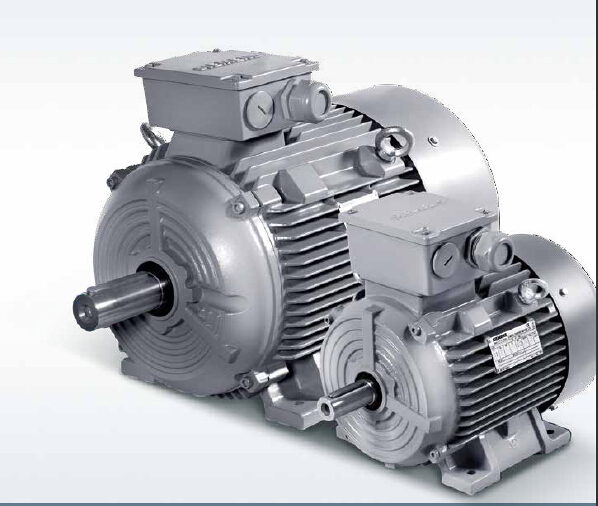

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: i need to use an electric motor and i need to know how to change it to dc

- Hold on a minute. If you're thinking of running an AC electric motor on DC, forget it. It won't work. If the power available is DC, you need a DC motor that runs on the voltage you have available. Most common, single-phase, AC motors require 120 volts. You'd better regroup and reconsider your strategy.

- Q: the foreign motor shows 380 volts 3 phase. I have 480 volts 3 phase

- If you use a variable frequency drive to reduce the frequency to 50 Hz, the drive terminal voltage should also reduce in proportion with the frequency 480(50)/60= 400.Check the v f drive terminal voltage, if it is 400 volts only, your motor should work without overheating.

- Q: Which one uses magnets for its rotor and which one uses a wire loop i'm confused

- Synchronous motor has a rotor (the non-stationary part of a rotary electric motor) spinning, that is with coils (wire loops) which produces a magnetic field which drives it. Contrast this with an induction motor, which must slip in order to produce torque. An asynchronous motor (or induction motor) is an ac motor where power is supplied to the rotor by means of electromagnetic induction. This converts electrical power to mechanical power in its rotor (rotating part). Hope this helps...

- Q: what determines the speed of electric motors?

- The amount of current applied to the magnets in the motor.

- Q: if there is a 1 kwh DC motor , can it works by using 1 kwh AC generator connected with converter or not?

- Each of the 3 units has some losses, so the DC motor can only work with light loads.

- Q: How to estimate the HP of an AC traction motor basing on continous rating when V rms and I rms along with RPM has given

- Revised later to correct my own confused reading of the question. It is not clear what the given values represent. Is the current a measured value under operating conditions or a value given as the rated current? You can not accurately calculate the rated or actual output power without the efficiency and power factor. You can not even estimate the actual output power without knowing the rated output power. The power factor at rated load will be similar to efficiency estimated for various power ranges in another answer. At less than rated load, power factor and efficiency are less that they are at full load with zero efficiency and nearly zero power factor at no load. If the given current is the rated current, the input is 1500 X 200 X 1.73 = 519 KVA. If you estimate the efficiency and power factor at 0.95 and 0.85, 519 X .94 X .83 = 419 kW output or 419/0.746 = 562 Hp. The best way to estimate rated power from rated current is to look in motor catalogs and match up the current rating with a listing for a similar motor. Catalog data is also useful for accurate estimation of actual load power from actual load current. Re further details: The above paragraph gives an estimate calculation based on continuous ratings for voltage and amps based on 3-phase RMS values. If you know standard power ratings for the type of motor, estimate based on the standard power value nearest to the calculation results; for example 500, 550 or 600 Hp.

- Q: I have a 2001 BMW 325i..the air conditioning completly went out about 2 weeks ago, nothing would work. I took it to a repair shop m,y buddy owns (so i know he didnt cheat me) and they said it may be the blow motor, so they fooled around with it and it started working after 5 minutes of messing with it it automatically came on and started working. They said the antifreeze was low so they filled that up also and I was on my way....about 3 days of the air conditioning working fine, i came out side and id had the ac on high went i turned the car off and it was still on....now even if the cars off the air still blows on high, if you try to turn the air off or turn it down its still on....what could it be??????

- bad ac switch. its not sending the right signals or maybe no signal

- Q: a motor that runs on ac and dc?

- Mostly, if they have a lot of power in a small package (especially for rotary speed), but are used only sporadically. They often are a bit noisy. If they have a speed control, then they could be universal.

- Q: hyundai Elantra 2000My AC blows cold and hot just fine, but It rarely blows at the max power for whatever setting I have (I keep it on 4, the highest setting). Sometimes I have to hit it to get it started. here's the funny part, If I make a LEFT turn on the road, my AC will crank up to full proper blast until I come out of the turn. If I make a RIGHT turn, it shuts off completely and only starts again when Im out of the turn or if I kick it after. Anyone know how to fix/clean a blower motor? I really dont want to have to replace it. Thanks.

- It sounds as though your blower motor resistor is bad. When you jar the dash or make a turn, it might be making connection for a few minutes. Try the other speeds, and see if those speeds are ok. If you only have this problem on the high setting, it is most likely the blower resistor shorting out internally.

- Q: i have an old electrical blacksmith blower. the motor doesn't include a built in transformator. it just needs an it has an input of 3 Amp and 28 Volt.but i don't know if it's Alternating or Direct current.how do i test this?

- Input is AC, output is DC

Send your message to us

Siemens ILE0001 Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords