Monolithic Refractories for Iron and Steel Industry - Calcined Petroleum Coke Supply with Large Quantity

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Factory Background

The factory is majorly running and operating carbon additive (pitch coke, calcined petroleum coke and anthracite), low nitrogen carbon additive, and brake pad making material. Company is the long term supplier of Sinosteel Corporation, Shanghai Carbon Corporation, the plant of SGL Group the Carbon Company in China and some largest special carbon products producing plants.

YUAI also supplies huge amout of high quality carbon additive and graphite carbon additive to steel plants, foundries and ferrotungsten plants. YUAI has been assigned by BAO STEEL as the only organization for processing pitch coke for export purpose. The group’s major products are constantly exported to Japan, Korea, Malaysia, South East Asia countries, Europe and America, which receive praises by our consumers.

The group has invested numbers of calcinators in Anhui China to ensure the capability of producing and processing huge amount of carbon additive. Further investment is on process. According to the orders from customers, YUAI is able to processing and providing different specifications of carbon additive and other products. To provide best quality of products and to offer customers most satisfied service is YUAI’s operating objectives.

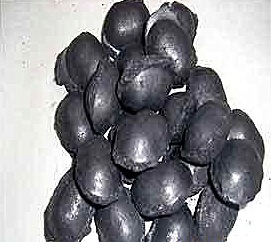

Calcined Petroleum Coke

FC:98.5%min,

S:0.5%max

A:0.8%max

V:0.7%max

Mositure:0.5%max

Size:1-5mm

This product is mainly used in steel-making and foundry. Calcined Petroleum Coke

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Packaging & Delivery

Packaging Detail:25kg paper bag into 1t weaving bag 5kg, 10kg and 20kg weaving bag into 1t weaving bag 25kg weaving bag put on pallet covered with entanglement wrap product direct into packing bag 25kg paper bag put on pallet covered with entanglement Wrap 25kg weaving bag into 1t weaving bag.

Delivery Details: 7 days

- Q: How are monolithic refractories different from traditional brick refractories?

- There are several differences between monolithic refractories and traditional brick refractories. Firstly, monolithic refractories are composed of a single, homogeneous material, whereas traditional brick refractories are made up of individual bricks that are pieced together. This variance in construction allows monolithic refractories to possess a more uniform and consistent structure, which can enhance their performance and durability. Secondly, installing monolithic refractories is typically easier compared to traditional brick refractories. Due to their composition, they can be poured or sprayed into place, eliminating the need for precise bricklaying and mortar application. This simplified installation process saves time and labor during construction or repair projects. Furthermore, monolithic refractories often exhibit superior resistance to thermal shock when compared to traditional brick refractories. The homogeneous structure of monolithic refractories enables them to expand and contract more uniformly under thermal stress, reducing the risk of cracking and failure. This characteristic makes monolithic refractories more suitable for applications with rapid temperature changes, such as in furnaces or kilns. Additionally, monolithic refractories offer better resistance to chemical attacks and erosion. Traditional brick refractories may have joints and gaps between bricks, which can become vulnerable to chemical reactions or erosion over time. Conversely, monolithic refractories possess a seamless structure that minimizes the risk of chemical penetration and erosion, enhancing their longevity and performance. In conclusion, monolithic refractories provide advantages in terms of uniformity, ease of installation, thermal shock resistance, and chemical resistance compared to traditional brick refractories. These disparities make monolithic refractories the preferred choice for numerous industrial applications that involve high temperatures and harsh environments.

- Q: What are the main factors affecting the thermal expansion of monolithic refractories?

- The main factors affecting the thermal expansion of monolithic refractories include the chemical composition of the refractory material, the temperature at which it is exposed, and the rate at which it is heated or cooled. Other factors such as the presence of impurities, the porosity of the material, and the type of bonding agents used can also influence the thermal expansion behavior of monolithic refractories.

- Q: How are monolithic refractories used in the repair and maintenance of ladle and tundish linings?

- Monolithic refractories, widely utilized in the steel industry, are a specific type of refractory material employed for the repair and maintenance of ladle and tundish linings. These linings, integral to the transportation and treatment of molten metal during the steelmaking process, can deteriorate over time when exposed to high temperatures and corrosive conditions. This deterioration poses various issues, including heat loss, contamination of the molten metal, and reduced lifespan of the refractory lining. To tackle these problems, monolithic refractories serve as effective repair and maintenance materials. Typically composed of different refractory aggregates, binders, and additives, monolithic refractories are available in various forms like castables, gunning mixes, and ramming mixes. These materials are designed for easy application and shaping, conforming to the specific geometry and dimensions of the ladle or tundish lining. During the repair process, damaged sections of the lining are removed, and monolithic refractories are then applied. Castables can be poured and vibrated into place, while gunning mixes can be sprayed using a high-pressure gunning machine. On the other hand, ramming mixes are manually compacted into the lining using a ramming tool. Monolithic refractories offer several advantages when it comes to the repair and maintenance of ladle and tundish linings. Firstly, their flexibility ensures easy installation and shaping, resulting in a snug fit to the lining. This maximizes the effectiveness of the refractory lining in preventing heat loss and maintaining the integrity of the ladle or tundish. Secondly, monolithic refractories exhibit exceptional resistance to thermal shock and chemical attack. This durability enables them to withstand the harsh conditions encountered in ladles and tundishes. Even when subjected to repeated heating and cooling cycles, they remain intact without cracking or spalling, providing long-lasting protection to the lining. Lastly, monolithic refractories can be easily repaired and replaced as needed. The application and removal processes are relatively straightforward, facilitating efficient maintenance of ladle and tundish linings. This minimizes downtime and ensures the overall productivity of the steelmaking process. In conclusion, monolithic refractories play a vital role in the repair and maintenance of ladle and tundish linings. Their easy application, exceptional resistance to thermal shock and chemical attack, and ease of repair make them ideal materials for extending the lifespan and optimizing the performance of these linings in the steel industry.

- Q: How do monolithic refractories contribute to the safety of iron and steel operations?

- Monolithic refractories play a crucial role in enhancing the safety of iron and steel operations. These refractories are made of a single, continuous material, which offers several benefits that contribute to the overall safety of the operations. Firstly, monolithic refractories provide excellent thermal insulation. They are designed to withstand high temperatures, preventing heat transfer to the surrounding environment. This insulation property helps in maintaining a safe working temperature for the operators, reducing the risk of burns or other heat-related injuries. Furthermore, monolithic refractories have high resistance to chemical attack. In iron and steel operations, various chemicals and molten metals are used, which can be corrosive and hazardous. The use of monolithic refractories as lining materials creates a protective barrier that resists the corrosive effects of these substances, preventing leaks and potential accidents. Another safety benefit is the ability of monolithic refractories to withstand mechanical stress. Steelmaking processes involve heavy machinery and equipment, which can exert significant pressure on the refractory linings. Monolithic refractories have excellent mechanical strength, which enables them to withstand these stresses and maintain their integrity. This prevents the risk of sudden failure or collapse, reducing the possibility of accidents and injuries due to falling debris. Additionally, monolithic refractories offer easy installation and repair. They can be applied as a castable or gunning material, allowing for quick and efficient lining of furnaces, ladles, and other equipment. This ease of installation reduces downtime during maintenance or repairs, minimizing the risk of accidents caused by delayed or prolonged shutdowns. In summary, monolithic refractories contribute to the safety of iron and steel operations through their excellent thermal insulation, resistance to chemical attack, ability to withstand mechanical stress, and ease of installation and repair. By providing a protective barrier, these refractories help in preventing injuries, maintaining a safe working environment, and minimizing the potential hazards associated with high temperatures, corrosive substances, and mechanical failures.

- Q: How do monolithic refractories mitigate heat loss in iron and steel operations?

- Monolithic refractories possess unique properties and composition that make them highly effective in reducing heat loss in iron and steel operations. Unlike other refractories, monolithic ones are made from a single, continuous material, making them resistant to cracks and gaps that could potentially allow heat to escape. One major advantage of monolithic refractories lies in their exceptional thermal conductivity and insulation properties. With their low thermal conductivity, they are able to effectively limit the transfer of heat from hot areas to cooler surroundings. This insulation characteristic helps maintain high temperatures within iron and steel operations, resulting in reduced heat loss to the environment. Another contributing factor to heat loss mitigation is the ability of monolithic refractories to form a tight seal with the metal structures they are applied to. They adhere well to surfaces and fill in any gaps or irregularities, creating a solid barrier against heat loss. By minimizing the possibility of heat escaping, these refractories ensure that the energy generated within the operations is utilized effectively. Additionally, monolithic refractories exhibit high resistance to thermal shock. In the iron and steel industry, rapid temperature fluctuations are common, which can lead to material deterioration and cracks. However, monolithic refractories possess the ability to withstand these temperature changes without compromising their structural integrity. This guarantees the longevity and effectiveness of the refractories in mitigating heat loss. In summary, monolithic refractories play a vital role in reducing heat loss in iron and steel operations through their excellent insulation, ability to form a tight seal, and resistance to thermal shock. These properties enable them to maintain high temperatures, optimize energy utilization, and enhance overall process efficiency.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish preheaters?

- The efficiency of ladle and tundish preheaters can be significantly improved through the utilization of monolithic refractories, which play a vital role in this process. To begin with, monolithic refractories possess exceptional thermal insulation properties. Their low thermal conductivity ensures that heat loss from the preheaters is effectively prevented. By minimizing heat loss, monolithic refractories ensure that the majority of the heat generated by the preheater is utilized for preheating the ladle or tundish. This results in reduced energy consumption and enhanced efficiency of the preheating process. Additionally, monolithic refractories offer remarkable resistance to thermal shocks. As ladle and tundish preheaters are subjected to rapid and extreme temperature changes during operation, it is crucial for the refractories to withstand these shocks. The ability of monolithic refractories to endure these thermal shocks ensures their long-lasting performance, reducing the need for frequent repairs or replacements. This not only enhances the efficiency of the preheaters but also reduces downtime and maintenance costs. Furthermore, monolithic refractories exhibit excellent mechanical strength and resistance to abrasion. The constant wear and tear experienced by ladle and tundish preheaters due to the movement of ladles or tundishes, as well as the abrasive nature of the materials being processed, can be mitigated through the use of monolithic refractories. These refractories prevent erosion and damage to the preheaters, ensuring their longevity and optimal functioning. Consequently, this improves the overall efficiency of ladle and tundish preheaters by reducing downtime and maintenance requirements. Lastly, monolithic refractories offer the advantage of design flexibility. They can be customized and shaped to meet the specific requirements of ladle or tundish preheaters. This allows for better fitting and insulation, maximizing heat transfer efficiency. The ability to tailor the refractory lining to the preheater's design also ensures uniform heating, minimizing temperature variations and improving overall operational efficiency. In conclusion, monolithic refractories contribute to the improved efficiency of ladle and tundish preheaters by providing superior thermal insulation, resistance to thermal shocks, mechanical strength, abrasion resistance, and design flexibility. These properties result in reduced heat loss, minimized downtime, enhanced durability, and optimized heat transfer, ultimately leading to improved efficiency of the preheating process.

- Q: Can monolithic refractories be used for the lining of reheating furnaces and walking beam furnaces?

- Monolithic refractories, which are refractory materials that can be cast or gunned into place rather than being made up of individual bricks or precast shapes, can be utilized for the lining of both reheating furnaces and walking beam furnaces. This characteristic makes them highly adaptable and versatile for a variety of furnace applications. Reheating furnaces are employed to heat metal products to a specific temperature before undergoing further processing, such as rolling or forging. The lining of these furnaces is exposed to high temperatures, thermal cycling, and mechanical stress. Given their exceptional thermal shock resistance and ability to withstand rapid temperature changes without cracking or spalling, monolithic refractories are well-suited for these conditions. In the steel industry, walking beam furnaces are utilized for the continuous heating and transportation of steel slabs or billets. These furnaces necessitate a lining material that can endure the abrasion and mechanical stress caused by the movement of the material. Monolithic refractories with high abrasion resistance and good mechanical strength are ideal for lining walking beam furnaces. Moreover, monolithic refractories provide additional advantages such as straightforward installation, decreased downtime for repairs, and enhanced energy efficiency. They can be customized to fit specific furnace designs and can be easily repaired or replaced as needed. In conclusion, monolithic refractories are a suitable option for lining reheating furnaces and walking beam furnaces due to their ability to withstand high temperatures, thermal cycling, mechanical stress, and abrasion. Their versatility, ease of installation, and repair make them the preferred choice for these furnace applications.

- Q: What are the advantages of using low-moisture castables in the iron and steel industry?

- Low-moisture castables offer several advantages in the iron and steel industry. Firstly, they have a lower water content, which allows for faster and easier installation. This results in reduced downtime and increased productivity. Secondly, low-moisture castables have excellent strength and thermal shock resistance, making them highly durable in high-temperature applications. This helps to prolong the lifespan of refractory linings, saving on maintenance and replacement costs. Additionally, their low moisture content minimizes the risk of steam explosions during installation or curing. Lastly, these castables offer improved energy efficiency by reducing heat loss, resulting in lower fuel consumption and greenhouse gas emissions. Overall, the use of low-moisture castables in the iron and steel industry enhances operational efficiency, durability, and environmental sustainability.

- Q: What are the main factors affecting the erosion resistance of monolithic refractories?

- The erosion resistance of monolithic refractories is influenced by several key factors. These factors include the chemical composition of the refractory material, the microstructure of the material, the temperature and environment in which it is used, and the mechanical properties of the material. The chemical composition of the monolithic refractory plays a crucial role in its erosion resistance. Certain chemical elements and compounds can enhance the resistance of the refractory to erosion, while others may make it more susceptible. For example, the addition of alumina (Al2O3) in the refractory composition can improve its resistance to erosion, as it forms a protective layer on the surface. On the other hand, the presence of impurities or excess amounts of certain elements can weaken the refractory and increase its susceptibility to erosion. The microstructure of the monolithic refractory is another important factor affecting erosion resistance. The refractory's microstructure refers to the arrangement and distribution of its constituent particles. A well-structured microstructure with a uniform distribution of particles can provide better erosion resistance as it ensures a more even distribution of load during exposure to erosive forces. Conversely, a poorly structured microstructure with clusters or weak bonding between particles may lead to localized erosion and failure. The temperature and environment in which the refractory is used also significantly influence erosion resistance. High temperatures can cause thermal stresses, chemical reactions, and phase changes in the refractory material, all of which can affect its erosion resistance. Additionally, the presence of corrosive gases, liquids, or slags can accelerate erosion by promoting chemical reactions or attacking the refractory material, leading to its degradation. Lastly, the mechanical properties of the monolithic refractory, such as its strength, hardness, and toughness, contribute to erosion resistance. A refractory with higher mechanical strength and hardness can withstand erosive forces better than a weaker material. Similarly, a higher toughness helps the refractory resist cracking or spalling when subjected to impact or thermal shock, reducing its vulnerability to erosion. In summary, the erosion resistance of monolithic refractories is influenced by the chemical composition, microstructure, temperature and environment, and mechanical properties of the material. Understanding and optimizing these factors can help in developing refractories with improved erosion resistance for various industrial applications.

- Q: What are the key factors to consider when designing the lining system with monolithic refractories?

- To ensure optimal performance and longevity of the lining, several key factors must be taken into account when designing a system with monolithic refractories. These factors include: 1. Material selection: It is crucial to choose the appropriate monolithic refractory material, considering factors such as operating temperature, chemical environment, and mechanical stress. Different materials have varying properties and performance characteristics, so selecting the most suitable one for the specific application is essential. 2. Thermal expansion: Like any other material, monolithic refractories expand and contract with temperature changes. Therefore, it is important to consider the thermal expansion properties and how they will interact with the surrounding structure. To prevent cracking or spalling, proper expansion joints or design features should be incorporated. 3. Installation technique: The method of installation plays a critical role in the lining system's performance. Following the manufacturer's guidelines for mixing, placing, and curing the refractory material is essential. Improper installation can compromise lining integrity, thermal conductivity, and structural stability. 4. Bonding and anchoring: To ensure effective lining performance, a strong bond between the monolithic refractory and the substrate is necessary. Proper surface preparation, suitable bonding agents, and appropriate anchoring techniques should be considered to enhance adhesion and stability. 5. Structural design: The structural design of the lining system should be carefully planned to withstand mechanical stresses and operational conditions. Load-bearing capacity, thermal shock resistance, and thermal cycling must be taken into consideration during the design phase. Reinforcement materials, such as steel fibers or mesh, may be required to enhance structural integrity and prevent cracking or spalling. 6. Maintenance and repair: Anticipating the need for maintenance and repair is crucial for the lining system's longevity. Access points, inspection ports, and repair techniques should be considered. Regular inspections and proactive maintenance can help identify and address issues before they escalate and cause major failures. By considering these key factors, a well-designed and effective lining system with monolithic refractories can be ensured, capable of withstanding harsh conditions and providing long-term performance.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Calcined Petroleum Coke Supply with Large Quantity

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords