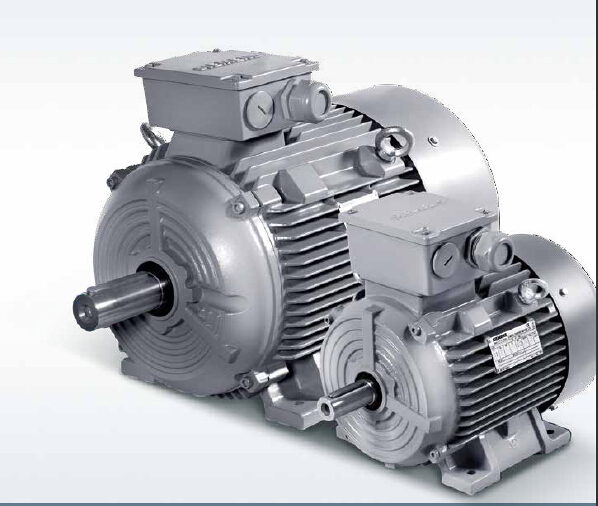

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: what is the amps of a normal ac motor?

- Depends which motor. Bigger ones will draw more.

- Q: Please elaborate the formula or technique of speeding up the motor used in sirens...?

- The okorder /

- Q: i would like to use dc motor against 10hp Ac motor for my 100 ton power press

- None of this makes sense. If you want a 100ton press, you need to use Hydraulics. To use motors, would require very large, high voltage motors, or very large gears.

- Q: please help i am doing an assignment on electrictric motors and have no clue what this answer is.. the question isExplain where the force comes from that makes the elecrtic motor work!!!! somebody?

- In a DC motor power is fed usually to the internal shaft with brushes, there are two or more magnets on oposite sides of the caseing. the power goes through a winding or coil that creates a magnetic field. pushing the coil away from one magnet and towards anouther with the opposit charge. As it spins the brush looses contact with a contact plate and then makes contact with anouther contact plate for a different winding, and the process happens again, as the shaft turns different windings are energised keeping the rotation going. In an AC motor works about the same however an AC motor makes use of the alternating direction of current to create and colapse magnetic fields that push then pull the rotor around. SO in answer, it works of magnetism, specifically electromagnets.

- Q: Do we need constant frequency and constant voltage for AC motor forrunning it at constant speed?

- The Voltage and the Frequency are varied to adjust the speed. This method is incorporated in a Variable Frequency Drive (VFD). If you want to run at a constant speed it is like any other motor. Variations in voltage, frequency and load cause speed variations, so a control system is required to compensate for these effects. In principle, a tachometer is used to measure actual speed, and the difference between this and the desired speed are used to adjust the speed, using a VFD.

- Q: I have a 90v DC electric motor I would like to run with 110v electricity. It was running off 110v when it was inside a wheel balancer. The motor came out of a wheel balancer and I need it for a specialized fan application. What kind of converter do I need to not only run it with 110v, but also make it variable speed? Any suggestions?

- If you are going to use a pulley to wind up the string, the motor polarity doesn't matter, so all you need is a twin flex from the mains adapter, it doesn't matter which way you connect the leads to the motor or the adapter. If your adapter doesn't have a twin flex coming out of it you can buy a multiconnector for DC power supplies and cut off the single power jack at the end of the lead before using the bare ends to connect to the motor. The multiconnector should have one plug which fits the adapter socket.

- Q: How to synchronize two ordinary AC motors?

- I'm afraid it's not easy. Ordinary AC motors are asynchronous motors. Two identical motors, when the load is exactly the same, and at the same time, it is possible to synchronize, but this synchronization is prone to damage. Personal view, for reference only.

- Q: I've been searching for a while but can't seem to find anything on it, I'm trying to design a system that will incorporate a servo motor (8kW of power) and I was wondering if anyone could point me to some information about the velocity fluctuations.I know that the error can't be 0 (obviously, though it will be very small). I'm just after something that says I should expect the speed to fluctuate for 0.xx% over a maximum period of a second or something like that. They don't seem to have anything like this in their datasheets.

- A synchronous motor operates with a winding in its rotor it particularly is hooked as much as an exterior resistor for velocity administration throughout initiate-up, jointly as an induction motor, squirrel caged style has no exterior resistor. The rotor windings are short-circuited on the ends and is nearly a squirrel. the cost of a synchronous motor has no slippage. 2,poles-3600 rpm; 4-poles-1800 rpm; 6poles-1200 rpm jointly as an induction motor has a slip velocity, 2poles- 3540 rpm; 4 poles-1750 rpm; 6poles-1150 rpm.A synchronous motor continually operates with carbon brushes, jointly as induction autos would have none.Synchronous autos are often rated a minimum of 100Hp, jointly as, induction autos may well be rated in fractional Hp.

- Q: All I have is a motor, fan, a plug, and about 5 or 6 wires sticking out of one side. How do I get the motor running?

- The link you gave is a dead link. What you have is probably a multi-speed motor that is wired with a speed selector switch. One wire is the common neutral, and the others provide speed control when connected to the power leg in the proper combinations. You will need a wiring diagram and color code for the specific motor. This is not hard to obtain if the motor is made by a company that is still in business. There will be a name plate on the motor somewhere giving the maker's name and the model number. Find the maker's web site and see if the information is available there. If not, hit the contact us tab and get their phone number. Give them a call and they should be able to help you. Good luck.

- Q: What is the principle of the single-phase AC motor in the washing machine?

- The motor of the washing machine should be called: capacitance type single-phase asynchronous motor. The principle is a series capacitor in the amount of the starting winding, the voltage and current of capacitor lags behind its 90 degree, it will produce a magnetic field in the stator, the motor rotating motor! Static centrifugal switch is turned on when the electric starting capacitor in after starting work, when the rotor speed reaches the rated value of 70% to 80% when the centrifugal switch will automatically jump, starting capacitor to complete the task, and disconnected. The running capacitor is connected to the starting winding to participate in the operation. This method is generally used in air compressors, cutting machines, woodworking machines and other heavy load and unstable place.

Send your message to us

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords