Self Adhesive Modified Asphalt Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

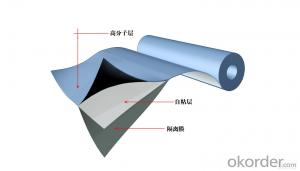

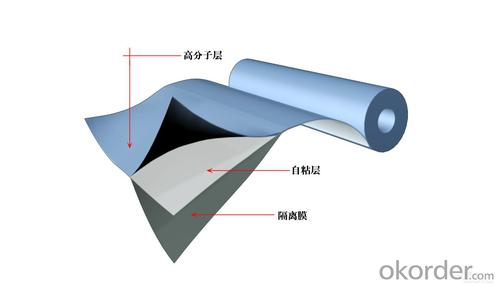

Self-adhesive bitumen waterproof membrane is composed of base material, including synthetic rubber like SBS, good road asphalt andviscosity increaser. The surface is covered by PE film, aluminum foil film, EVA, HDPE, and the silicon depositing release film is covered on the lower surface as anti-sticking layer..

Specification

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications Scope

1) Widely used in the industrial and civil building roofing, underground, pool, tunnel, wooden and metal roofing.

2) Specially applied in the oil depot chemical factory, garment factory, and granary.

3) Especially used in cold places.

4) Tape used for sealing all construction material surfaces.

Advantages

1) Cold-applied construction with no open flame and self-adhesion without bonding agent make it safe, low- carbon, environmental, and economical.

2) Excellent adhesive performance guarantees the integrity of waterproof layer.

3) Good rubber elasticity, elongation and shear stress.

4) Good low-temperature property.

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Can a waterproofing membrane be used on precast glass surfaces?

- Indeed, precast glass surfaces can benefit from the utilization of a waterproofing membrane. It is common for precast glass surfaces to possess joints and seams that allow water to infiltrate. Applying a waterproofing membrane can effectively establish a protective barrier against water penetration. By doing so, the waterproofing membrane acts as a safeguard, preventing moisture from seeping into the joints and causing potential harm to the precast glass. It is crucial to select a waterproofing membrane specifically designed for glass surfaces and to adhere to the manufacturer's guidelines for proper application. Moreover, it is prudent to perform regular maintenance and inspections to ensure that the waterproofing membrane remains effective over time.

- Q: Is a waterproofing membrane breathable?

- Typically, a waterproofing membrane is not breathable. Its main objective is to form a barrier that stops water or moisture from entering. To accomplish this, the membrane is constructed to be impermeable to water molecules. Nonetheless, this impermeability also restricts the passage of air and moisture vapor, leading to a lack of breathability.

- Q: Can a waterproofing membrane be used for a crawl space?

- Yes, a waterproofing membrane can be used for a crawl space. Crawl spaces are susceptible to moisture and water intrusion, which can lead to various issues such as mold growth, structural damage, and unpleasant odors. A waterproofing membrane can act as a barrier to prevent water and moisture from seeping into the crawl space. It is typically installed on the walls and floors of the crawl space, creating a watertight seal. This membrane can effectively prevent water from entering, making it an excellent solution for crawl space waterproofing. Additionally, some waterproofing membranes also have antimicrobial properties, further reducing the risk of mold and mildew growth in the crawl space.

- Q: Can a waterproofing membrane be used on lead surfaces?

- Indeed, lead surfaces commonly exist within the roofing industry, where it is feasible to employ a waterproofing membrane. This application aids in safeguarding against undesirable consequences such as water damage and leaks. It is crucial to ascertain the compatibility of the waterproofing membrane with lead, as certain membranes may induce reactions or deterioration of the lead material. Moreover, adherence to appropriate surface preparation and installation techniques is necessary to achieve a reliable and efficient waterproofing solution. Consulting with a professional or manufacturer to obtain specific product recommendations and installation guidelines is highly advised.

- Q: Can a waterproofing membrane be applied on a sloped surface?

- On a sloped surface, it is possible to apply a waterproofing membrane. In fact, it is even more crucial to apply a waterproofing membrane on a sloped surface compared to a flat one. Sloped surfaces tend to experience more water runoff, which increases the risk of water infiltration and harm to the underlying structure. By applying a waterproofing membrane, a barrier is created to prevent water from penetrating into the structure and instead directs it towards drainage systems. Nonetheless, it is vital to ensure that the membrane is correctly installed and adhered to the slope in order to prevent potential issues such as water pooling or detachment of the membrane. Furthermore, the waterproofing membrane used should be suitable for sloped surfaces and possess the necessary flexibility to accommodate any movements or shifting that may occur.

- Q: Are waterproofing membranes resistant to alkali exposure?

- Yes, waterproofing membranes are typically resistant to alkali exposure. These membranes are designed to provide a protective barrier against water and other harmful substances, including alkalis. They are made from materials such as rubber, bitumen, or polymer-based compounds that have a high resistance to alkali. This ensures that the membrane remains intact and effective even when exposed to alkali-rich environments, such as concrete or cement surfaces. Additionally, these membranes undergo rigorous testing and are specifically manufactured to withstand alkali exposure, making them a reliable solution for waterproofing applications in various industries, including construction and infrastructure.

- Q: Are waterproofing membranes resistant to gasoline vapors?

- Yes, waterproofing membranes are generally resistant to gasoline vapors. They are designed to create a barrier against moisture and other liquids, including gasoline and its vapors.

- Q: Can a waterproofing membrane be used on brick surfaces?

- Yes, a waterproofing membrane can be used on brick surfaces. Waterproofing membranes are designed to provide a barrier against water penetration, and they can be applied to various surfaces including brick. Applying a waterproofing membrane on a brick surface can help prevent water damage, such as moisture seeping into the brick and causing deterioration or mold growth. It is important to choose a waterproofing membrane that is compatible with brick and follow the manufacturer's instructions for proper application. Additionally, it is recommended to consult with a professional to ensure the correct membrane is selected and applied according to the specific needs and conditions of the brick surface.

- Q: Can waterproofing membranes be used on concrete stairs?

- Concrete stairs can indeed benefit from the application of waterproofing membranes. These membranes serve the purpose of establishing a safeguarding barrier, effectively shielding the concrete from water and moisture infiltration, thus averting potential harm. By implementing a waterproofing membrane on concrete stairs, one can effectively extend their longevity, impede deterioration, and minimize the requirement for expensive repairs in the future. It is vital to select a waterproofing membrane specifically crafted for concrete usage and adhere to the manufacturer's guidelines for correct application.

- Q: How does a waterproofing membrane handle exposure to high temperatures?

- The ability of a waterproofing membrane to withstand high temperatures relies on its composition and quality. These membranes are typically made from durable materials like bitumen, EPDM, or PVC, which have high melting points and can resist heat. These materials are carefully selected to ensure that the membrane remains intact and effective even when exposed to elevated temperatures. The resistance of high-quality waterproofing membranes to heat is enhanced through the use of additives and fillers during manufacturing. These additives help the membrane maintain its integrity, preventing it from softening, melting, or becoming brittle under high temperature conditions. Additionally, the successful installation of the waterproofing membrane is crucial to its ability to handle high temperatures. Proper installation techniques, such as ensuring adequate adhesion and seam sealing, are essential for maintaining the membrane's effectiveness and preventing any potential damage caused by heat exposure. To summarize, waterproofing membranes are specifically engineered to withstand high temperatures. Their composition, quality, and installation techniques all contribute to their ability to resist heat without deteriorating or losing their waterproofing properties.

Send your message to us

Self Adhesive Modified Asphalt Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords