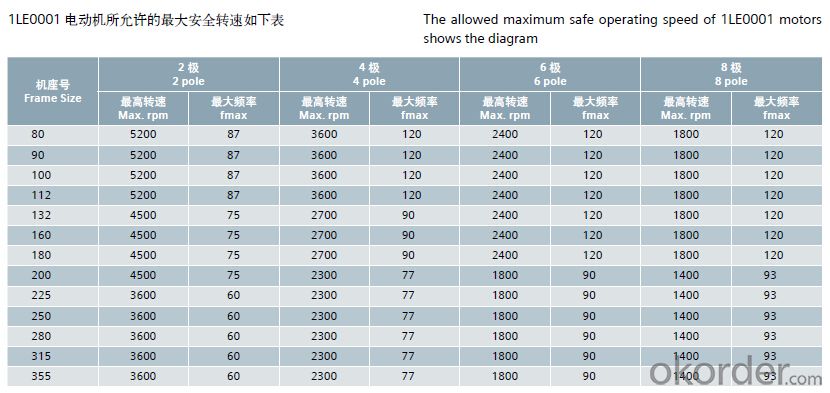

Siemens High Low Voltage Motor ILE0001 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q: What's the difference between an AC motor and a direct current motor?

- The continuous use of DC motor is short, for example: DC motor in use for 60 minutes, 10 minutes to rest, let the motor off heat, unstable power output, power consumption is based on the weight of the user to decide, but less noise.AC motor used long, can be dozens of hours of continuous use, and the power output is stable, the noise is a little larger.

- Q: I asked this question earlier but wasn't as specific I have a 2000 Lincoln Navigator AC was fine yesterday I went to use my AC today and the blower motor wont turn on the AC pump works fine but the blower wont even kick on for the heat I tested all fuses for it there all good I unplugged the blower tested the plug and it had no power I'm pretty car smart so if sombody could please help me out to get it working again I appreciate it I am aware that the heat/cooling head unit could of just went bad but the chances of that over night seem slim

- first, did you test each spot for available voltage while the car was running with AC switch on? if you did it all while the car was turned off you'll get false readings, keep looking through the whole circuit and once you find available voltage in between that n where there is no voltage you'll have to visually find the open, another problem could be that you have a refrigerant leak somewhere, the ac refrigerant can leak out in one day if it's bad enough and if you have no refrigerant in the ac system then the ac magnetic clutch won't even turn on because the pressures aren't high enough so you would get no voltage in the AC circuits because pressures aren't high enough for the ac system to kick on

- Q: Hey guys! I need your help.... I know just one point that DC motor can control speed even with load but AC motor can't. I want more points...... could u help me???? It would be gr8 if u could tell me the name of the site from where i can get some info. about this.......Thankyou in advance!

- Advantages Of A Dc Motor

- Q: hi, i am doing my final yea project and i have decided to build a electric can crusher, i have performed some laboratory test and it take around 3000 N force to crush some cans. now i need to choose my E.motor and not sure which one to choose, and also not sure what gear ratio i need for my sprokets.thanks

- Easy man,,,,,,,, just go for a motor which has an power greater than 3000N or you select a low power motor and increase the gear ratio..... come on man do it........

- Q: Can the voltage regulating module be used as AC motor speed regulation?

- Want to control motor speed, only changing voltage frequency on the stator can (with more of a V/F control, change the frequency corresponding to the change of voltage amplitude), change the voltage regulator will not only change the frequency, voltage, it will only change the motor torque (the size of the voltage will not change, otherwise it will cause the stator coil current is too large; for example, if you burn the motor) with voltage regulator voltage applied to the motor will change the speed two times, will have little change but far less than the two times. When using the voltage regulator experiment, do pay attention to the rated voltage of the motor, otherwise it may cause permanent damage to the motor!

- Q: I have a window unit AC. Lately, even when I turn it completely off, the motor runs sporadically. It does not blow air when it does this. It didn't do this until the past few weeks (I've had it several years). It continues to work well other than this.. ols well and everything.

- if its real old it could be the switch is shorting out. try to turn it off and wiggle the switch to see if it runs. Or if it is running try to wiggle the switch to see if it shuts off. Another possible problem could be that the outlet is wired backward and the unit is hot all the time. U would need a outlet tester to find that out or a Volt meter.

- Q: Does anyone know of any websites to do this? I have an old 110v AC motor from an old vacuum.

- You try to modified the rotor as a permanent magnet rotor connect a suitable bridge diodes in out put winding get the DC..Best of luck .Other method you have to modified with extra winding with excitation may not suitable expensive..

- Q: Main structure of AC motor

- An electric motor consists of two basic parts: stator: Base: usually made of cast iron or cast steel. The utility model is used for fixing the iron core and the stator winding, and the front two rear end covers support the rotor shaft, and the outer surface of the rotor shaft is provided with a radiating rib.

- Q: I know the brushed are less magnetic interfered, higher efficient, etc. But, how the DC and the AC of the brushed type different? Sincerely.

- AC motors use slip rings and brushes . AC current is changing direction at 60Hz. The slip rings maintain electrical contact with the coil while allowing the coil to rotate. Slip rings to do not provide any mechanical switching of the conductor path (wiring) DC motors use a communtator and brushes. DC current is unidirectional, alway flows in the same direction. The commutator also allows the coil to rotate while maintaining electrical connection but with an important difference. A commutator will perform switching based upon the angle of rotation. A communtator is a series of individual copper strip pairs. Where each individual strip in a pair is connected to one end of a coil. The commutator strips are electrically isolated from one another. As the coil rotates the commutators conductive strips pass under the brushes. DC current is applied to the coil in one direction and as the coil winding of the motor rotates the communtator bars (strips) connect to pass DC current in the opposite direction in the coil. In essence a commutator causes the DC current to switch back on forth in the motor winding of the armature(shaft). Thus by defintion The DC motor has AC in its armature windings when the motor is running. The frequency of this AC is a function of RPM and the number of poles....

- Q: I work on cellular radios and we always use a rectifier to convert the AC to DC. It seems like we should be able to use AC to run the equipment. What is the specific reason we can't?

- we can but we don't want, it may cause instability and unwanted performance. for example if a chip needs source voltage 5 volt and it is ac then in some voltages (if it is AC) it won't work cause it goes from -5 to 5 with a stanadar frequency but you need all the time 5V. Also the behaviour of the inductors and the capacitors will be uncertain. But the reason that the AC is used in the jack is that it's transported more easily in big distances in unlike the DC

Send your message to us

Siemens High Low Voltage Motor ILE0001 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords