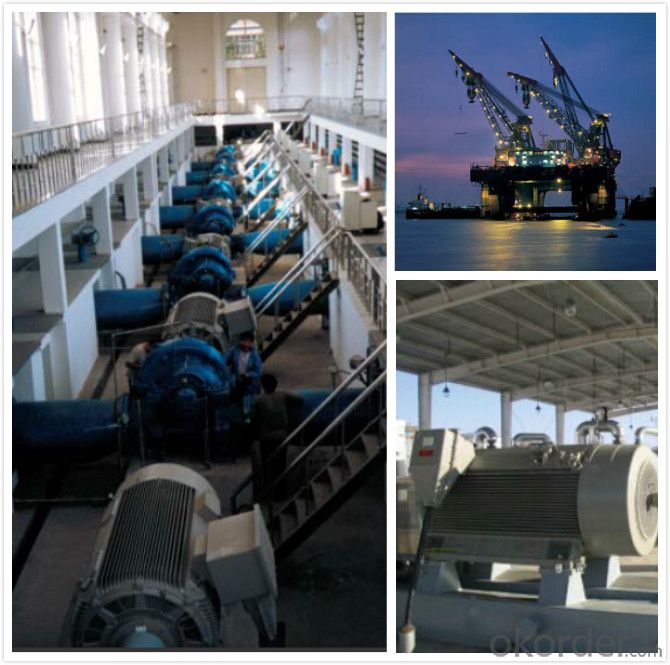

Siemens ILE0001 Series High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q: Isn't the starting winding symmetrical? If it's symmetrical, it's also an alternating pulsating magnetic field, how can you drive the rotor?

- 1. did not start winding, the rotor twist of the hand is because you can start to a rotating direction of the rotor, so that the main winding can rotate in a direction that, as long as you manually start after the rotor can not stop, because the main winding rotor will provide energy.2. the starting winding is symmetric, also accounted for 1/2 circle, starting winding due to capacitor phase shifting function and produce, in the electric cycle and the main winding is 90 degrees (like 90 degrees in advance), such changes in the magnetic field generated by the magnetic field have successively, have a fixed rotation direction, thereby according to a rotation direction of the rotor, the motor does not start winding and does not move because the main winding is 180 degrees and polar conversion, the rotor can be considered both left forces can be considered to be the right power, so the rotor is buzzing motionless.

- Q: Say i have a 400hp ac 3-phase motor.speed is given as 3575 rpm.Does this mean that if left to run on it's own (with 60hz and the related voltage etc) or unloaded it would produce 3575rpm? and the torque would just be power/speed?if this is the case, does this mean that if i loaded the motor with double this torque its speed would half?Basically i'm trying to figure out how to work out the performance characteristic of a motor for different loads given the basic manufacturers data.thanks...

- This is a 3 phase induction motor. The field rotates at 3600 RPM's and the squirrel cage rotor rotates at 3575 RPM at full load. The slip speed is the difference of field rotation and squirrel cage rotation speed. The slip speed causes a current to be introduced into the squirrel cage rotor which in turn generates the magnetic field in the cage that causes it to rotate in the first place. At no load the slip speed drops so the rotor spins at nearly 3600 RPM.

- Q: New blower motor on 7900 coleman gas furance will not turn my fan unless i push the fan with my finger to ge?

- I presume the motor is an AC motor. It almost certainly uses a start capacitor to provide the push you are giving it with your finger. The capacitor itself may be bad, but it is even more common to have a bad start contact in the control circuit. The capacitor is only connected long enough to get the rotation going. The first source should help.

- Q: hey i have four questions for yas most apprieciated if you can help!!!Question 1Where does the energy that makes the DC electric motor work originally come from?Question 2What difficulties would you have measuring the current flowing through a DC electric motor when it is operating?Question 3Please Explain how you would calculate the resistance (in ohms) of a DC electric motor circuit.Question 4PLease name as many appliances that have electric motors in themplease and thank-you if ya answered!!! PEACE OUT :D

- 1. The power for a DC motor can be from different sources. It may come from a battery such as small toy trucks or the blower motor on your car. It may come from AC power through rectification. Such as in many industrial applications. 2. It is done commonly in troubleshooting. I personally would use a clamp on ammeter. Simply put it around one of the wires going to the motor and read the readout on the meter. Smaller motors this would be harder. You could also use a regular ammeter by placing the ammeter in series with the motor but that would require some wiring. 3. To calculate the resistance in ohms of the DC motor you would need to know a couple of things. First of all what is the voltage applied to the motor. Second of all, how much current did you measure in step 2. Now use Ohm's law where R = E/I. R is the resistance in ohms, E is the voltage and I is the current. 4. Many appliance have electric motors however, not many household appliance would use a DC motor because it would take additional equipment to convert the household AC to DC and since there are small AC motors readily available this is not done. Washers and Driers have a drive motors and timer motors. A microwave with a turning table would have a motor. Blender, refrigerator, furnace, mixer, garbage disposal, can opener....too many to hit them all. Now, some smaller household electronics such as computers, video games, vcr's dvd players, walkman's, etc. would have DC motors.

- Q: Specifically for a single phase AC induction motor...I'm having trouble wrapping my head around the concept of an overloaded motor drawing more current. Since current draw increases when electrical resistance decreases, then how does a motor with bad bearings increase current draw? I realize the motor needs to do a lot more work, but how does the extra mechanical resistance caused by bad bearings translate into a decrease in electrical resistance, which causes higher current draw? Is there a power equation factor here that I'm not taking into consideration?

- Hello Sanchez, When electrical energy is given to any motor, the mechanical output is always less than desired. This is because there are always some windage and frictional losses. You will understand from the following description: Motor input in stator can be divided into Stator Copper Iron losses and Rotor input. The rotor input can be further divided into Rotor Copper loss and Mechanical Power developed or Gross Rotor output. This Gross rotor output can be divided into Windage and friction loss and Rotor output or motor output. So in your case, even though the motor electrical resistance is not varying, but due to bad bearings, the windage and friction loss increases tremendously, leading to heating of motor. Since induction motor rotates at high speed, these losses will be very high, will lead to burning of motor, if the bearings are not replaced quickly.

- Q: No sound no spark or smoke. Does it need a start capacitor I wonder now?

- You wired it wrong.

- Q: An AC motor is supposed to be a constant power motor. Suppose it is running a constant torque load at a particular speed. Suppose now the voltage is reduced, which should cause it to settle down at a lower speed supplying the same torque as per the new torque speed characteristic. Consider the electrical side. Higher slip will cause more current to be drawn that too at higher pf, which should maintain the power justifying the above theory. But on the mechanical side the new output power Torque x speed is supposed to be lesser now as speed is less now. Could anyone explain this contradiction?

- The speed of an induction motor is almost independent of the torque, and in a synchronous motor it is totally independent of torque. So if a motor is loaded at a constant torque and the voltage changes the power remains almost the same and the current goes up. This means the motor acts like a constant power machine under these conditions.

- Q: can you connect a 1/4 hp ac motor directly to the output of ac from a windmill or turbine?

- I imagine it can be connected, but the output of the ac motor will be determined by the output of the turbine at the time. If the turbine is under-supplying power, the motor will under-perform; if the turbine is oversupplying you risk the ac motor burning out. Referring to the specifications of the turbine will help determine if its a good idea to connect it directly. I believe most windmills are designed to limit rotational speeds for safety and durability reasons - so such turbines do tend to have an upper limit of sorts (and i think this can be manually changed at that - angle to the wind etc).

- Q: Which motor has a great torque when the motor is under DC at the same power?

- Ordinary (squirrel cage) AC motor starting current and start torque is small, it is much better than the start of DC motor, which is a common sense.

- Q: Can any 220V AC motors be reversible?

- The four lines can be reversed by changing the direction of the starting winding.By comparing the resistance size, generally speaking, the starting winding resistance is greater than the main winding.The starting capacitor has no direction, so there is no change in the direction of the motor by changing the direction of the capacitor.

Send your message to us

Siemens ILE0001 Series High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords