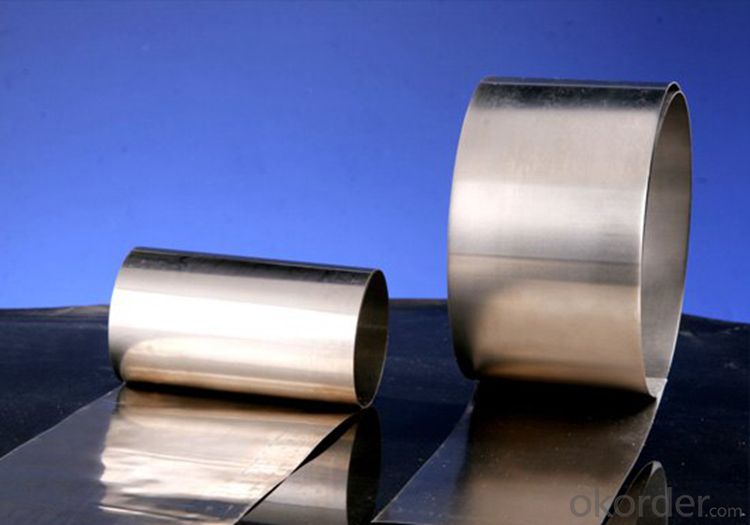

Detail picture for Stainless Steel

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for elevator floors?

- Yes, stainless steel sheets can be used for elevator floors. Stainless steel is a durable and hygienic material that is resistant to corrosion and staining, making it a suitable choice for elevator flooring.

- Q: How do you remove oil stains from stainless steel sheets?

- In order to eliminate oil stains from stainless steel sheets, the following steps can be followed: 1. To start, utilize a clean cloth or paper towel to wipe the affected area and remove any excess oil or grease. 2. Combine a mild dish soap with warm water in a bowl or bucket. Dip a soft sponge or cloth into the soapy mixture and gently scrub the stained area using circular motions. 3. For more stubborn stains, a non-abrasive cleaner specifically designed for stainless steel can be employed. Apply a small amount of the cleaner to the stained area and utilize a soft cloth to rub it in. It is important to adhere to the manufacturer's instructions for the cleaner. 4. Thoroughly rinse the area with warm water to eliminate any soap residue. 5. To further restore shine and eliminate any remaining stains, a paste can be created by combining baking soda and water. Apply the paste to the stained area and allow it to sit for a few minutes. Then, gently scrub with a soft cloth or sponge. Rinse with warm water and dry with a clean towel. 6. To prevent future stains, it is advisable to consider using a stainless steel cleaner or polish. These products can aid in maintaining shine and making it easier to clean any spills or stains that may occur. It is essential to always test any cleaning product or method on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Additionally, it is important to avoid using abrasive materials or scrub brushes with harsh bristles as they can cause scratches on the stainless steel.

- Q: Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are generally resistant to abrasion. Stainless steel is known for its high strength and durability, making it less prone to scratches and wear compared to other materials. It has a smooth surface that can withstand friction and abrasion, making it suitable for various applications where resistance to scratches and wear is required. However, it is important to note that the level of resistance can vary depending on the specific grade and finish of stainless steel used.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets varies depending on the grade of stainless steel. However, most commonly used grades can withstand temperatures up to 1500-1600°F (816-871°C).

- Q: What is the maximum thickness of a stainless steel sheet?

- The specific grade or type of stainless steel being used can cause the maximum thickness of a stainless steel sheet to vary. Typically, stainless steel sheets can have a thickness ranging from 0.4 millimeters (0.0157 inches) to 100 millimeters (3.937 inches) or more. However, it's important to note that the availability of thicker sheets may be limited and can differ depending on the supplier or manufacturer. Furthermore, the composition and intended use of certain stainless steel alloys may impose different thickness limits. Therefore, it is always recommended to consult with a supplier or refer to the specifications provided by the manufacturer to determine the maximum thickness of the specific stainless steel sheet you require.

- Q: What is the difference between 304 and 316 stainless steel sheets?

- Both 304 and 316 stainless steel sheets are popular options for a wide range of uses because of their exceptional durability and ability to resist corrosion. However, there are some important differences to note. Firstly, the composition of these stainless steel alloys is the most noticeable distinction. 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. The added molybdenum in 316 stainless steel enhances its resistance to corrosion, particularly in chloride-rich environments like marine or coastal areas. Therefore, 316 stainless steel is often preferred for applications where exposure to harsh conditions or corrosive chemicals is anticipated. Secondly, the higher nickel and molybdenum content in 316 stainless steel make it more resistant to pitting and crevice corrosion, which can occur in stagnant or low-oxygen environments. This makes 316 stainless steel a better choice for applications that involve prolonged exposure to acidic or alkaline solutions, such as chemical processing plants or medical equipment. Thirdly, the higher molybdenum content in 316 stainless steel also improves its ability to withstand high temperatures. It can endure higher temperatures than 304 stainless steel, making it suitable for applications that involve exposure to heat, such as exhaust systems or boilers. Lastly, 316 stainless steel is generally more expensive than 304 stainless steel due to its higher alloy content. However, the added benefits and increased resistance to corrosion of 316 stainless steel may justify the higher cost in specific applications where performance and longevity are crucial. In conclusion, while both 304 and 316 stainless steel sheets offer exceptional resistance to corrosion, 316 stainless steel provides superior resistance to challenging environments, acidic or alkaline solutions, and higher temperatures due to its higher nickel, chromium, and molybdenum content. The choice between the two will depend on the specific application and the level of corrosion resistance required.

- Q: Can stainless steel sheets be used in high-pressure applications?

- Yes, stainless steel sheets can be used in high-pressure applications. Stainless steel is known for its strength, durability, and resistance to corrosion, making it suitable for withstanding high-pressure environments. It can be used in various industries, such as oil and gas, chemical processing, and power generation, where high-pressure conditions are present.

- Q: Can stainless steel sheets be used for food storage containers?

- Food storage containers can indeed be made from stainless steel sheets. Many people choose stainless steel for their food storage containers because it is durable, non-reactive, and resistant to corrosion. The stored food does not acquire any taste or odor, making it safe to store for extended periods. Moreover, stainless steel is easy to clean and maintain, ensuring optimal hygiene for food storage. Furthermore, stainless steel containers are often favored for their eco-friendly characteristics as they can be reused, thereby reducing the need for single-use plastic containers. In conclusion, stainless steel sheets are a dependable and appropriate option for food storage containers.

- Q: Stainless steel wire drawing without fingerprints, what principle?

- As for sandblasting, the surface roughness is higher than the wire drawing, and the stainless steel has no gloss (which makes the customer fail to see the stainless steel parts and sometimes lower the grade). Liquid blasting is recommended to achieve relatively better surface treatment results.Commercial kitchen experts completely hand, no copy paste. Please give favorable comments.

Send your message to us

400 Series Hot Rolled Stainless Steel Coils/Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords