Polymer Adhesive Modified Asphalt Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

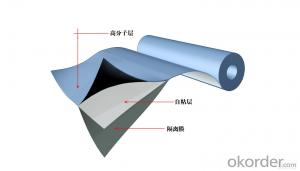

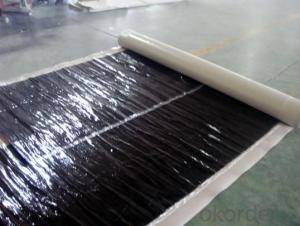

1.Structure of Polymer Adhesive Waterproofing Membrane Description:

Polymer adhesive waterproofing membrane is made of polymer sheet (PVC, PE, EVA, the ECB, TPO, etc.), since the sticky rubber asphalt rubber, the isolation membrane composition, and can according to need in polymer material compound fabric reinforced. Theproduct put the advantages of polymer waterproofing membrane and adhesive waterproofing membrane together,greatly improving the puncture resistance, weather resistance, self-healing, high and low temperature performance, such as a more excellent physical properties, chemical properties more stable.

2.Main Features of Polymer Adhesive Waterproofing Membrane:

•Having the rubber elasticity, excellent elongation

•Excellent sticky relay

•Safe and convenient for construction,no pollution for environment

•Excellent corrosion resistance,aging resistence

3.Polymer Adhesive Waterproofing Membrane Specification;

| Number | Test Item | Index | ||

| 1 | water absorption(%) | <0.01< span=""> | ||

| 2 | in-process shrinkage(%) | 1.55.5- | ||

| 3 | tensile strength(Mpa) | 21-37 | ||

| 4 | breaking extension(%) | >880 |

- Q: Can a waterproofing membrane be used for a dam?

- Yes, a waterproofing membrane can be used for a dam. A waterproofing membrane is a material that is specifically designed to prevent the passage of water. It is commonly used in construction to create a barrier against water intrusion. In the case of a dam, which is a large structure built to hold back water and create a reservoir, it is essential to have an effective waterproofing system to prevent any leakage or seepage of water. A waterproofing membrane can be applied to the surface of the dam to provide an additional layer of protection against water penetration. The membrane is typically made of materials such as rubber, PVC, EPDM, or bitumen, which have excellent water resistance properties. It is installed in multiple layers to ensure a strong and durable barrier against water. The membrane is specifically designed to withstand the high water pressure exerted by the reservoir behind the dam. By using a waterproofing membrane, the dam's integrity can be maintained, ensuring that water does not leak through the structure and cause damage to the surrounding areas. It also helps to prevent erosion and seepage, which can weaken the dam over time. In conclusion, a waterproofing membrane can indeed be used for a dam, providing an effective solution to ensure the dam's watertightness and structural stability.

- Q: Can a waterproofing membrane be used in conjunction with fire protection systems?

- Indeed, the utilization of a waterproofing membrane in tandem with fire protection systems is possible. Although the primary function of a waterproofing membrane is to prevent water infiltration, it can also serve as an additional safeguard against fire hazards. Numerous waterproofing membranes are engineered to possess fire-resistant qualities or exhibit fire-retardant characteristics. Consequently, they aid in impeding the spread of fire and minimizing its impact on the edifice. Furthermore, certain waterproofing membranes are specifically tailored for integration into fire protection systems, such as fire-rated roof membranes or fire-resistant sealants. These specialized membranes effectively seal off potential avenues for fire and establish a barrier to safeguard the underlying structure. In summary, the incorporation of a waterproofing membrane alongside fire protection systems contributes to the overall enhancement of a building's safety and security.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- EPDM roofs can benefit from the use of a waterproofing membrane. This synthetic rubber roofing material, known as EPDM, is popular for low-slope and flat roofs due to its durability and flexibility. Although EPDM roofs are already waterproof, adding a waterproofing membrane can offer an added layer of defense, increasing the roof's lifespan. By acting as a barrier against water infiltration, the waterproofing membrane prevents leaks and moisture-related harm. Nonetheless, it is crucial to guarantee that the chosen waterproofing membrane is compatible with EPDM and installed according to the manufacturer's instructions to preserve the roof's integrity.

- Q: Can a waterproofing membrane be used on fiberglass surfaces?

- Yes, a waterproofing membrane can be used on fiberglass surfaces.

- Q: Can a waterproofing membrane be used on planter boxes?

- Yes, a waterproofing membrane can be used on planter boxes. A waterproofing membrane is typically used to prevent water from seeping through surfaces, and this can be beneficial for planter boxes as it helps to protect the wood or other materials from moisture damage. By applying a waterproofing membrane to the interior of the planter box, it creates a barrier that prevents water from penetrating the material and potentially causing rot or decay. This can extend the lifespan of the planter box and ensure that it remains in good condition for a longer period of time. Additionally, a waterproofing membrane can also help to retain moisture within the planter box, which can be beneficial for the plants or flowers that are being grown. Overall, using a waterproofing membrane on planter boxes can provide added protection and durability.

- Q: Can a waterproofing membrane be used in areas with chemical exposure, such as industrial settings?

- Yes, a waterproofing membrane can be used in areas with chemical exposure, such as industrial settings. However, it is important to ensure that the specific waterproofing membrane chosen is suitable for the chemicals present in the environment. Different waterproofing membranes have different levels of resistance to various chemicals, so it is crucial to select a membrane that can withstand the specific chemical exposure in the industrial setting. Additionally, proper installation and maintenance of the waterproofing membrane are essential to ensure its effectiveness and longevity in such environments. Regular inspections and prompt repairs or replacements should be conducted to address any damage caused by chemical exposure. Overall, with the right selection and maintenance, a waterproofing membrane can provide an effective barrier against water and chemicals in industrial settings.

- Q: Does a waterproofing membrane require any protective coatings or sealants?

- No, a waterproofing membrane typically does not require any additional protective coatings or sealants as it is designed to be a standalone barrier against water penetration.

- Q: Can a waterproofing membrane be used in historic buildings?

- Yes, a waterproofing membrane can be used in historic buildings. Historic buildings often face challenges related to moisture infiltration and water damage due to their age and construction materials. Waterproofing membranes are a common solution to prevent water seepage and protect the building's structural integrity. However, it is important to choose a waterproofing membrane that is compatible with the historic building's materials and construction methods to ensure its preservation and adherence to historical authenticity. Additionally, any waterproofing work done on a historic building should be carried out by professionals with expertise in historic preservation to ensure proper installation and minimal impact on the building's historical value.

- Q: Can a waterproofing membrane be used on different types of surfaces, such as concrete, wood, or metal?

- Yes, a waterproofing membrane can be used on different types of surfaces such as concrete, wood, or metal. Waterproofing membranes are designed to create a barrier that prevents water from penetrating the surface and causing damage. They are versatile and can adhere to various materials, making them suitable for different applications. For concrete surfaces, a waterproofing membrane can be applied to protect against water intrusion and to prevent moisture-related issues such as cracks, corrosion, or mold growth. It can be used on concrete foundations, basements, or retaining walls to ensure they remain dry and structurally sound. When it comes to wood, a waterproofing membrane acts as a protective layer that prevents water absorption, warping, rotting, or decay. It can be applied to exterior surfaces like decks, balconies, or fences to enhance their lifespan and maintain their integrity. In the case of metal surfaces, a waterproofing membrane can be used to prevent rusting and corrosion caused by water exposure. It creates a barrier that seals out moisture, protecting metal roofs, gutters, or other metal structures from water damage. It is important to note that different types of waterproofing membranes may be more suitable for specific surfaces. For example, liquid-applied membranes can be easily applied on irregular surfaces like concrete, while sheet membranes may be more appropriate for flat or smooth surfaces. It is advisable to consult with a professional or manufacturer to determine the most suitable waterproofing membrane for a specific surface and application.

- Q: Are waterproofing membranes resistant to high temperatures?

- The resistance of waterproofing membranes to high temperatures may vary depending on the specific material utilized. Certain waterproofing membranes are specifically engineered to endure high temperatures while retaining their effectiveness and integrity. These membranes often comprise materials like modified bitumen or synthetic rubber, which possess properties that enable them to withstand elevated temperatures. Nevertheless, it should be noted that not all waterproofing membranes possess resistance to high temperatures. Some membranes constructed from PVC or other thermoplastic materials may have limitations when exposed to extreme heat. Therefore, it is imperative to refer to the manufacturer's specifications and guidelines to ensure that the selected waterproofing membrane is appropriate for the intended application and can endure the expected temperature conditions.

Send your message to us

Polymer Adhesive Modified Asphalt Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords