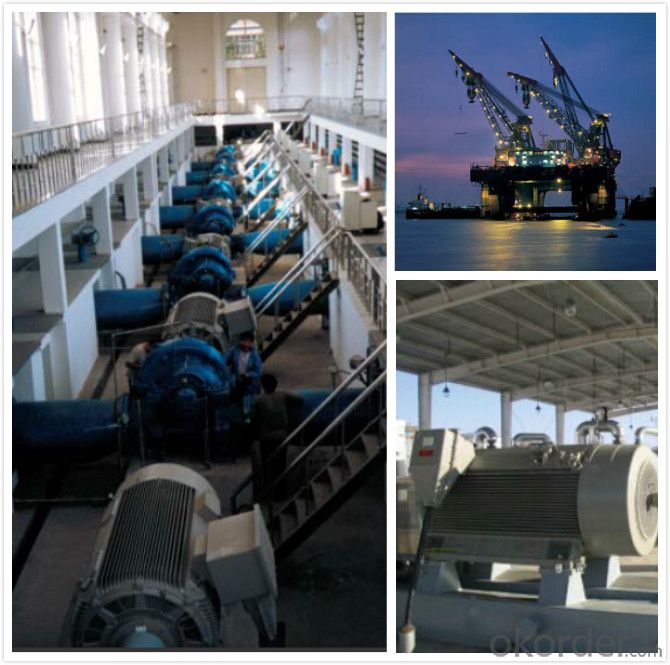

Siemens 1LA8 High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q: Why asynchronous motor AC excitation, rather than DC excitation?

- An induction motor is a kind of AC motor based on the air gap rotating magnetic field and the induction current in the rotor winding to generate electromagnetic torque, so as to realize the energy conversion. As the rotor winding current is induced, so there is a certain difference between its speed and synchronous speed. Asynchronous motor and synchronous motor difference: synchronous motor running normally, the revolution is fixed, not because of changes in load changes. In normal operation, the revolution of the induction motor is not fixed, but it varies slightly with the change of the load. Synchronous motors are complex circuits with reversible energy (motors and generators are interchangeable theoretically) and are used as generators

- Q: Boyfriend is trying to repair our window AC unit. He says the problem is the fan motor (not the compressor, etc). It'll run and cool the room for a little while (20-30 minutes maybe) and then it will die. We can wait and turn it back on, but it always dies after a little while. What exactly could be wrong with the fan motor?

- will you do us a favor, and post pictures of him changing it on this site. And tell him hes gotta do it without breaking any plastic parts and cant bend any of the coils when he takes the blades off both sides of the shaft. And no swearing when he puts the clip back on the squirrell cage. Actually you can unscrew and GENTLY move both coils out of the way, but dont bend the freon lines too much, just enough to get to the blades.

- Q: its wired to go cw but either way you wire it ,the motor change direction each time it stops

- sounds like either the start windings in the motor is going bad..or the start switch in the motor..or the capacitor is going bad...

- Q: I'm not going to lie and say I know a whole lot about the physical side of electronics, so I'll just straight out and ask if I could run a stepper motor I stripped out of a scanner on a series of D batteries (adding up to 12v, the motors operating voltage)

- they run on DC, and yes, you can run one on batteries. If you're not fussy, DC supplies are all around. You have one in the scanner. .

- Q: If the current is 45 amperes under this condition, calculate the power factor, reactive power, and reactive kilovolt-amperes

- You didn't state whether it was a 3-phase or single-phase motor. At 8.8kW input, the equivalent input horsepower HP is: 8.8kW/(.746kW/HP) = 11.8HP input equivalent. I say input equivalent because horsepower normally means mechanical output power. Around here, that would require three-phase power, so assuming it is operated at a nameplate voltage rating of 230V 3-phase, the following calculations can be made: input kW = 8.8kW (given) input kVA = 45A x .230kV x 3^(1/2) = 17.93kVA power factor PF = (input kW) / (input kVA), or PF = 8.8 kW / 17.93 kVA = 0.4908 = 49% The reactive factor RF = sin ( arccos ( PF ) ) RF = sin (arccos ( 0.4908) ) = 0.8713 = 87% Reactive power = RF * kVA = .08713 x 17.93kVA = 15.6kVAR Reactive kVA = 15.6 kVAR Check: kVAR = ( kVA^2 - kW^2 ) ^ (1/2) kVAR = ( (17.93kVA)^2 - (8.8kW)^2) ^(1/2) kVAR = 15.6 kVAR it checks.

- Q: What is the power factor of single phase capacitor start motor while running under load or without load. Some motors have capacitor permanantly connected in series winding. What power factor of these motors?

- Yes, there is a power factor for motors. For any AC fed electrical device, unless it is purely resistive (which motor is not), there are power factors. Because motors are inductive, it has reactance components. By having reactive components, the rise of voltage is not in synch with the current - which causes apparent power consumption differ from effective power consumption. This is the power factor. Exactly what it is for your motor, there is no way for me to tell. The capacitor is used (required) for AC motors for single phase to create a 90 degree off phase signal, so the second winding develops magneticism at the different timing from the first. Without this phase differential, the motor won't turn. On 3 phase motors, this is not necessary, as you already have 3 phase that are 120 degrees off from each other. The only way to get an answer to your question is to look at the spec for your motor.

- Q: I know the brushed are less magnetic interfered, higher efficient, etc. But, how the DC and the AC of the brushed type different? Sincerely.

- AC motors use slip rings and brushes . AC current is changing direction at 60Hz. The slip rings maintain electrical contact with the coil while allowing the coil to rotate. Slip rings to do not provide any mechanical switching of the conductor path (wiring) DC motors use a communtator and brushes. DC current is unidirectional, alway flows in the same direction. The commutator also allows the coil to rotate while maintaining electrical connection but with an important difference. A commutator will perform switching based upon the angle of rotation. A communtator is a series of individual copper strip pairs. Where each individual strip in a pair is connected to one end of a coil. The commutator strips are electrically isolated from one another. As the coil rotates the commutators conductive strips pass under the brushes. DC current is applied to the coil in one direction and as the coil winding of the motor rotates the communtator bars (strips) connect to pass DC current in the opposite direction in the coil. In essence a commutator causes the DC current to switch back on forth in the motor winding of the armature(shaft). Thus by defintion The DC motor has AC in its armature windings when the motor is running. The frequency of this AC is a function of RPM and the number of poles....

- Q: I'm trying to build a homemade wind generator and I'm having all kinds of trouble...I know DC motors are the easiest to work with but AC motors are the easiest to come by, at least they have been for me thus far. I have tried multiple motors some with capacitor start and a couple without. All I get out of any of them is NOTHING! LOL It's so irritating. I have a full wave diode to convert the AC to DC and I have tried all the motors both with and without the diode and that max I can get out of them is something like .02 VDC or AC it doesn't matter what I do I still get the same results. I know the meter is fine cause I have used it on little hobby motors and it read their voltage just fine. The motors do work I've plugged them in before and they run fine. Any ideas on what I'm doing wrong and thing I should try would be greatly appreciated. I'm not sure if the motor with capacitor start is a usable type for what I'm trying to do. Just came across a website a while bck that said yes Thnx

- I do not understand what you are doing. if a wind generator is to be made, then the wind turbines should rotate and this rotation should be coupled to the generators and the generator will generate voltage and if sufficient voltage is generated (In US it is 110 V AC) and if the have the capacity to have enough power then they will run your AC motors or if you DC motors then the voltage and power generated should be equal or more than the motor's driving power. If you do not generate any power/voltage or produce very little power then the motor will not run and will load on the generator and the voltage will go down to zero. Are you connecting the motor as generators and coupling them to the wind generator? then I very much doubt whether they work. If they are synchronous motors, then they can run as generators and vice versa. So everything properly and consult an electrical engineer. There is a chance that you may get electrocuted.

- Q: ( Just the basics? )Why does the armature spin continuously in both?I really do not understand , why does the current alternate in an AC generator anyways?how do the slip rings work?

- The principle of operation of a dc motor is that current through a coil of wire forms an electromagnet. Lets assume the electromagnet is formed in the rotating part of the motor (rotor). that gets its power through the split rings and carbon brushes. The fixed portion of the motor(stator) is a powerful magnet. The north pole of the electromagnet will be attracted to the south pole of the fixed magnet and cause the rotor to turn. As the magnets get near alignment the split rings(commutator) remove power from that coil, and apply power to another coil that is physical wound at an angle such its north pole will continue the rotation. the rotor will contain many coils each with a pair of contacts in the commutator.

- Q: Hi i am looking for a company that makes hollow shaft ac motors , it is american company that is called US , but i cannot seem to find it anywhere , i tried googling for it but obviously the brand name ( US ) isvery common that i get a lot of results that i am not looking for , can any one help me with this brand , if there is a website or something for them i woud really appreciate it

- Go to yahoo. Type in hallow shaft ac motor... And you will find it

Send your message to us

Siemens 1LA8 High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords