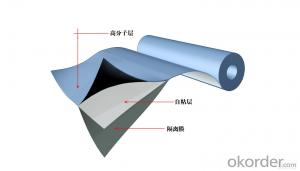

Self adhensive Modified Waterproof Membrance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 15000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Waterproof Membrane | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX |

Model Number: | Excaid-D | thickness:1.2mm,1.5mm,2.0mm: | Raw mateiral:EPDM rubber | width:1200mm: | Standard:GB18173.1--2006 |

length:20m: | Tear strength:>=25KN/m | break tensile strength >=7.5MPa: | waterproof:0.3MPa,30min | break elongation:>=450%: | usage:building waterproof |

Packaging & Delivery

Packaging Details: | PE membrane and pallet |

Delivery Detail: | within 20 days after receiving downpayment |

Specifications

1.ISO9001,ISO14001

2.Top 3 of Chinese waterproof materials manufacturer

3.Customize product property

4.System accessories

Technical Specification:

Type | Waterproof Membrane | |||

Material | EPDM RUBBER | |||

Thickness | 1.2mm; 1.5mm;2.0mm | |||

Weight(kg/m2) | 1.2mm | 1.5mm | 2.0mm | |

1.54-1.58 | 1.79-1.83 | 2.25-2.29 | ||

Length | 20m/Roll | |||

Width | 1.2m | |||

Usage | basements, ponds, Lake, steel structure roofing, underground, tunnels etc. | |||

Packing | 24 sqm/ROLL | |||

Loading in Container | ROLLS | |||

Colors | customized | |||

Enclosure | ||||

- Q: Can a waterproofing membrane be used for historic preservation projects?

- Yes, a waterproofing membrane can be used for historic preservation projects. Waterproofing membranes are commonly used in construction to protect buildings from water damage, and they can be particularly beneficial in preserving historic structures. By preventing water infiltration, the membrane helps to safeguard the integrity of the building, protect against moisture-related deterioration, and extend the lifespan of the historic structure. However, it is important to ensure that the membrane chosen is compatible with the materials and construction techniques used in the historic building to avoid any adverse effects on its authenticity or structural stability.

- Q: Can a waterproofing membrane be used on plywood surfaces?

- Plywood surfaces can benefit from the use of a waterproofing membrane. Plywood is commonly used in construction, including outdoor projects like decks and balconies. However, plywood is not naturally waterproof and can suffer from moisture damage over time. To safeguard plywood surfaces from water damage, a waterproofing membrane can be employed. This membrane functions as a barrier, preventing water from penetrating the plywood and causing rot or decay. There exist various types of waterproofing membranes, such as liquid-applied membranes, sheet membranes, and peel-and-stick membranes. These membranes adhere to the plywood surface and create a tight seal. It is crucial to adhere to the manufacturer's instructions for proper application and ensure the plywood surface is clean and dry before applying the membrane. By utilizing a waterproofing membrane, plywood surfaces can be effectively shielded from water damage, prolonging their lifespan and preserving their structural integrity.

- Q: Does a waterproofing membrane require any specialized tools or equipment for installation?

- Yes, the installation of a waterproofing membrane typically requires specialized tools and equipment. Some of the common tools and equipment used for installation include a trowel or roller for spreading the membrane, a utility knife for cutting and shaping the membrane, a heat gun or propane torch for activating and adhering the membrane, a seam roller for ensuring proper bonding of seams, and a caulking gun for applying sealant around penetrations and edges. Additionally, depending on the specific type of waterproofing membrane being installed, other tools such as a primer, bonding adhesive, or specialized membrane fasteners may be required. It is important to consult the manufacturer's installation guidelines to ensure the proper tools and equipment are used for a successful installation.

- Q: Can a waterproofing membrane be applied to existing structures or is it only suitable for new construction?

- A waterproofing membrane has the capability to be applied to both existing structures and new construction. These membranes are specifically designed to create a barrier against water infiltration, making them suitable for preventing water damage in various areas such as roofs, basements, and foundations. Whether it is an aged building or a recently constructed one, the application of a waterproofing membrane can effectively maintain the dryness of the structure and prevent problems associated with moisture, such as leaks, seepage, and mold growth. However, when applying a waterproofing membrane to an existing structure, it may be necessary to undertake additional preparation and surface treatment in order to ensure proper adhesion and efficiency. It is strongly advised to seek the guidance of an experienced waterproofing contractor who can evaluate the specific requirements of the structure and provide suitable solutions.

- Q: Can a waterproofing membrane be used for bridge decks and roadways?

- Yes, a waterproofing membrane can be used for bridge decks and roadways. Waterproofing membranes are designed to provide a protective layer that prevents water infiltration, which is essential for the long-term durability and performance of bridge decks and roadways. These membranes help to prevent water damage, such as corrosion and cracking, and also protect the underlying structure from moisture-related issues.

- Q: Can a waterproofing membrane be used in earthquake-prone areas?

- Yes, a waterproofing membrane can be used in earthquake-prone areas. Waterproofing membranes are designed to provide a barrier against moisture penetration, and they can also offer some degree of flexibility and elasticity. This allows them to withstand the movement and vibrations caused by earthquakes, helping to protect the structure from water damage and potential leaks. However, it is important to ensure that the chosen membrane meets the specific requirements and standards for earthquake-prone areas to ensure its effectiveness and durability.

- Q: Can a waterproofing membrane be used in shower pans?

- Yes, a waterproofing membrane can be used in shower pans. In fact, it is highly recommended to use a waterproofing membrane in shower pans to prevent water leakage and damage to the underlying structure.

- Q: Can a waterproofing membrane be used for pond or pool applications?

- Yes, a waterproofing membrane can be used for pond or pool applications. Waterproofing membranes are designed to provide a barrier against water penetration, making them an ideal choice for sealing ponds and pools. These membranes are typically made from synthetic materials such as PVC, EPDM, or TPO, which are highly resistant to water and UV rays. They are available in various thicknesses and can be customized to fit the specific dimensions of the pond or pool. Additionally, waterproofing membranes are durable and flexible, allowing them to withstand the constant exposure to water and the movement of the underlying substrate. Overall, using a waterproofing membrane for pond or pool applications can help prevent leaks, prolong the lifespan of the structure, and ensure a safe and enjoyable water environment.

- Q: How does a waterproofing membrane handle settlement cracks?

- Waterproofing membranes are specifically designed to address settlement cracks by offering a continuous and flexible barrier that effectively blocks water infiltration. Settlement cracks arise when the ground beneath a structure shifts or settles, resulting in foundation cracks. These cracks can allow water to seep into the building, causing moisture damage and potential structural problems. In the event of a settlement crack, applying a waterproofing membrane to the affected area creates a seamless and watertight seal. This membrane acts as a protective layer that prevents water from entering through the crack and penetrating the building. Furthermore, it plays a vital role in maintaining the foundation's structural integrity by reducing the likelihood of additional cracking and deterioration. The flexibility of the waterproofing membrane is essential in handling settlement cracks. It can accommodate the movements of the underlying structure without compromising its performance. As the ground settles or shifts, the membrane stretches and contracts, ensuring that the crack remains sealed and the waterproofing system remains intact. Moreover, certain waterproofing membranes possess self-healing properties. This means that if a settlement crack does occur, the membrane has the ability to reseal itself, preserving its watertight integrity. This self-healing capability minimizes the need for frequent repairs and maintenance, leading to time and cost savings for property owners. In conclusion, a waterproofing membrane is a highly effective solution for addressing settlement cracks. It provides a durable and flexible barrier that prevents water infiltration, guards against further damage, and contributes to the longevity of the structure.

- Q: Can a waterproofing membrane be used on tunnels?

- Yes, a waterproofing membrane can be used on tunnels. Tunnels are often subjected to high levels of moisture, groundwater infiltration, and potential leaks. Therefore, it is crucial to protect them from water damage and ensure their long-term structural integrity. Waterproofing membranes are commonly used in tunnel construction to prevent water penetration and provide an effective barrier against moisture. These membranes are designed to be durable, flexible, and resistant to various environmental conditions, making them suitable for use in tunnels. They can be applied to the tunnel walls, roof, and floor to create a waterproof seal, ensuring that the tunnel remains dry and protected from water-related issues such as corrosion, deterioration, and mold growth. Additionally, waterproofing membranes can also help in reducing maintenance costs and extending the lifespan of the tunnel infrastructure.

Send your message to us

Self adhensive Modified Waterproof Membrance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 15000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords