Monolithic Refractories for Iron and Steel Industry:Refractory Castable for Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Castable for Fireplaces and Industrial Furnaces

Product Description:

Gunning castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by clients. Gunning castables use high purity raw materials and additives as the main material, and are made with superfine powder adding technology.

Product Features:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, and also excellent working ability. If should be used with the same material products.

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

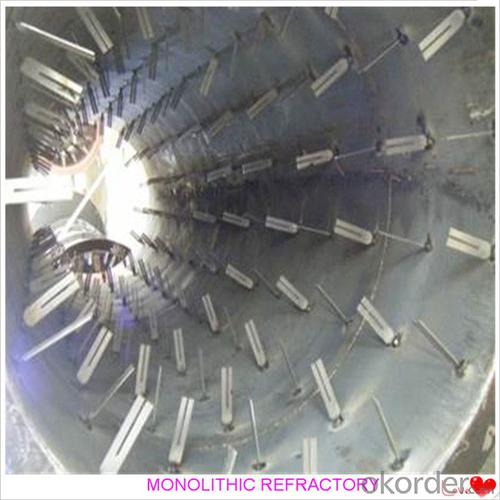

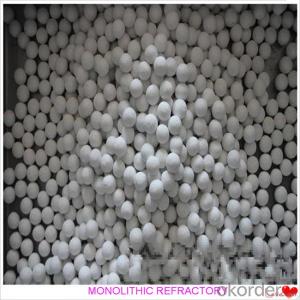

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are Abrasion Resistant Coatings?

A3: ARC's abrasion resistant coatings guard against the severe wear and erosion that can chip away your plant's bottom line. These high-performance coatings protect new equipment as well as rebuild worn equipment at a fraction of traditional replacement costs.

- Q: How does the composition of monolithic refractories impact their performance?

- The composition of monolithic refractories greatly impacts their performance. The choice of raw materials, such as aggregates, binders, and additives, determines the refractory's properties, such as strength, thermal conductivity, chemical resistance, and thermal expansion. The correct composition ensures that the refractory can withstand high temperatures, resist corrosion, and maintain its structural integrity even under severe conditions. A well-designed composition also improves the refractory's workability and ease of installation, allowing for efficient and effective lining applications.

- Q: In iron and steel industry, the main raw materials for blast furnace ironmaking are iron ore, coke and limestone. What's the use of limestone here?

- Calcium oxide absorbs sulfur dioxide and prevents it from polluting the air.

- Q: What is the role of monolithic refractories in blast furnaces?

- Monolithic refractories play a crucial role in blast furnaces as they provide high-temperature resistance and excellent durability in the harsh operating conditions of the furnace. Blast furnaces are used in the ironmaking process to convert iron ore into molten iron, and monolithic refractories are essential for lining the interior of the furnace. One of the main functions of monolithic refractories in blast furnaces is to withstand extreme temperatures. The interior of a blast furnace can reach temperatures of up to 2,500 degrees Celsius, and monolithic refractories are designed to maintain their structural integrity and protect the furnace lining from thermal shock and erosion caused by the high temperatures. Monolithic refractories also provide insulation, preventing heat loss from the furnace. This is important as it helps to maintain the desired temperature for efficient iron production. By reducing heat loss, monolithic refractories contribute to energy savings and improved overall furnace performance. Another crucial role of monolithic refractories is to resist chemical attack from the molten iron and slag. The materials used in blast furnaces, such as iron ore, coke, and limestone, undergo various chemical reactions during the ironmaking process. Monolithic refractories are engineered to resist the corrosive effects of these reactions, ensuring a longer service life for the furnace lining. Furthermore, monolithic refractories offer excellent mechanical strength and resistance to abrasion. The materials being processed in a blast furnace, including iron ore and coke, can be abrasive. Monolithic refractories provide a protective barrier against the abrasive action, preventing damage to the furnace lining and extending its lifespan. In summary, the role of monolithic refractories in blast furnaces is to withstand extreme temperatures, provide insulation, resist chemical attack, and offer mechanical strength against abrasion. These properties contribute to the efficient operation and longevity of blast furnaces, enabling the production of molten iron for various industrial applications.

- Q: What are the challenges in recycling and disposing of monolithic refractories?

- One challenge in recycling and disposing of monolithic refractories is the high temperature resistance and durability of these materials, which makes them difficult to break down and recycle. Additionally, the presence of various contaminants, such as metals and other impurities, can further complicate the recycling process. Proper disposal of monolithic refractories also poses challenges due to the potential environmental impact of disposing of these materials, as they may contain hazardous substances. Therefore, finding efficient and environmentally-friendly methods for recycling and disposing of monolithic refractories remains a challenge in the industry.

- Q: How do monolithic refractories resist high temperatures?

- Monolithic refractories resist high temperatures due to their unique composition and structure. These refractories are made from a single material or a blend of materials, such as alumina, silica, and magnesia, which have high melting points and can withstand extreme heat. Additionally, their monolithic nature eliminates joints and seams, reducing the risk of thermal shock and allowing them to adapt to thermal expansion and contraction. Their dense and compact structure also minimizes porosity, preventing the penetration of heat and ensuring their durability under high-temperature conditions.

- Q: How do monolithic refractories withstand high temperatures and thermal shocks?

- Monolithic refractories are able to withstand high temperatures and thermal shocks due to their unique composition and structure. They are made from a single, continuous material, which eliminates the presence of joints or seams that could weaken the refractory's integrity. This monolithic nature allows for better thermal conductivity and reduced heat transfer, enabling the material to withstand extreme temperatures without cracking or breaking. Additionally, monolithic refractories possess high thermal shock resistance, meaning they can withstand rapid temperature changes without experiencing significant damage. This resilience is achieved through the use of additives and bonding agents that enhance the material's ability to expand and contract uniformly, minimizing the risk of thermal shock-induced fractures. Overall, the cohesive design and specialized components of monolithic refractories enable them to endure high temperatures and thermal shocks more effectively than other refractory materials.

- Q: How do monolithic refractories perform in high-temperature environments?

- Due to their unique characteristics, monolithic refractories are highly effective in high-temperature environments. Unlike traditional refractories made of multiple bricks or tiles, these refractories are composed of a single, continuous composition. This monolithic structure offers several advantages when it comes to performance in high-temperature conditions. First and foremost, monolithic refractories exhibit excellent thermal shock resistance. They can endure rapid temperature changes without cracking or spalling. While high temperatures can impose significant stress on materials, the monolithic structure allows for better expansion and contraction, minimizing the risk of damage. Furthermore, monolithic refractories possess high resistance to chemical attack. In high-temperature environments, aggressive chemical agents are often present, which can corrode and erode traditional refractory materials. However, the monolithic composition is typically designed to be chemically inert, creating a protective barrier against these corrosive elements. Moreover, monolithic refractories offer superior strength and durability at high temperatures. Their single composition ensures a dense and compact structure, reducing the likelihood of cracking or breaking under extreme thermal conditions. This strength enables them to maintain their integrity and performance even in the most demanding environments. Additionally, monolithic refractories can be easily installed and repaired. Unlike traditional refractories that demand precise brick or tile placement, monolithic materials can be poured or sprayed into place, adapting to any shape or size. This flexibility expedites installation, making it more cost-effective and reducing downtime and maintenance costs. Overall, monolithic refractories excel in high-temperature environments due to their thermal shock resistance, chemical inertness, durability, and ease of installation. Their capacity to withstand extreme heat and harsh conditions makes them the preferred choice for industries such as steel, cement, glass, and petrochemicals, where high temperatures are prevalent.

- Q: What are the recommended curing times for monolithic refractories?

- The recommended curing times for monolithic refractories vary depending on the specific type and manufacturer's instructions. However, in general, it is recommended to allow monolithic refractories to cure for at least 24 to 48 hours before subjecting them to any heat or thermal stress. It is important to follow the specific curing guidelines provided by the manufacturer to ensure optimal performance and longevity of the refractory material.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish drying systems?

- Monolithic refractories improve the efficiency of ladle and tundish drying systems by providing superior thermal insulation, reduced heat loss, and increased resistance to thermal shock. These refractories have high thermal conductivity and low heat capacity, enabling faster and more uniform heating of the ladle and tundish. Additionally, their monolithic nature eliminates joints and seams that could lead to heat leakage, ensuring better heat retention and improved energy efficiency. The enhanced thermal properties of monolithic refractories contribute to quicker drying times and reduced energy consumption in ladle and tundish drying processes, ultimately improving overall system efficiency.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish drying furnaces?

- The efficiency of ladle and tundish drying furnaces is enhanced by monolithic refractories in multiple ways. To begin with, monolithic refractories provide a high level of thermal insulation. These refractories possess low thermal conductivity, effectively minimizing heat transfer from the furnace to the surrounding environment. This insulation property helps to reduce heat losses and maintain a higher temperature within the furnace for a longer duration. Consequently, the drying process becomes more efficient as the heat is retained within the furnace, resulting in a decrease in overall energy consumption. Furthermore, monolithic refractories exhibit exceptional resistance to thermal shock. The rapid temperature fluctuations that occur during the heating and cooling cycles of the furnace can cause stress and cracks in the refractory material. However, monolithic refractories are designed to withstand these thermal shocks and maintain their structural integrity. This durability ensures a longer lifespan for the refractory lining, reducing the need for frequent repairs or replacements. Consequently, the furnace operates at optimal efficiency without the downtime associated with maintenance. In addition, monolithic refractories offer excellent mechanical strength and abrasion resistance. These properties are crucial in ladle and tundish drying furnaces, which are subjected to mechanical stresses and abrasive substances like molten metal and slag. The use of monolithic refractories ensures that the lining can endure these harsh conditions without suffering structural damage. This resistance to wear and tear increases the overall efficiency of the furnace, enabling it to operate uninterrupted for longer periods. Lastly, monolithic refractories provide greater design flexibility compared to traditional brick or tile refractories. They can be easily cast or gunned onto the lining surface, simplifying installation and repair processes. This flexibility allows the furnace to be customized and adapted to meet specific requirements, ensuring optimal heat distribution and efficient drying processes. In conclusion, monolithic refractories enhance the efficiency of ladle and tundish drying furnaces through their thermal insulation, resistance to thermal shock, mechanical strength, and design flexibility. By reducing heat losses, increasing durability, withstanding harsh conditions, and facilitating easy installation and repair, these refractories optimize the performance and energy efficiency of the furnaces.

Send your message to us

Monolithic Refractories for Iron and Steel Industry:Refractory Castable for Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords