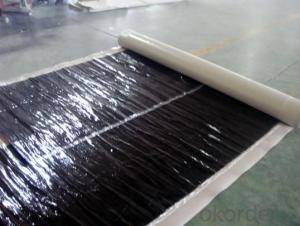

Self Adhesive Modified Bituminous Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

itis a modified bitumen base sheet consisting of polymer modified asphalt added viscosifier inside covering with different upper separated materials and underside with silicone antisticking layer. According to different upper surface, it includes three types: PE film surfacing (SAM-930APE), sand surfacing (SAM-930AS) and antisticking surfacing (SAM-930AN). There have two kinds of thickness: 3.0 mm and 4.0 mm.

Item | Requirement | ||

Soluble matter content, g/m 2 ≥ | 3 mm | 2100 | |

4 mm | 2900 | ||

Tensile property | Tensile strength, N/50mm ≥ | 3 mm | 600 |

4 mm | 800 | ||

Elongation at the maximum tensile force, % ≥ | 40 | ||

Resistance to heat( degree centigrade ) | 70, No sliding, flowing, dripping | ||

Flexibility at low temperature,( degree centigrade ) | -30 | ||

No cracking | |||

Water tightness | Pass at 0.3 MPa, 120 min | ||

Sheering properties N/50mm | Between membranes ≥ | 1.0 | |

Between membrane and aluminum plate ≥ | 1.5 | ||

Shank watertight | Pass | ||

Immersed in oil, pieces ≤ | 2 | ||

Holding Power/ min ≥ | 15 | ||

Thermal ageing | Elongation at the maximum tensile force, % | 40 | |

Flexibility at low temperature,( degree centigrade ) | -28 | ||

No cracking | |||

Sheering properties between membrane and aluminum plate, N/mm | 1.5 | ||

Dimension stability, % ≤ | 1.0 | ||

Self-adhesive bitumen re-peel strength, N/mm ≥ | 1.5 | ||

Usage

Roofs or undergrounds.

Swimming pools, fire pools and reservoirs;

Subways or tunnels;

Open fires-forbidden construction areas;

Cold construction areas.

Advantages

Self adhesive, safe and environment-friendly;

Good tensile strength and elongation;

Strong adaptability for substrate shrinkage, deformation and cracks;

It will be a high-strength membrane to resist water;

Penetration-resisting and corrosion-resisting;

Excellent flexibility in low temperature;

Strong self healing ability for penetration and cracks.

FAQ

1. Is sample available before place orders?

A:Yes, sample is ok。

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Can a waterproofing membrane be painted over?

- Yes, a waterproofing membrane can be painted over. However, it is important to ensure that the membrane is clean, dry, and free from any debris or loose material before applying paint. Additionally, it is recommended to use a paint that is specifically designed for use on waterproofing membranes to ensure proper adhesion and longevity. It is also important to follow the manufacturer's instructions for both the waterproofing membrane and the paint to ensure compatibility and effectiveness.

- Q: Can a waterproofing membrane be used in mining or excavation projects?

- Yes, a waterproofing membrane can be used in mining or excavation projects. Waterproofing membranes are designed to prevent the penetration of water or other liquids, making them suitable for protecting underground structures, tunnels, or mining areas from water ingress. They can help to maintain the stability and integrity of the excavation site, preventing water-related damages and ensuring safety.

- Q: The difference between high polymer modified asphalt waterproofing membrane and sbs

- SBS modified asphalt waterproofing membrane is SBS rubber modified petroleum asphalt cited as the invasion coating, polyester fiber non-woven fabrics, jute cloth, fiberglass mats were made for the fetal base, the plastic film for the anti-sticking isolation Layer, by the selection, ingredients, eutectic, invasion, composite molding, curling and other processes processing production.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic?

- Yes, a waterproofing membrane can be used in areas with heavy foot traffic. In fact, many waterproofing membranes are specifically designed to withstand heavy use and abuse, making them ideal for high-traffic areas such as walkways, balconies, and parking decks. These membranes are typically made from durable materials like rubber, PVC, or modified bitumen, which are resistant to wear and tear. Additionally, some membranes have a slip-resistant surface to improve safety in areas where people are walking. It's important to choose a waterproofing membrane that is suitable for the specific application and meets the required durability standards to ensure long-lasting protection in areas with heavy foot traffic.

- Q: Can a waterproofing membrane be used on tunnels with subway systems?

- Tunnels with subway systems can indeed benefit from the use of a waterproofing membrane. It is strongly advised to incorporate this protective layer into subway tunnel construction to prevent water infiltration and potential harm to the structure and electrical systems. The waterproofing membrane acts as a barrier, effectively excluding water and safeguarding the tunnel against issues caused by moisture, such as corrosion, mold, and deterioration. It is crucial to select a waterproofing membrane that is specially designed for tunnel use and capable of withstanding the unique challenges and conditions of subway systems, including heavy traffic loads, vibrations, and exposure to chemicals. Moreover, it is essential to ensure the installation of the waterproofing membrane is carried out by experienced professionals who adhere to the appropriate guidelines and specifications, guaranteeing its effectiveness and durability.

- Q: Does a waterproofing membrane require any special cleaning or maintenance procedures?

- Yes, a waterproofing membrane typically requires special cleaning and maintenance procedures to ensure its effectiveness and longevity. Regular inspections, cleaning off debris, and addressing any damage or wear are essential to prevent leaks or deterioration. Additionally, specific cleaning products and techniques may be recommended by the manufacturer or installer to maintain the membrane's performance.

- Q: Can a waterproofing membrane be used on PVC roofs?

- PVC roofs, commonly found in commercial and residential buildings, are known for their durability and resistance to weathering. However, like all roofing materials, they can develop leaks and cracks over time. To combat this issue, a waterproofing membrane can be applied to PVC roofs. This membrane, such as EPDM or TPO, is flexible and can easily adhere to the PVC surface, forming a seamless and watertight barrier. It is crucial to ensure that the chosen waterproofing membrane is compatible with PVC roofs and to carefully follow the manufacturer's instructions for proper installation. Additionally, regular maintenance and inspections are highly recommended to promptly detect and address any potential problems before they worsen.

- Q: Can a waterproofing membrane be used on precast gypsum surfaces?

- Yes, a waterproofing membrane can be used on precast gypsum surfaces. Precast gypsum surfaces are often used in construction for walls, ceilings, and other building components. These surfaces are typically porous and can be susceptible to water damage if not properly protected. A waterproofing membrane is a barrier that is applied to the surface of the precast gypsum to prevent water infiltration. It acts as a protective layer, preventing water from seeping into the gypsum and causing damage such as mold growth or deterioration. There are various types of waterproofing membranes available in the market, including liquid-applied membranes, sheet membranes, and cementitious coatings. These membranes are designed to adhere to different types of surfaces, including precast gypsum. When using a waterproofing membrane on precast gypsum surfaces, it is important to ensure that the surface is clean and free from any contaminants that may interfere with the adhesion of the membrane. The membrane should be applied according to the manufacturer's instructions, taking into consideration factors such as temperature, humidity, and drying time. In conclusion, yes, a waterproofing membrane can be used on precast gypsum surfaces to protect them from water damage. It is essential to choose the right type of membrane and follow proper application techniques to ensure effective protection.

- Q: Can waterproofing membranes be used on both horizontal and vertical surfaces?

- Yes, waterproofing membranes can be used on both horizontal and vertical surfaces. Waterproofing membranes are designed to provide a barrier against water penetration and can be applied on various surfaces, including roofs, walls, floors, and even underground structures. They are versatile in their application and can be used to protect both horizontal surfaces such as flat roofs or balconies, as well as vertical surfaces like walls or foundations. The flexibility and durability of waterproofing membranes make them suitable for a wide range of construction projects, ensuring that water does not seep through and cause damage to the structure.

- Q: Can waterproofing membranes be used on shower walls?

- Yes, waterproofing membranes can indeed be used on shower walls. In fact, they are an essential component of shower construction to prevent water leakage and potential damage to surrounding areas. Waterproofing membranes create a barrier that prevents water from seeping through the walls and into the structural components of the shower. They are typically installed behind the tile or other wall covering materials to provide an extra layer of protection. Waterproofing membranes are designed to be flexible, durable, and resistant to moisture, ensuring that the shower walls remain watertight and free from any potential water damage.

Send your message to us

Self Adhesive Modified Bituminous Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords