Monolithic Refractories for Iron and Steel Industry - Calcined Petroleum Coke with Stable Quality

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Factory Background

The factory is majorly running and operating carbon additive (pitch coke, calcined petroleum coke and anthracite), low nitrogen carbon additive, and brake pad making material. Company is the long term supplier of Sinosteel Corporation, Shanghai Carbon Corporation, the plant of SGL Group the Carbon Company in China and some largest special carbon products producing plants.

YUAI also supplies huge amout of high quality carbon additive and graphite carbon additive to steel plants, foundries and ferrotungsten plants. YUAI has been assigned by BAO STEEL as the only organization for processing pitch coke for export purpose. The group’s major products are constantly exported to Japan, Korea, Malaysia, South East Asia countries, Europe and America, which receive praises by our consumers.

The group has invested numbers of calcinators in Anhui China to ensure the capability of producing and processing huge amount of carbon additive. Further investment is on process. According to the orders from customers, YUAI is able to processing and providing different specifications of carbon additive and other products. To provide best quality of products and to offer customers most satisfied service is YUAI’s operating objectives.

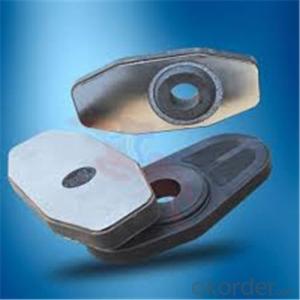

Calcined Petroleum Coke

FC:98.5%min,

S:0.5%max

A:0.8%max

V:0.7%max

Mositure:0.5%max

Size:1-5mm

This product is mainly used in steel-making and foundry. Calcined Petroleum Coke

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Packaging & Delivery

Packaging Detail:25kg paper bag into 1t weaving bag 5kg, 10kg and 20kg weaving bag into 1t weaving bag 25kg weaving bag put on pallet covered with entanglement wrap product direct into packing bag 25kg paper bag put on pallet covered with entanglement Wrap 25kg weaving bag into 1t weaving bag.

Delivery Details: 7 days

- Q: What are the advantages of using low-cement castables in the iron and steel industry?

- There are numerous benefits associated with the utilization of low-cement castables in the iron and steel sector. To begin with, low-cement castables necessitate less water compared to traditional castables. Consequently, the installation process becomes faster and more efficient due to the reduced water requirement. Moreover, the lower water content results in enhanced strength development and shorter drying time, facilitating faster turnaround times during production. In addition, low-cement castables exhibit exceptional resistance to extreme temperatures and thermal shocks. Given the high temperatures prevalent in the iron and steel industry, these castables possess excellent refractory properties that enable them to withstand such harsh conditions. Consequently, the refractory lining enjoys an extended service life, reducing the need for frequent repairs or replacements. Furthermore, low-cement castables demonstrate remarkable mechanical strength and abrasion resistance. Given the nature of the iron and steel sector, where heavy materials and abrasive substances are handled, the refractory lining is susceptible to wear and tear. However, low-cement castables are capable of enduring these mechanical stresses, thereby enhancing the durability and longevity of the lining. Moreover, low-cement castables possess low porosity and high density, resulting in reduced permeability. Consequently, they exhibit high resistance to alkali attacks, chemical corrosion, and slag penetration, all of which are common challenges faced in the iron and steel industry. By employing low-cement castables, the risk of refractory failure caused by these corrosive elements is minimized. Lastly, low-cement castables contribute to improved energy efficiency. Their lower thermal conductivity ensures that less heat is conducted through the refractory lining, leading to reduced heat losses. This, in turn, translates into energy savings, as less heat is wasted and more heat is retained within the system. The significance of this advantage is particularly evident in the iron and steel industry, where energy costs can be substantial. In conclusion, the use of low-cement castables in the iron and steel sector offers a multitude of advantages, including reduced water requirement, superior thermal resistance, enhanced mechanical strength, improved resistance to chemical corrosion, and increased energy efficiency. These benefits contribute to overall cost savings, heightened productivity, and improved operational performance in the iron and steel manufacturing process.

- Q: How do monolithic refractories contribute to the reduction of heat loss in iron and steel plants?

- Monolithic refractories play a crucial role in reducing heat loss in iron and steel plants through their high thermal insulation properties. These refractories are designed to withstand extreme temperatures and provide excellent resistance to thermal shock and erosion. By lining the walls, roofs, and floors of various equipment and structures in the plants, monolithic refractories help to create a barrier that prevents heat from escaping into the surrounding environment. This insulation not only conserves energy but also ensures efficient heat transfer within the plant, leading to improved productivity and cost-effectiveness.

- Q: How do monolithic refractories improve the quality and consistency of iron and steel products?

- Monolithic refractories enhance the quality and consistency of iron and steel products by providing excellent resistance to high temperatures, thermal shock, and chemical attacks. These refractories form a seamless lining within the furnaces and other equipment used in the production process, ensuring optimal insulation and minimizing heat loss. This insulation helps in maintaining stable and controlled temperatures, preventing unwanted variations that can affect the final product's quality. Additionally, monolithic refractories' durability and resistance to wear and tear contribute to consistent and reliable performance, resulting in improved iron and steel product quality.

- Q: How do monolithic refractories withstand mechanical stress in the iron and steel industry?

- Monolithic refractories in the iron and steel industry withstand mechanical stress primarily due to their composition and installation techniques. These refractories are made from a single, solid material, which provides them with excellent strength and resistance to mechanical pressure. Additionally, they are typically installed using specialized techniques, such as gunning or ramming, which ensure proper bonding and densification. These factors collectively enable monolithic refractories to effectively withstand the intense mechanical stress encountered in the iron and steel industry.

- Q: How do monolithic refractories contribute to the quality of iron and steel products?

- Monolithic refractories play a crucial role in the production of high-quality iron and steel products. They provide superior resistance to extreme temperatures, chemical reactions, and mechanical stress in the production process. By maintaining the integrity of furnaces, ladles, and other equipment, monolithic refractories ensure consistent heat distribution and prevent contamination, resulting in improved product quality. Additionally, their ability to withstand thermal shock and erosion prolongs the lifespan of the refractory linings, reducing downtime and enhancing overall efficiency.

- Q: What are monolithic refractories and how are they different from other refractory materials?

- Monolithic refractories are a type of refractory material that is produced and applied in a single, unified form. Unlike other refractory materials, such as bricks or tiles, monolithic refractories are not pre-formed into specific shapes or sizes. Instead, they are generally composed of a mix of aggregates, binders, and additives, which are then installed in place and cured to form a solid, dense structure. One key difference between monolithic refractories and other refractory materials is their versatility and ease of installation. Traditional refractory bricks or tiles require skilled labor and careful assembly to create a lining or structure. Monolithic refractories, on the other hand, can be poured, sprayed, or gunned into place, allowing for a much faster and more efficient installation process. This makes them particularly suitable for complex shapes or areas that are difficult to access. Another difference lies in the physical properties of monolithic refractories. While bricks and tiles are typically characterized by their high mechanical strength and resistance to thermal shock, monolithic refractories can be tailored to exhibit a wide range of properties. They can be engineered to have excellent thermal insulation, superior corrosion resistance, or enhanced abrasion resistance, depending on the specific application requirements. This flexibility makes monolithic refractories suitable for a variety of industries, including steel, cement, glass, and petrochemical. Furthermore, monolithic refractories have the advantage of being able to expand and contract with temperature changes, unlike rigid brick structures. This thermal flexibility helps to minimize cracking and damage caused by thermal cycling, prolonging the lifespan of the refractory lining. Additionally, monolithic refractories offer better refractory integrity and reduced joint failure, as there are no seams or weak points that can be susceptible to thermal stresses. In summary, monolithic refractories are a versatile and convenient type of refractory material that can be customized to meet specific application requirements. Their ease of installation, thermal flexibility, and tailor-made properties make them distinct from other refractory materials such as bricks or tiles.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish preheaters?

- Monolithic refractories improve the efficiency of ladle and tundish preheaters by providing excellent insulation, high thermal conductivity, and resistance to thermal shock. These properties allow for better heat retention, reduced heat loss, and quicker and more uniform heating of the ladle and tundish, ultimately improving the overall efficiency of the preheating process.

- Q: How do monolithic refractories enhance the performance of ladle and tundish purging systems?

- Monolithic refractories play a crucial role in enhancing the performance of ladle and tundish purging systems in several ways. Firstly, monolithic refractories offer excellent thermal insulation properties. Ladle and tundish purging systems require high temperatures to effectively remove impurities and gases from molten metal. The use of monolithic refractories helps to minimize heat loss and maintain the desired temperature within the system. This ensures that the purging process is carried out efficiently and effectively. Secondly, monolithic refractories provide superior erosion and corrosion resistance. During the purging process, the molten metal and purging gases can be highly corrosive and abrasive. Monolithic refractories are designed to withstand such harsh conditions, preventing erosion and corrosion of the lining. This prolongs the lifespan of the ladle and tundish purging systems, reducing the need for frequent repairs or replacements. Furthermore, monolithic refractories offer excellent strength and stability. Ladle and tundish purging systems experience significant mechanical stresses due to the movement of molten metal and purging gases. The use of monolithic refractories ensures the structural integrity of the lining, preventing any deformation or failure under these conditions. This allows for smooth and uninterrupted purging operations, improving the overall performance of the system. In addition, monolithic refractories provide ease of installation and maintenance. Unlike traditional brick and mortar refractories, monolithic refractories can be easily applied as a single, homogeneous layer. This simplifies the installation process and reduces the time and effort required for maintenance. Any necessary repairs or replacements can be carried out more efficiently, minimizing downtime and maximizing the productivity of the ladle and tundish purging systems. Overall, monolithic refractories enhance the performance of ladle and tundish purging systems by providing excellent thermal insulation, erosion and corrosion resistance, strength and stability, as well as ease of installation and maintenance. These properties contribute to the efficient and effective removal of impurities and gases from molten metal, ensuring high-quality output and optimizing the overall productivity of the purging process.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish drying systems?

- Monolithic refractories improve the efficiency of ladle and tundish drying systems by providing superior thermal insulation, reduced heat loss, and increased resistance to thermal shock. These refractories have high thermal conductivity and low heat capacity, enabling faster and more uniform heating of the ladle and tundish. Additionally, their monolithic nature eliminates joints and seams that could lead to heat leakage, ensuring better heat retention and improved energy efficiency. The enhanced thermal properties of monolithic refractories contribute to quicker drying times and reduced energy consumption in ladle and tundish drying processes, ultimately improving overall system efficiency.

- Q: What are the key properties of pumpable refractories used for monolithic refractory applications?

- The key properties of pumpable refractories used for monolithic refractory applications include high flowability, good workability, excellent bonding strength, and high resistance to thermal shock. These pumpable refractories should also possess good pumpability and be able to withstand the intense heat and mechanical stress in the application environment. Additionally, they should have low water demand, high chemical resistance, and the ability to maintain their properties even after exposure to high temperatures.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Calcined Petroleum Coke with Stable Quality

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords