Modified Asphalt Waterproofing Self-adhesive Roofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

Introduction:

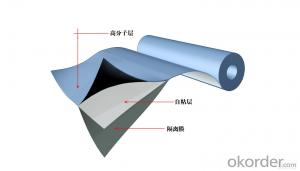

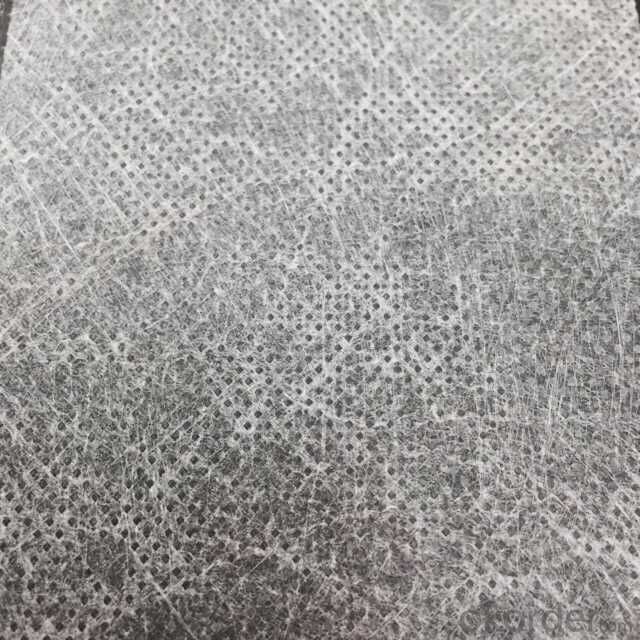

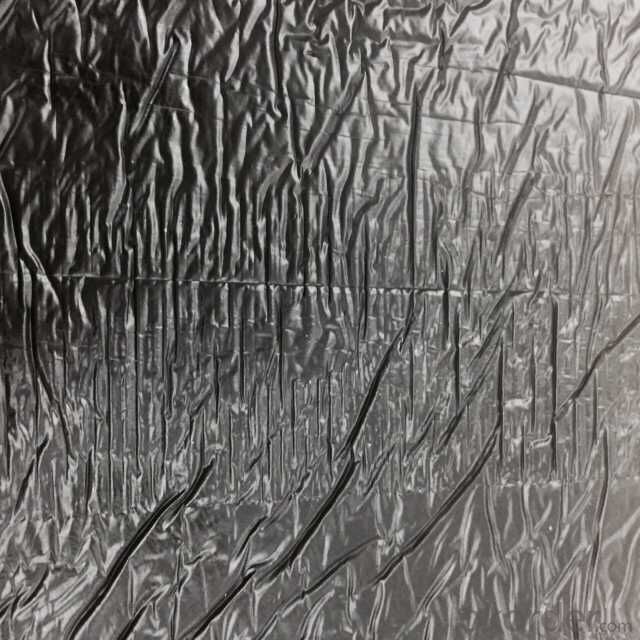

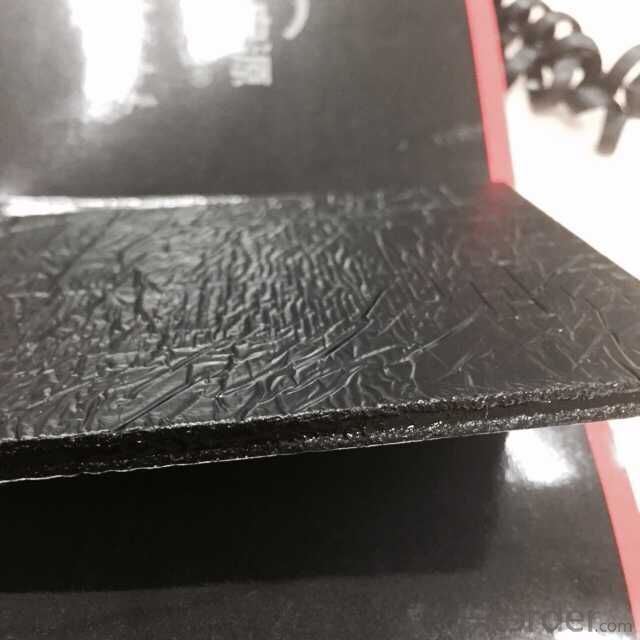

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

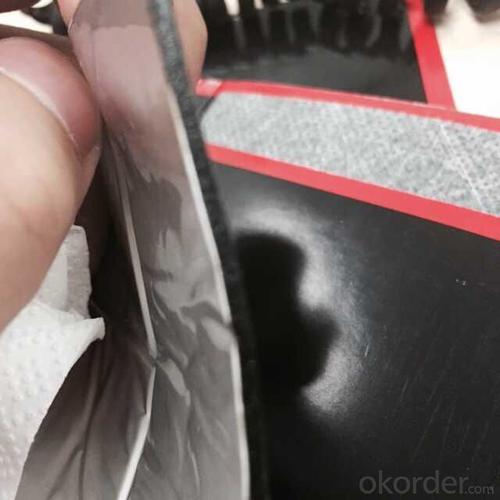

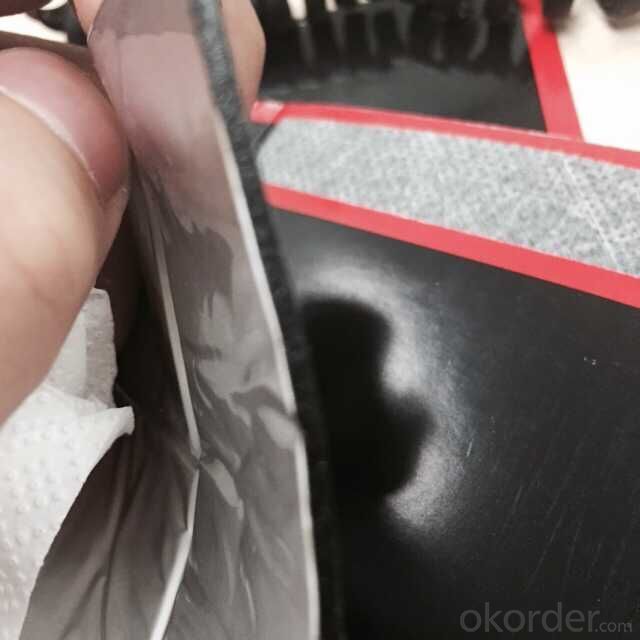

Picture Modified Asphalt Waterproofing Self-adhesive Roofing Membrane:

Storage:

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features:

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage:

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are waterproofing membranes resistant to gas and vapor transmission?

- Yes, waterproofing membranes are generally resistant to gas and vapor transmission. These membranes are designed to create a barrier that prevents the passage of liquid water, as well as gases and vapors, effectively ensuring the protection and integrity of the structure they are applied to.

- Q: Can a waterproofing membrane be used on precast chrome surfaces?

- Yes, a waterproofing membrane can be used on precast chrome surfaces. Waterproofing membranes are often used to protect surfaces from water damage and prevent moisture from seeping into the structure. Precast chrome surfaces can also benefit from the application of a waterproofing membrane to ensure their longevity and durability. The membrane will create a barrier between the surface and any potential water intrusion, thereby protecting the precast chrome and maintaining its appearance and functionality. It is important to choose a waterproofing membrane that is compatible with chrome surfaces and follow the manufacturer's instructions for proper application.

- Q: Can a waterproofing membrane be used for a planter roof?

- Indeed, the utilization of a waterproofing membrane is applicable to a planter roof. The primary purpose of a waterproofing membrane lies in its ability to impede water infiltration, thus rendering it highly suitable for safeguarding the roof of a planter. By doing so, it effectively shields the underlying structure from water-related harm, encompassing potential leakages and decay caused by moisture. Furthermore, the implementation of a waterproofing membrane also aids in preserving moisture within the planter, thereby guaranteeing that plants obtain sufficient hydration.

- Q: Are waterproofing membranes resistant to mineral oils?

- The resistance of waterproofing membranes to mineral oils can differ. Certain membranes are purposely engineered to withstand mineral oils, while others may not possess this capability. To ascertain the resistance level of a specific waterproofing membrane to mineral oils, it is crucial to review the manufacturer's specifications and product details. Moreover, seeking advice from a professional or directly contacting the manufacturer is advised to obtain tailored guidance regarding the compatibility of a waterproofing membrane with mineral oils in your unique scenario.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Yes, waterproofing membranes are typically resistant to chlorine exposure.

- Q: Can a waterproofing membrane be used for swimming pool coping?

- No, a waterproofing membrane cannot be used for swimming pool coping. Coping refers to the material used to cover the top edges of the pool walls and is typically made of concrete, stone, or tile. It is primarily used to provide a finished look and protect the pool structure from water damage. On the other hand, a waterproofing membrane is a material applied to the surface of a structure, such as a basement or roof, to prevent water infiltration. While both serve the purpose of water protection, they are designed for different applications and are not interchangeable.

- Q: Can a waterproofing membrane be used for a hotel swimming pool area?

- Yes, a waterproofing membrane can be used for a hotel swimming pool area. The membrane will provide a barrier against water penetration, helping to keep the pool area dry and prevent any potential damage to the underlying structure.

- Q: Can waterproofing membranes be used on wood surfaces?

- Waterproofing membranes have the capability to be utilized on wood surfaces. These membranes are highly adaptable and can be applied to various materials, including wood. Their main purpose is to establish a safeguarding barrier that hinders water infiltration, thus preventing moisture-related harm such as decay, distortion, or the growth of mold. By correctly applying waterproofing membranes, wood surfaces can be effectively sealed, rendering them impervious to water absorption and enhancing their longevity and robustness. It is crucial to select a waterproofing membrane that is specially developed for wood applications and adhere to the manufacturer's guidelines for appropriate application and upkeep.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- When installing a waterproofing membrane, there are various safety precautions to consider. To begin with, it is crucial to ensure that the installation team uses all necessary personal protective equipment (PPE). This may incorporate gloves, safety glasses, and appropriate footwear to prevent injuries or exposure to dangerous substances. Moreover, it is essential to work in a well-ventilated area to avoid inhaling fumes or vapors emitted during the installation process. If working in a confined space, it is necessary to take proper measures to guarantee sufficient ventilation and use suitable respiratory protection if needed. Furthermore, it is vital to adhere to the manufacturer's instructions and guidelines for the specific waterproofing membrane being installed. This involves understanding any potential hazards linked with the product, such as flammability or toxicity, and taking necessary precautions to prevent accidents or exposure. Another safety consideration is to make sure that the installation area is appropriately prepared before commencing the process. This might entail clearing any debris, cleaning the surface, and addressing any potential hazards or obstacles that could pose a risk to the installation team. Lastly, it is important to have a designated safety plan in place, including emergency procedures and easily accessible first aid kits in case of accidents or injuries. Regular safety inspections and monitoring throughout the installation process are also recommended to promptly identify and address any potential safety risks. By adhering to these safety precautions, the installation of a waterproofing membrane can be carried out securely and effectively, minimizing the risk of accidents or injuries.

- Q: How to distinguish whether the waterproofing membrane is polyester tires?

- Waterproof membrane requirements have good water resistance, stability of the temperature change (high temperature does not flow, no blistering, not confuse; low temperature does not brittle crack), a certain mechanical strength, extensibility and resistance to fracture, to There is a certain degree of flexibility and anti-aging and so on.

Send your message to us

Modified Asphalt Waterproofing Self-adhesive Roofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords