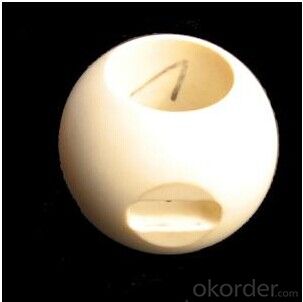

Monolithic Refractories Ceramic Lined Ceramic Ball Valve for Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

Applied in any media, expect HF (Hydrofluoric Acid) or glass solution, with max. temperature up to 500°C or max pressure 5.0 Mpa, such as high corrosion, high attrition and middle pressure.

Structural: 3-part flange type float ball valve Flange standards follow DIN/ANSI/API/JIS

l Excellent wear-proof property of ceramic enables this valve have high reliability and prolonged lifespan which is 2-4times as much as Titannium Alloy and Monel Metal valve.

l Elastic O ring fit between metal part and ceramic part makes the whole part high sealing capacity, unables the two parts blind, and avoid the ball broken.

l Valve steams are selected among 316/316L stainless steel, HC alloy, Monel Alloy, structural ceramic.

l Completely symmetric design ensures dual leak-proof and two-direction usage to prolong its lifespan to twice.

All parts that connect the medium are made of structural ceramics with extremely high chemical stability and hardness (HRC 90), which is only inferior to diamond. So the valve features exceedingly high wear-proof capability, corrosion resisting, enduring capability, good heat insulation, small thermal expansion.

The valve is unique in granule medium of high hardness, or erosive soft granule and is the only choice for such medium. They are wisely used in FDG System, Slag system and LNCFS in power plant, saline water and distilling processes in alkali works, paper pulp system in paper mill, and so on.

The ball is processed by advanced polishing equipment and technology that can ensure high circularity, good surface quality,.

The self-lubricating capability of ZrO2, ensure the good sealing performance between the ball and its seat. It is thoroughly free from the defects of easy leakage, big torque, non-resistance sealing surface comparing with metal sealing valve.

ZrO2 Composition Chart of MZ Ceramic Ball Valve

NO. | Physical Property | Parameter |

1 | Crystal | >85% cubic, the rest monoclinic |

2 | Lg. Loss | 0.8%-1.0% |

3 | Average | 0.4-0.7um |

4 | Apparent Density | >0.4g/cc |

5 | ZrO2 Purity | >99.95% |

6 | Tapped Density | >0.8g/cc |

- Q: How are monolithic refractories inspected and tested for quality assurance?

- To ensure the reliability and performance of monolithic refractories, a series of rigorous processes are conducted for quality assurance. These inspections and tests play a crucial role in maintaining consistent quality standards and identifying any potential defects or weaknesses in the refractory material. The first step involves conducting visual inspections to check for visible defects such as cracks, spalling, or signs of poor manufacturing. This helps in identifying any obvious issues that may affect the refractory's performance. Following that, specialized equipment is used to measure physical properties such as density, porosity, and thermal conductivity. These measurements are then compared against predetermined standards to ensure that the refractory material meets the required specifications. Density and porosity are important indicators of the refractory's strength and resistance to heat and chemicals, while thermal conductivity determines its ability to efficiently transfer heat. Moreover, mechanical tests are performed to assess the refractory's strength and resistance to mechanical stress. This involves subjecting the material to compressive, tensile, and flexural forces to evaluate its structural integrity and durability. To ensure the refractory's suitability for high-temperature environments, thermal tests are conducted. These tests involve exposing the refractory to extreme temperatures and monitoring its behavior. Parameters such as thermal expansion and shrinkage, resistance to thermal shock, and thermal cycling are evaluated during these tests. Chemical analysis is another important aspect of quality assurance for monolithic refractories. Samples of the refractory material are analyzed to determine their chemical composition and assess their resistance to various corrosive environments. This analysis helps ensure that the refractory is suitable for the specific applications it will be used in. Finally, field tests may be conducted at actual operating sites to evaluate the refractory's performance under real-world conditions. These tests involve monitoring the refractory's behavior in terms of wear and tear, thermal insulation, and resistance to chemical attack. The results obtained from field tests are crucial in validating the refractory's performance and making any necessary adjustments to the manufacturing process. In conclusion, monolithic refractories undergo a comprehensive inspection and testing process that includes visual inspections, physical and mechanical tests, thermal analysis, chemical analysis, and field tests. This systematic approach guarantees that the refractories meet the required quality standards, providing reliability and durability in the demanding environments they are designed for.

- Q: How do monolithic refractories resist abrasion in the iron and steel industry?

- Monolithic refractories are specifically designed to resist abrasion in the iron and steel industry due to their unique composition and properties. These refractories are made from a single homogeneous material, which allows them to exhibit exceptional strength and durability when subjected to continuous abrasion. One of the key factors that contribute to the abrasion resistance of monolithic refractories is their high density. These refractories are manufactured with tightly packed particles, ensuring a solid and compact structure. This density helps to minimize wear and tear caused by the constant movement of materials, such as iron and steel, within the industry. Additionally, monolithic refractories often contain high levels of alumina, which is known for its excellent abrasion resistance. Alumina is a highly refractory material that can withstand high temperatures and mechanical stress without deteriorating. Its presence in monolithic refractories provides a protective layer that resists abrasion caused by the movement and impact of iron and steel particles. Moreover, monolithic refractories can be designed with specific additives and binders that further enhance their resistance to abrasion. These additives can include silicon carbide, mullite, or zirconia, which are known for their superior mechanical strength and ability to withstand wear. The binders used in the manufacturing process also contribute to the refractory's integrity and ability to withstand abrasion by providing a cohesive structure. Overall, the combination of high density, alumina content, specialized additives, and binders makes monolithic refractories highly resistant to abrasion in the iron and steel industry. These refractories are capable of withstanding the harsh conditions and constant movement of materials, ensuring longevity and efficiency in various applications within the industry.

- Q: What are the different techniques for installing monolithic refractories?

- Installing monolithic refractories can be accomplished using various techniques, each with its own advantages and suitability for different applications. Some commonly employed methods are as follows: 1. Casting: This involves creating a slurry by mixing the refractory material with water or a binder. The resulting mixture is then poured into molds or directly onto the prepared surface. Once set and hardened, it forms a solid monolithic structure. 2. Gunning: By utilizing a gunning machine, the refractory material is sprayed onto the surface. The material is combined with water or a binder to form a wet mix, which is then propelled onto the surface at high velocity. Gunning is commonly used for on-site repairs or lining larger areas. 3. Ramming: In this technique, the refractory material is compacted into place using a pneumatic or manual ramming tool. Prior to ramming, the material is typically preheated to decrease moisture content and enhance workability. Ramming is often employed for lining smaller areas or filling gaps between bricks or precast shapes. 4. Shotcreting: Similar to gunning, shotcreting involves using a dry mix of refractory material. The dry mix is combined with water or a binder just before being sprayed onto the surface using a high-pressure nozzle. Shotcreting is frequently used for lining larger areas or creating intricate shapes. 5. Troweling: This technique entails applying the refractory material onto the surface using a trowel or similar tool. The material used is typically a wet mix that is spread and smoothed manually. Troweling is commonly employed for patching or repairing small areas, as well as for adding finishing touches. 6. Vibrating: By using a vibrating tool or vibrator, the refractory material is compacted and any air pockets are eliminated. Vibrating is often used to improve the density and strength of the monolithic refractory after it has been installed using other techniques. It is essential to consider various factors, such as the type of refractory material, the size and shape of the area to be lined, and the specific requirements of the application when selecting the appropriate technique. Additionally, proper surface preparation and adherence to installation guidelines are crucial to ensure the effectiveness and longevity of the monolithic refractory.

- Q: What are the advantages of using plastic refractories in the iron and steel industry?

- There are several advantages of using plastic refractories in the iron and steel industry. Firstly, plastic refractories offer excellent thermal insulation properties. They have low thermal conductivity, which means they can effectively retain heat and prevent excessive heat loss during the manufacturing process. This is crucial in the iron and steel industry as maintaining high temperatures is essential for the proper functioning of furnaces and other equipment. Secondly, plastic refractories have superior resistance to chemical attack and corrosion. They can withstand exposure to various chemicals, including molten metals and slag, without deteriorating or losing their structural integrity. This is especially important in the iron and steel industry, where materials come into contact with highly corrosive substances on a regular basis. Another advantage of plastic refractories is their ease of installation and repair. Unlike other refractory materials, plastic refractories can be easily shaped and molded into the desired form, allowing for precise fitting and quick installation. Additionally, they can be easily repaired or patched in case of damage or wear, which reduces downtime and maintenance costs. Furthermore, plastic refractories exhibit good mechanical strength and abrasion resistance. This enables them to withstand the physical stresses and mechanical forces present in the iron and steel industry, such as vibrations, impacts, and mechanical loading. Their high resistance to wear and tear ensures longevity and reduces the need for frequent replacements. Lastly, plastic refractories have a high thermal shock resistance. They can withstand rapid temperature changes without cracking or spalling. This is beneficial in the iron and steel industry, where materials are subjected to extreme temperature differentials, such as during the heating and cooling cycles of furnaces. In conclusion, the advantages of using plastic refractories in the iron and steel industry include excellent thermal insulation, resistance to chemical attack, ease of installation and repair, good mechanical strength, abrasion resistance, and high thermal shock resistance. These properties make plastic refractories an ideal choice for various applications in this industry, ensuring efficient and reliable operations.

- Q: What are the key properties of shotcrete mixes used for monolithic refractory applications?

- The key properties of shotcrete mixes used for monolithic refractory applications include high strength, low porosity, high abrasion resistance, good thermal shock resistance, and excellent adhesion to the substrate. These properties ensure the durability and effectiveness of the shotcrete in withstanding high temperatures and harsh conditions in refractory applications.

- Q: How do monolithic refractories enhance the performance of ladle and tundish preheating systems?

- Monolithic refractories play a crucial role in enhancing the performance of ladle and tundish preheating systems in several ways. Firstly, monolithic refractories offer excellent thermal insulation properties, which help in retaining heat within the ladle and tundish preheating systems. This insulation capability minimizes heat loss, ensuring that the preheating systems operate at optimal temperatures. By maintaining a consistent and high heat level, monolithic refractories enable efficient preheating of ladles and tundishes, reducing the time required for the preheating process. Secondly, monolithic refractories have high refractoriness, meaning they can withstand extreme temperatures without undergoing any significant degradation. This feature is essential in ladle and tundish preheating systems, as they are subjected to intense heat during operation. The ability of monolithic refractories to withstand high temperatures ensures their longevity and prevents premature failure, leading to improved performance and reliability of the preheating systems. Furthermore, monolithic refractories have excellent resistance to thermal shock. Ladles and tundishes are often subjected to rapid temperature changes during the preheating process, which can cause thermal stress and result in cracking and spalling of the refractory lining. However, monolithic refractories, with their superior thermal shock resistance, can withstand these rapid temperature fluctuations without sustaining any significant damage. This resistance to thermal shock ensures the integrity of the refractory lining, prolonging the lifespan of the ladle and tundish preheating systems and enhancing their overall performance. Additionally, monolithic refractories offer good mechanical strength and abrasion resistance. Ladles and tundishes are frequently subjected to mechanical forces, such as stirring and pouring of molten metal. The presence of monolithic refractories with high mechanical strength and abrasion resistance ensures that the refractory lining remains intact even under such harsh conditions. This durability allows for prolonged and efficient operation of the preheating systems, contributing to their enhanced performance. In summary, monolithic refractories enhance the performance of ladle and tundish preheating systems by providing excellent thermal insulation, high refractoriness, resistance to thermal shock, and good mechanical strength and abrasion resistance. These properties enable efficient and reliable preheating, minimize heat loss, prevent premature failure, and prolong the lifespan of the preheating systems, ultimately improving their overall performance.

- Q: How do monolithic refractories contribute to the overall reliability of iron and steel processes?

- Monolithic refractories play a crucial role in enhancing the overall reliability of iron and steel processes in several ways. Firstly, they provide excellent thermal insulation, which helps in maintaining consistent and controlled temperatures within the furnaces and other equipment involved in the production process. This ensures the stability of the process and avoids any sudden temperature fluctuations that could lead to equipment failure or product quality issues. Secondly, monolithic refractories offer high resistance to thermal shocks and mechanical stresses, which are common in iron and steelmaking operations. These refractories can withstand extreme temperatures, rapid heating and cooling cycles, and the corrosive nature of molten metals, thereby prolonging the lifespan of the equipment and reducing the frequency of repairs or replacements. Moreover, monolithic refractories have a superior ability to resist chemical attacks from molten metals, slag, and other harsh substances encountered in iron and steel processes. This resistance prevents the refractories from deteriorating or corroding over time, ensuring their integrity and preventing any contamination of the metal being produced. Lastly, the use of monolithic refractories allows for greater design flexibility and ease of installation compared to traditional brick refractories. This flexibility enables the construction of complex shapes and structures, optimizing the efficiency and productivity of iron and steelmaking processes. Overall, monolithic refractories contribute significantly to the reliability of iron and steel processes by providing excellent thermal insulation, resistance to thermal shocks and chemical attacks, and facilitating flexible design and installation options.

- Q: What are the challenges in repairing and maintaining monolithic refractories?

- There are several challenges associated with repairing and maintaining monolithic refractories. One major challenge is the complex nature of the materials used in monolithic refractories. These materials are often a combination of several components, including aggregates, binders, and additives. The selection and proportioning of these components can greatly impact the performance and durability of the refractory, making it difficult to determine the exact repair or maintenance method. Another challenge is the high temperatures at which monolithic refractories operate. These materials are designed to withstand extreme heat, which can range from several hundred to several thousand degrees Celsius. Repairing or maintaining monolithic refractories at such high temperatures requires specialized equipment and techniques to ensure the safety of the workers and the integrity of the repair. Additionally, monolithic refractories are often exposed to harsh environments, such as corrosive gases, chemical reactions, and mechanical stresses. These factors can lead to degradation and damage over time, requiring regular inspections and maintenance. Identifying and addressing these issues in a timely manner can be challenging, as the damage may not always be visible or easily accessible. Furthermore, monolithic refractories are commonly used in complex industrial processes, such as steelmaking, cement manufacturing, and petrochemical production. These processes often involve continuous operation, which limits the time available for repairs and maintenance. Finding suitable windows of opportunity for maintenance and coordinating the shutdowns of these processes can be a logistical challenge. Lastly, the cost of repairing and maintaining monolithic refractories can be significant. The materials used in monolithic refractories can be expensive, and the labor and equipment required for repairs and maintenance can add up. Balancing the cost of repairs with the need to maintain productivity and extend the service life of the refractories can be a challenge for plant operators and maintenance teams. In conclusion, the challenges in repairing and maintaining monolithic refractories stem from the complex nature of the materials, the high temperatures involved, the harsh operating environments, the complexity of industrial processes, and the cost considerations. Overcoming these challenges requires expertise, careful planning, and effective coordination to ensure the longevity and performance of monolithic refractories.

- Q: How do monolithic refractories contribute to the safety of iron and steel plants?

- Monolithic refractories play a crucial role in enhancing the safety of iron and steel plants. These refractories are designed to withstand extreme temperatures, thermal shocks, and chemical reactions, making them highly resistant to the harsh conditions within the plants. By providing a strong and durable lining for furnaces, ladles, and other equipment, monolithic refractories prevent leaks, cracks, and failures that could lead to accidents, such as molten metal spills or explosions. Their ability to effectively contain heat and protect against wear and tear ensures the structural integrity of the plants, minimizing the risk of equipment failure and potential hazards.

- Q: What are the advantages of using self-flow castables in the iron and steel industry?

- There are several advantages of using self-flow castables in the iron and steel industry. Firstly, self-flow castables offer excellent flowability, which means they can easily fill complex shapes and intricate molds. This allows for greater design flexibility and the ability to create more intricate and precise components. Additionally, the high flowability ensures that there are no gaps or voids in the casting, resulting in a higher quality product with improved mechanical properties. Secondly, self-flow castables have a high degree of homogeneity. This means that the composition of the castable is evenly distributed, resulting in consistent properties throughout the casting. This is particularly important for the iron and steel industry, where uniformity is crucial for achieving desired performance characteristics. Moreover, self-flow castables have a low water demand, which leads to reduced drying and curing times. This is beneficial in terms of production efficiency, as it allows for faster casting cycles and shorter overall production times. Additionally, the reduced water demand also leads to lower drying shrinkage, minimizing the risk of cracking or distortion during the curing process. Another advantage of using self-flow castables is their excellent thermal shock resistance. This is particularly important in the iron and steel industry, where materials are subjected to extreme temperatures. Self-flow castables have the ability to withstand rapid and drastic temperature changes without cracking, which ensures the longevity and durability of the cast components. Furthermore, self-flow castables have good abrasion resistance, which is essential in applications where the castings are exposed to abrasive materials or environments. The high resistance to wear and tear ensures a longer service life and reduces the need for frequent repairs or replacements. In conclusion, the advantages of using self-flow castables in the iron and steel industry include excellent flowability, high homogeneity, low water demand, good thermal shock resistance, and strong abrasion resistance. These benefits contribute to improved casting quality, increased production efficiency, enhanced durability, and reduced maintenance costs.

Send your message to us

Monolithic Refractories Ceramic Lined Ceramic Ball Valve for Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords