Solar Silicon Wafer Carrier Suppliers - Mono Solar Cells 156mm*156mm in Bulk Quantity Low Price Stock 18.8

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

- Up to 20.0% efficiency, one of the highest performing mono crystalline cells on the market

- Three bus bars boosts current collection over the entire cell area, leading to higher fill factors

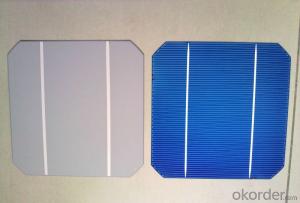

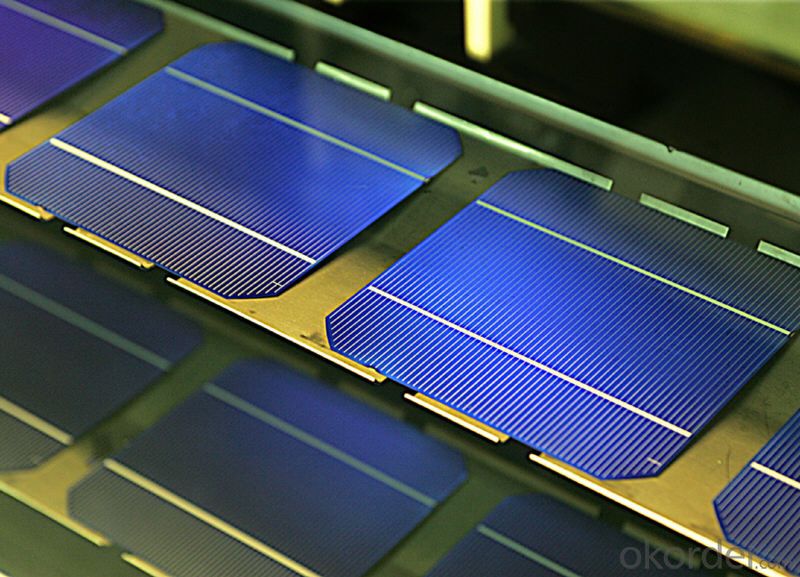

- Blue anti-reflecting coating allows more sunlight be captured and converted to electricity

- Finer, closer fingers improves charge collections for improved energy yield

- Lower light-induced degradation leads to greater power output over the entire module lifetime

- All solar cells are tightly classified to optimize output of module

- Maximum yield and longevity due to hotspot prevention

- Premium appearance results in a highly uniform and aesthetically appealing module

Specification

- Product Mono-crystalline silicon solar cell

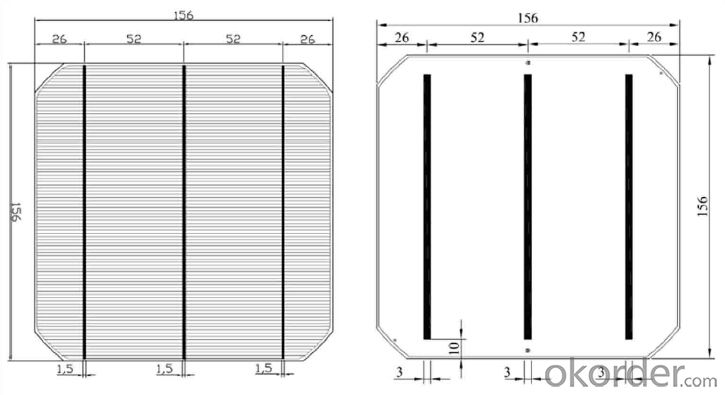

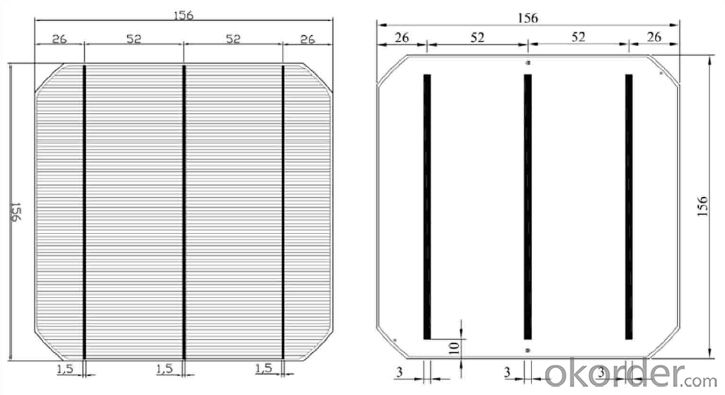

- Dimension 156 mm x 156 mm ± 0.5 mm

- Thickness 200 μm ± 30 μm

- Front 1.5 ± 0.1 mm busbar (silver)

- Silicon nitride antireflection coating

- Back 3.0 mm continuous soldering pads (silver)

- Back surface field (aluminum)

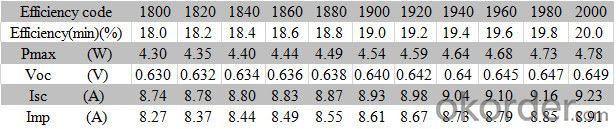

Electric performance parameters

- Testing conditions: 1000 W/m2, AM 1.5, 25 °C, Tolerance: Efficiency ± 0.2% abs., Pmpp ±1.5% rel.

- Imin : at 0.5 V

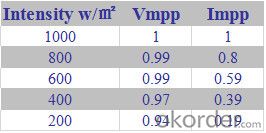

Light Intensity Dependence

Soldering Ability

- Peel Strength: > 1.0 N/mm (Pull soldered ribbon from busbar in 5 mm/s of 180°)

Dimension Figure

Quick Response

- Any time and anywhere, reply clients' email and solve all problems happen in the work at the first time.

- Remove clients doubts and offer the best solution at the first time.

- Give our clients the lastest news of the photovoltaic, update the newest stock informtion.

Production and Quality Control

- Precision cell efficiency sorting procedures

- Stringent criteria for color uniformity and appearance

- Reverse current and shunt resistance screening

- ISO9001,ISO14001 and OHSAS 18001,TUV Certificated

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

5. Q: Do you accept custom design on size?

A: Yes, if the size is reasonable.

6. Q: How can I be your agent in my country?

A: Please leave feedback. It's better for us to talk about details by email.

7. Q: Do you have solar project engineer who can guide me to install system?

A: Yes, we have a professional engineer team. They can teach you how to install a solar system.

- Q: How are solar silicon wafers tested for resistivity and sheet resistance?

- Solar silicon wafers are tested for resistivity and sheet resistance using a variety of methods. One common technique is the four-point probe method, where four evenly spaced probes are placed on the surface of the wafer. A known current is passed between the outer probes, while the voltage is measured between the inner probes. By applying Ohm's law, the resistivity and sheet resistance can be calculated based on the measured current and voltage values. Another method involves using a Hall effect measurement, where a magnetic field is applied perpendicular to the wafer's surface and the resulting voltage is measured. This allows for the determination of the resistivity and sheet resistance. These testing methods help ensure the quality and performance of solar silicon wafers in photovoltaic applications.

- Q: What is the role of surface passivation in solar silicon wafers?

- The role of surface passivation in solar silicon wafers is to reduce or eliminate surface recombination, which is the process by which charge carriers (electrons and holes) recombine at the surface of the wafer, leading to a loss of efficiency in solar cell performance. Passivation involves applying a thin layer of material, such as silicon nitride or aluminum oxide, to the surface of the wafer to create a barrier that prevents the recombination of charge carriers. This helps to improve the efficiency and overall performance of the solar cell by reducing the loss of generated electricity due to surface recombination.

- Q: How do solar silicon wafers contribute to the decentralization of energy production?

- Solar silicon wafers contribute to the decentralization of energy production by enabling the generation of electricity at the point of consumption. By converting sunlight into electricity, solar silicon wafers allow individuals and businesses to produce their own clean energy, reducing their reliance on centralized power grids. This decentralization helps to distribute energy generation across various locations, making the overall energy system more resilient, efficient, and environmentally friendly.

- Q: Why not use crystal silicon battery N type silicon, boron diffusion is difficult, or material difficult to do, or the principle of the problem?

- N type silicon wafer from the raw material price or quantity, and P type silicon wafer or some gap. This also led to the battery chip manufacturers for N battery has been in the laboratory stage, not mass production.Again, the P type battery is to take GA or boron, but the N type batteries into another material, I am not very clear, not engage in technology, huh, huh, huh, huh.The above information, I hope to help you.

- Q: What is the meaning of the wafer (100), the crystal orientation index or the crystal plane index?Also (1100 and (111) which direction and angle should be cut?

- It's the wrong markIt should be pointed outCrystal growth direction

- Q: Are solar silicon wafers affected by humidity?

- Yes, solar silicon wafers can be affected by humidity. High humidity levels can cause the surface of the wafers to become contaminated or corroded, reducing their efficiency and performance. It is important to protect solar silicon wafers from excessive moisture and maintain appropriate environmental conditions for optimal operation.

- Q: How is the reflectivity of a solar silicon wafer reduced?

- The reflectivity of a solar silicon wafer is reduced through the application of an anti-reflective coating. This coating consists of a thin layer of materials that help to minimize the amount of light reflected off the surface of the wafer, allowing for more efficient absorption of sunlight and increased energy conversion in solar cells.

- Q: What is the role of back surface field (BSF) on solar silicon wafers?

- The role of the back surface field (BSF) on solar silicon wafers is to reduce the recombination of charge carriers (electrons and holes) that occurs at the back surface of the wafer. By creating a high-doped region at the back surface, the BSF helps to enhance the efficiency of the solar cell by preventing the loss of generated charge carriers, thus improving the overall conversion of sunlight into electricity.

- Q: How does the efficiency of a solar silicon wafer change with shade?

- The efficiency of a solar silicon wafer decreases significantly with shade. Shade obstructs the direct sunlight that is necessary for the wafer to generate electricity. When even a small portion of the wafer is shaded, it can cause a drop in overall efficiency. This is because shade reduces the amount of light reaching the wafer's surface, leading to reduced power output. Therefore, minimizing shade and ensuring maximum exposure to sunlight is essential for optimizing the efficiency of a solar silicon wafer.

- Q: What is the role of solar silicon wafers in reducing the digital divide?

- Solar silicon wafers play a crucial role in reducing the digital divide by enabling the production of affordable and accessible solar panels. These panels can harness solar energy to power electronic devices and provide electricity to remote and underprivileged areas that lack access to reliable power sources. By reducing dependency on traditional power grids, solar silicon wafers contribute to bridging the digital divide by bringing electricity and connectivity to marginalized communities, enabling them to access digital technologies, educational resources, and participate in the digital economy.

Send your message to us

Solar Silicon Wafer Carrier Suppliers - Mono Solar Cells 156mm*156mm in Bulk Quantity Low Price Stock 18.8

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords