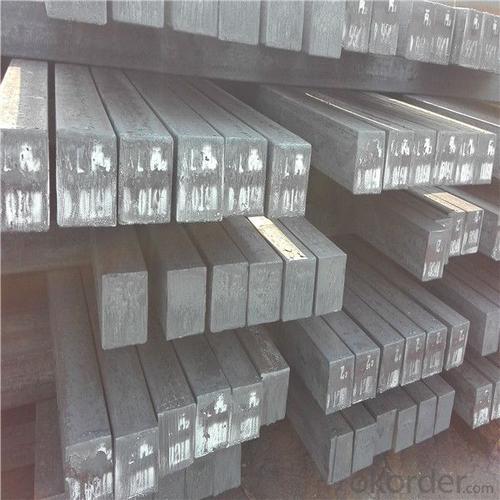

Square steel billet size from 120mm to 150 mm

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 29814 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets

have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also

known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: For example, screw plate (PU plate and manganese plate), carbon steel Primeton is what person rolling out?.

- Primeton Pu board generally refers to A3; carbon steel refers to the high quality carbon steel, such as No. 45 steel, 35 steel and so on;

- Q: What are the different quality standards for steel billets?

- There are several quality standards for steel billets which are used to assess the overall quality and suitability of the material for various applications. Some of the prominent quality standards include: 1. ASTM A615/A615M: This standard specifies the requirements for deformed and plain carbon-steel bars for concrete reinforcement. It covers billets used in the production of reinforcing bars with specific mechanical properties and dimensional tolerances. 2. ASTM A706/A706M: This standard outlines the requirements for low-alloy steel used in the production of reinforcing bars. It specifies the chemical composition, mechanical properties, and dimensional tolerances of the billets. 3. EN 10025-2: This European standard specifies the requirements for non-alloy structural steels. It covers billets used in the production of various structural elements, such as beams, columns, and plates. The standard defines the chemical composition, mechanical properties, and technical delivery conditions of the steel billets. 4. JIS G3112: This Japanese industrial standard covers steel bars for concrete reinforcement. It outlines the chemical composition, mechanical properties, and tolerances for billets used in the production of reinforcing bars. 5. GB/T 699: This Chinese standard specifies the quality requirements for carbon structural steels. It defines the chemical composition, mechanical properties, and technical delivery conditions of steel billets used in various structural applications. These quality standards ensure that steel billets meet specific criteria for strength, durability, and dimensional accuracy. Adhering to these standards guarantees that the steel billets are of high quality and suitable for their intended use in construction, manufacturing, and reinforcement applications.

- Q: What are the potential applications of steel billets in the agricultural aftermarket?

- The agricultural aftermarket offers a wide range of potential applications for steel billets. One important use in this industry is the manufacturing of agricultural machinery and equipment. Components such as plows, cultivators, seeders, and harvesting equipment can all be fabricated using steel billets. In the agricultural sector, machinery needs to be durable and robust to withstand the tough conditions of farming operations. Steel billets provide the necessary strength and toughness for tasks like tilling the soil or harvesting crops. Their high-strength properties make them perfect for handling heavy loads and rough terrain. Moreover, steel billets can be employed for constructing storage and handling structures. Steel buildings and structures are resistant to weathering, pests, and fire, making them ideal for storing agricultural products. By using steel billets for the main framework, these structures become durable and long-lasting. Another potential application of steel billets in the agricultural aftermarket is for fencing and livestock handling equipment. Steel fencing is commonly used to secure boundaries, contain livestock, and protect crops. By shaping and welding steel billets, strong and reliable fencing materials can be created. Furthermore, steel billets can be utilized in the production of irrigation systems and water management equipment. Efficient irrigation systems are essential for proper water distribution to crops. Steel billets can be used to fabricate critical components like pipes and valves, ensuring durability and longevity. In conclusion, steel billets have a wide range of potential applications in the agricultural aftermarket. From manufacturing machinery and equipment to constructing storage structures, fencing, and irrigation systems, steel billets offer the strength, durability, and reliability required in the demanding agricultural industry.

- Q: What is the difference between carbon three plants and carbon four plants?

- The mesophyll cells of carbon three plants are more dispersed, and there are no chloroplasts in bundle sheath cells. Photosynthesis is only carbon three cycle, and the utilization rate of carbon dioxide is low. It usually lives in temperate zone.Four carbon plant mesophyll cells arranged regularly, the formation of two circles of the "ring" and bundle sheath cells, bundle sheath cells have no chloroplast grana, photosynthesis has three carbon cycle and carbon cycle four, higher utilization rate of carbon dioxide, the general life in tropical and subtropical regions.The initial product of CO2 assimilation is not photosynthetic carbon cycle in three carbon compounds 3- phosphoglycerate, but four carbon compounds malic acid or aspartic acid plant.

- Q: Are steel billets used in the production of construction equipment?

- Yes, steel billets are commonly used in the production of construction equipment. Steel billets are semi-finished steel products that are typically hot-rolled or forged into various shapes and sizes. These billets serve as the raw material for manufacturing construction equipment components, such as beams, plates, rods, and structural parts. The use of steel billets in construction equipment ensures the durability, strength, and reliability of the final product, making it suitable for heavy-duty applications in the construction industry.

- Q: How are steel billets used in the manufacturing of medical equipment?

- Steel billets are an essential raw material used in the manufacturing of medical equipment. These billets are semi-finished steel products that serve as a starting point for various manufacturing processes. In the medical equipment industry, steel billets are utilized to produce a wide range of components and devices that are crucial for healthcare professionals and patients. Firstly, steel billets are often transformed into stainless steel through a process called stainless steel casting. Stainless steel is highly desirable in medical equipment manufacturing due to its excellent corrosion resistance, durability, and hygienic properties. It is commonly used in the production of surgical instruments, such as scalpels, forceps, and scissors, as well as implantable devices like orthopedic implants, pacemakers, and stents. Furthermore, steel billets are also used to manufacture medical equipment components through precision machining. These billets are machined into various shapes and sizes, allowing the production of parts like connectors, valves, brackets, and frames for medical devices and equipment. Precision machining ensures that these components meet the strict quality and dimensional requirements necessary for medical applications. In addition, steel billets are employed in the production of medical equipment casings and enclosures. These components provide protection and support for sensitive internal components, ensuring the durability and longevity of medical devices. Steel billets are often used to create casings for devices like X-ray machines, CT scanners, and MRI machines, as well as smaller equipment like infusion pumps and monitors. Overall, steel billets play a vital role in the manufacturing of medical equipment by providing the necessary raw material for the production of components, casings, and instruments. The inherent properties of steel, such as strength, durability, and corrosion resistance, make it an ideal material for medical applications. The use of steel billets ensures the production of high-quality, reliable, and safe medical equipment that is essential for the healthcare industry.

- Q: How do steel billets contribute to sustainable construction?

- Steel billets contribute to sustainable construction in several ways: 1. Reduced energy consumption: Steel billets are produced using electric arc furnaces, which require less energy compared to traditional steel manufacturing processes. This results in lower greenhouse gas emissions, contributing to the reduction of carbon footprint. 2. Recyclability: Steel is one of the most recycled materials in the world, and steel billets can be recycled multiple times without losing their mechanical properties. This reduces the need for new steel production, conserves natural resources, and decreases waste disposal. 3. Strength and durability: Steel billets have high strength and durability, making them an ideal choice for constructing sustainable buildings. Their structural integrity ensures long-lasting construction, reducing the need for frequent repairs or replacements. This helps to minimize waste generation and increase the lifespan of buildings. 4. Versatility: Steel billets can be shaped and formed into various structural components, allowing for flexibility in design and construction. This adaptability facilitates the construction of sustainable buildings that can be easily modified or expanded to accommodate changing requirements, reducing the need for new construction. 5. Resistance to natural disasters: Steel billets offer excellent resistance to seismic forces, hurricanes, and other natural disasters. This makes them suitable for constructing buildings in regions prone to such events, contributing to the resilience and safety of the built environment. 6. Reduced construction time: Steel billets enable faster construction due to their prefabricated nature. This reduces the overall construction time, minimizing disruption to the environment and nearby communities. Additionally, prefabricated steel components can be easily dismantled and reused, further enhancing sustainability. In conclusion, steel billets contribute to sustainable construction by reducing energy consumption, being highly recyclable, providing strength and durability, offering design versatility, resisting natural disasters, and reducing construction time. By incorporating steel billets into construction projects, we can create more environmentally-friendly and long-lasting structures, promoting sustainability in the built environment.

- Q: Can steel billets be used in the production of aerospace components?

- Yes, steel billets can be used in the production of aerospace components. Steel billets are often used as raw material for forging processes, which can be used to manufacture various aerospace components such as landing gears, engine parts, and structural components.

- Q: Are steel billets used in the manufacturing of industrial machinery?

- Yes, steel billets are commonly used in the manufacturing of industrial machinery. Steel billets are semi-finished products that are typically produced through a process called continuous casting. These billets serve as the raw material for various types of machinery, including heavy-duty equipment, construction machinery, and machine tools. Steel is a preferred choice for industrial machinery due to its strength, durability, and resistance to wear and tear. Steel billets are often used as the starting material for forging, rolling, or machining processes to create the specific components required for industrial machinery. These components can include gears, shafts, frames, brackets, and other structural parts. The high-quality properties of steel, such as its high tensile strength and excellent mechanical properties, make it an ideal material for withstanding the demanding conditions and heavy loads that industrial machinery is subjected to. Additionally, steel's ability to be easily welded and machined allows manufacturers to produce complex and precise parts for industrial machinery. Overall, steel billets play a crucial role in the manufacturing of industrial machinery, providing the necessary raw material to create strong and reliable components that can withstand the rigors of various industrial applications.

- Q: What are the main factors affecting the microstructure of steel billets?

- The main factors affecting the microstructure of steel billets include the composition of the steel, the cooling rate during solidification, the presence of impurities or alloying elements, and the heat treatment processes applied.

Send your message to us

Square steel billet size from 120mm to 150 mm

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 29814 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords