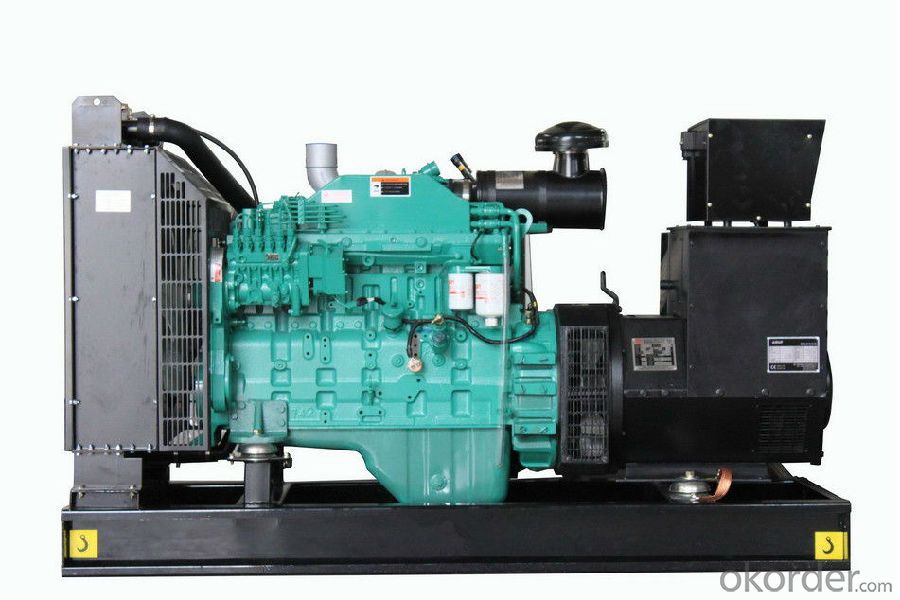

Soundproof Genset Diesel Generator , 35kw To 680kw Cummins Generator

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Detail:

1.Cummins Water Cooled Diesel Engine :4BTA3.9-G2,6BTA5.9-G2,KTA19-G3

2.Machinery or electronic governing

3.Original Stamford AC Alternator:UCI224E ,UCI274D,UCI274H

4.smartgen,Deepsea Control Panel with ats

Specifications:

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNRC30 | 20 | 25 | 24 | 30 | 4B3.9-G | ≤229 | 4 | 3.9 | 102*120 |

GNRC35 | 24 | 30 | 28 | 35 | 4BT3.9-G2 | ≤214 | 4 | 3.9 | 102*120 |

GNRC56 | 40 | 50 | 45 | 56 | 4BTA3.9-G2 | ≤215 | 4 | 3.92 | 102*120 |

GNRC63 | 45 | 56 | 50 | 63 | 4BTA3.9-G2 | ≤215 | 4 | 3.92 | 102*120 |

GNRC70 | 50 | 63 | 56 | 70 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC106 | 78 | 98 | 85 | 106 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC125 | 90 | 113 | 100 | 125 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC150 | 104 | 130 | 120 | 150 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC165 | 120 | 150 | 132 | 165 | 6CTA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC200 | 140 | 175 | 160 | 200 | 6CTA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC225 | 160 | 200 | 180 | 225 | 6CTAA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC275 | 200 | 250 | 220 | 275 | 6LTAA8.9-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC313 | 220 | 275 | 250 | 313 | NTA855-G1A | ≤206 | 6 | 14 | 140*152 |

GNRC350 | 250 | 313 | 275 | 350 | NTA855-G2 | ≤207 | 6 | 14 | 140*152 |

GNRC400 | 280 | 350 | 310 | 400 | NTA855-G4 | ≤208 | 6 | 14 | 140*152 |

GNRC413 | 300 | 375 | 330 | 413 | NTAA855-G7 | ≤206 | 6 | 14 | 140*152 |

GNRC450 | 320 | 400 | 360 | 450 | NTAA855-G7A | ≤206 | 6 | 14 | 140*152 |

GNRC500 | 360 | 450 | 400 | 500 | KTA19-G3 | ≤203 | 6 | 18.9 | 159*159 |

GNRC550 | 400 | 500 | 440 | 550 | KTA19-G4 | ≤203 | 6 | 18.9 | 159*159 |

GNRC605 | 440 | 550 | 484 | 605 | KTAA19-G6 | ≤204 | 6 | 18.9 | 159*159 |

GNRC625 | 450 | 563 | 500 | 625 | KTAA19-G7 | ≤204 | 6 | 18.9 | 159*159 |

GNRC700 | 500 | 625 | 560 | 700 | KTA38-G | ≤206 | 12 | 37.8 | 159*159 |

GNRC712 | 520 | 650 | 570 | 712 | QSK19-G3 | ≤206 | 6 | 19 | 159*159 |

GNRC800 | 580 | 720 | 640 | 800 | KTA38-GA | ≤209 | 12 | 37.8 | 159*159 |

GNRC825 | 600 | 750 | 660 | 825 | KTA38-G2 | ≤210 | 12 | 37.8 | 159*159 |

GNRC888 | 640 | 800 | 710 | 888 | KTA38-G2B | ≤210 | 12 | 37.8 | 159*159 |

GNRC975 | 720 | 900 | 780 | 975 | KTA38-G2A | ≤210 | 12 | 37.8 | 159*159 |

GNRC1075 | 800 | 1000 | 860 | 1075 | KTA38-G5 | ≤202 | 12 | 37.8 | 159*159 |

GNRC1375 | 1000 | 1250 | 1100 | 1375 | KTA50-G3 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1375 | 1100 | 1375 | 1310 | 1650 | KTA50-G8 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1650 | 1200 | 1500 | 1340 | 1675 | KTA50-GS8 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1675 | 1350 | 1688 | 1500 | 1875 | QSK60-G3 | ≤215 | 16 | 60 | 159*159 |

GNRC1875 | 1500 | 1875 | 1650 | 2063 | QSK60-G3 | ≤215 | 16 | 60 | 159*190 |

GNRC2063 | 1600 | 2000 | 1800 | 2250 | QSK60-G4 | ≤215 | 16 | 60 | 159*190 |

Genset Features:

1. Genuine Commins industrial diesel engine

2. Radiator 40°C max, fans are driven by belt, with safety guard

3. Genuine stamford. Leroy somer, marathonm, engga alternator

4. Choice of manual/auto and AMF control panels and protection systems

5. Digital auto-start panel

6. Anti Vibration Suspension Absorber

7. Dry type air filter, fuel filter, oil filter

8. 10-hour operation base tank

9.Mould case circuit breaker

10. 24V DC start motor and storage battery

11. 24V charge alternator

12. 24V batteries, rack and cable

13. Rippl;e flex echaust pipe, exhaust siphon, flange, and muffler

14. Comply with ISO and CE standards

15. All generator sets are gone through rigorous testing before beging released to the market place, including 50% load, 75% load, 100% load and all protection function(over speed stop, high water temperature, low oil pressure, battery charging fail, emergency stop)

Engine Features:

1. Genuine Cummins industrial diesel engine

2. Multi-cylinder in-line or veer engine, 4-stroke, direct injection

3. Naturally aspirated, turbocharged, water cooled or turbocharged with air intercooler

4. Machinery or electronic governing

5. Fuel injection pump

6. Electric motor starting system

7. Forged steel crankshaft, cast iron cylinder and replaceable wet type cylinder liner

8. Low discharge, and low fuel consumption

9. Installed conveniently and maintain easily

Alternator Features:

1. World famous brand AC alternator: Leroy Somer, Stamford, Marathon, ENGGA

2. Brushless, 4 poles, rotation magnet

3. IP21-23(NEMA1) enclose is standard for all industrial alternators

4. H class insulation system

5. AVR self-regulated, voltage regulation rate: ≤±1%

6. Simple installation and maintenance with easy access to terminals, rotating diodes and coupling bolts

7. Wide range of flange adaptors and single bearing disc coupling

8. Radio interference restraining accords with the stipulation of VDE0875-N and ISO8528

9. Moisture proof, sand-proof, dustproof, salt-proof and vibration-proof

Digital Control panel

Controller Brand: Smartgen, Deepsea,ComAp

Control Panel: English interface,LED screen and touch buttons.

- Q: What's wrong with the rotary roller

- It's possible that the roller card is dead You turn the drum manually and look at the ready

- Q: Is there any difference between motor and motor? A positive answer

- Electric motors include motors and generators. The general term for generators and motors is that they are conceptually different. However, certain motors, such as synchronous motors, are generally more used as generators, but can also be used directly as motors. Asynchronous motors are more used for motors, but by adding simple peripheral components, they can also be used as generators.

- Q: How does the motor stop

- Emergency stop switch: just for a switch, usually use red or yellow mushroom head button, plays the role of the emergency stop in control circuit, so that the emergency stop switch The first method, which is also the usual addition, sets a closed contact switch in tandem with the motor's contactor coil circuit. It is possible to power the contactor in the job, so that the electric motor that runs through the contactor is lost to the purpose of the emergency stop. Method 2: there are also some three phase power switch (motor power) with control contact. Use the emergency stop switch to control the three-phase power switch. The electric motors that are run by the contactor are lost to the purpose of an emergency stop. The first is gm, the second is more expensive. Supplement: Is three motor, there is a knife, and later began to work, I have a red emergency stop switch, I'd like to know more things, so pick up to press the machine stop? You can buy another contactor. Follow the first method.

- Q: Direct drive motor control mode

- The control board is the same as the general permanent magnet motor. The problem is you is to point to the need to control the motor start-stop, or to control the torque (your this kind of motor is primarily a torque motor), and you need to control analog or digital control. After certain, the circuit design is convenient. Need your motor driven load characteristics, work environment, such as the control response speed, accuracy, voltage, power, etc., and whether the high temperature, high humidity, high dust, high electromagnetic interference, etc., all of these have an effect on circuit design.

- Q: What is the difference between a three-phase asynchronous motor and a regular motor?

- Three-phase asynchronous motor cooling fan is fixed on the motor shaft, the same as the rotation speed of the motor, low frequency is run, the fan is running at low speed, the cooling capacity drops greatly, the heat generated by the motor can't send out, serious when burning motor. The structure and pressure capacity of the inverter motor are specially designed to accommodate high speed and high harmonics. Motor has the branch of general motor and frequency conversion motor, called main appearance is different from ordinary motor frequency conversion motor frequency conversion motor is packed with centrifugal fan forced cooling, this ensures the motor at low frequency and high frequency heat dissipation is good, and frequency conversion motor internal structure can adapt to the high frequency operation of specific working frequency range see nameplate. General motors generally allow only running under 50hz.

- Q: What is the difference between a general motor and a high-speed motor?

- Ordinary ac motor is restricted by the maximum synchronous speed, which can not reach high speed, dc motor (especially brushless motor) can achieve higher speed. The static balance and dynamic balance of high speed motor are high.

- Q: What are the characteristics of plateau motors? Why can't the general motors be used for plateau areas

- Compared with ordinary motor, plateau motor is adjusted for insulation strength, electrical clearance, temperature limit and anti-halo measures. 1, the increase in elevation causes the insulation strength to decrease: the insulation intensity should be reduced by 8 to 15% for every 1000 metres. 2, the breakdown voltage of the electrical clearance is decreased, so the need to increase the electrical clearance in accordance with the elevations. For high voltage motor, the initial voltage of the corona is reduced, and the anti-stun measures should be strengthened. The cooling effect of air dielectric decreases, the heat dissipation capacity decreases, the temperature rise increases, each increase of 1000M, the temperature rise should increase by 3-10%, so the temperature rise limit should be corrected. The high altitude is unfavorable to the dc motor. Pay attention to the choice of carbon brush material.

- Q: The problem of speed regulating motor and general motors

- With frequency converter, of course, will not shorten the life of the motor, ordinary motor frequency converter will be used to take, no problem at all, music fountain is with motor with frequency converter

- Q: The difference between B34 and B35 motors

- The motor is composed mainly of stator and rotor, which is related to the direction of force motion in the magnetic field and the direction of the current and the magnetic flux line. The operating principle of an electric motor is the effect of the magnetic field on the current, making the motor spin.

- Q: What is the difference between servo motor and general motors?

- The servo motor is called ac servo motor, ac synchronous motor. Common motors are commonly used to communicate asynchronous motors. The main difference is: 1, the distinction between closed-loop feedback and open-loop state principles; , this is also the biggest difference between ac synchronous motor through the backend sensor and encoder feedback speed, position, or torque reference value to form a complete set of drive, and real-time adjustment by the driver drive current value specified by the user to control motor rotation, dc stepper motor and asynchronous usually directly by the frequency converter or direct drive motor rotation, voltage regulator device will not external interference factors such as torque is too big, the heavy load to achieve the dynamic adjustment, so the former is more efficient than the latter, advanced, energy saving, accurate.

Send your message to us

Soundproof Genset Diesel Generator , 35kw To 680kw Cummins Generator

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords