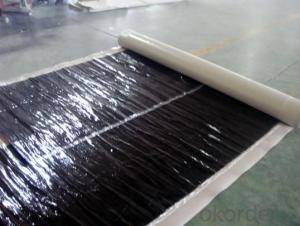

self-adhering polymer modified bituminous waterproof membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 150000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Where to use:

Roofs or undergrounds

Swimming pools, fire pools and reservoirs

Subways or tunnels

Open fires-forbidden construction areas

Cold construction areas

Advantages

Self adhesive, safe and environment-friendly

Goodtensilestrength and elongation

Strong adaptability for substrate shrinkage, deformation and cracks

It will be a high-strength membrane to resist water

Penetration-resisting and corrosion-resisting

Excellent flexibility in low temperature

Strong self healing ability for penetration and cracks

Packaging: JY-100-3 material is packed in rolls with plastic bags or cartons.

Storage: JY-100-3 material should be stored in well-ventilated place and avoid being exposed to the sun or rain. The temperature in stored places can not be higher than 45° C. It should be put vertically not more than in two levels

Transportation: In order to prevent inclination or lateral drift, JY-100-3 material can not be put vertically in double-level

Surface preparation: Surfaces should be dry, clean, smooth and free from any dusts, oil or loose particles. Cracks and uneven places need to be filled by polymer mortar.

- Q: Can waterproofing membranes be used on green roofs?

- Indeed, green roofs can utilize waterproofing membranes. They serve as an indispensable element within green roof systems. The concept of green roofs involves a layer of plants and growing medium situated atop a waterproofing layer. It is this waterproofing layer that safeguards the building structure by preventing water infiltration and subsequent damage. The waterproofing membranes employed in green roof applications are specifically engineered to withstand the unique challenges posed by such installations, including exposure to water, UV radiation, and root penetration. These membranes are typically composed of durable materials such as PVC, TPO, or EPDM, renowned for their exceptional waterproofing capabilities. Moreover, certain waterproofing membranes used on green roofs may possess additional attributes like root resistance and UV stability, thereby ensuring the roof's longevity and imperviousness. Ultimately, the utilization of waterproofing membranes on green roofs plays a vital role in establishing a sustainable and enduring roofing system that not only provides water protection but also offers environmental advantages.

- Q: Can a waterproofing membrane be used on precast plastic surfaces?

- Yes, a waterproofing membrane can be used on precast plastic surfaces. Waterproofing membranes are designed to create a barrier against moisture and can be applied to a variety of surfaces, including concrete, metal, and plastic. When properly installed, a waterproofing membrane can provide protection against water infiltration, ensuring the longevity and durability of the precast plastic surface. It is important to choose a waterproofing membrane that is compatible with plastic and follow the manufacturer's instructions for application to ensure proper adhesion and effectiveness.

- Q: Are waterproofing membranes resistant to corrosion?

- Yes, waterproofing membranes are typically resistant to corrosion. They are specifically designed to withstand exposure to moisture, chemicals, and other potentially corrosive substances, ensuring long-lasting protection against water infiltration and damage.

- Q: Can a waterproofing membrane be used on modified bitumen roofs?

- Yes, a waterproofing membrane can be used on modified bitumen roofs. In fact, it is a common practice to enhance the waterproofing capabilities of modified bitumen roofs by applying a separate waterproofing membrane on top. This additional layer provides an extra barrier against water infiltration and helps prolong the lifespan of the roof.

- Q: Can a waterproofing membrane be used for planter boxes?

- Indeed, planter boxes can benefit from the utilization of a waterproofing membrane. The main purpose of a waterproofing membrane is to obstruct the passage of water through various surfaces, making it an effective remedy for safeguarding the planter box and its surroundings against water damage. When a waterproofing membrane is installed internally within the planter box, it establishes a protective barrier that prevents water from infiltrating the underlying materials, such as wood or concrete, thus prolonging the lifespan of the planter box. Furthermore, the presence of a waterproofing membrane can also assist in retaining moisture within the planter box, which proves advantageous for the plants thriving inside. Nonetheless, it is crucial to exercise caution when selecting a waterproofing membrane, ensuring that it is specifically tailored for planter boxes and poses no harm to the plants, thereby guaranteeing optimal outcomes.

- Q: Can waterproofing membranes be used on buried pipelines?

- Yes, waterproofing membranes can be used on buried pipelines. These membranes create a barrier that prevents water from infiltrating the pipeline, protecting it from corrosion and other forms of damage.

- Q: Are waterproofing membranes resistant to saltwater?

- Waterproofing membranes, in general, possess resistance to saltwater. Their purpose is to establish a barricade that hinders water infiltration into surfaces such as roofs, walls, or foundations. These membranes are created using materials like rubber, polyethylene, or PVC, which have an inherent ability to withstand the corrosive impact of saltwater. This resistance enables waterproofing membranes to adequately safeguard structures and surfaces against water-induced harm, even in saltwater surroundings. Nonetheless, it is crucial to select a waterproofing membrane specifically tailored for saltwater applications in order to guarantee optimal effectiveness and durability.

- Q: Can a waterproofing membrane be used in agricultural structures?

- Yes, a waterproofing membrane can be used in agricultural structures. Agricultural structures such as barns, greenhouses, and storage facilities often require protection from moisture and water damage. A waterproofing membrane is a durable and flexible material that can be applied to different surfaces such as roofs, walls, and floors to prevent water infiltration. It acts as a barrier, preventing water from seeping into the structure and causing damage to the building materials, equipment, and stored crops. Additionally, a waterproofing membrane can also help regulate the temperature and humidity levels within the agricultural structure, creating a more controlled and optimal environment for crops, livestock, and equipment. Overall, using a waterproofing membrane in agricultural structures can help ensure the longevity and functionality of the building while protecting the valuable assets inside.

- Q: Can a waterproofing membrane be used on tunnels with water drainage systems?

- Tunnels with water drainage systems can indeed utilize a waterproofing membrane. The purpose of this membrane is to create a protective barrier against water infiltration and effectively prevent any leakage into the tunnel. However, it is crucial to ensure that the waterproofing membrane is compatible with the specific water drainage system in place. The installation of the membrane must be done in a manner that does not hinder or disrupt the functioning of the drainage system. Moreover, it is important to carefully consider the design and installation of the drainage system to ensure efficient water management and avoid any potential complications that may compromise the effectiveness of the waterproofing membrane. By carefully planning and executing the installation, a waterproofing membrane can effectively uphold the overall integrity and durability of tunnels with water drainage systems.

- Q: Can a waterproofing membrane be used for residential swimming pools?

- Yes, a waterproofing membrane can be used for residential swimming pools. These membranes are specifically designed to provide a water-resistant barrier, preventing leakage and protecting the structure of the pool. Waterproofing membranes are commonly used in various applications, including swimming pools, to ensure durability and longevity of the pool.

Send your message to us

self-adhering polymer modified bituminous waterproof membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 150000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords