Monolithic Refractories for Iron and Steel Industry - Castable for Fireplace and Industrial Furnace Cement Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Castable For Fireplace and Industrial Furnace Cement Industry

Product Description:

Gunning castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by the clients. The gunning castables are used high purity raw materials and additives as the main material, and made of under superfine powder adding technology.

Product Advantages:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, also has a fine working ability.They should be used with the same material products.

Product Applications:

For feature of gunning castable, they have excellent abrasion resistance, thermal shock resistance, high-temperature resistance, anti-corrode and have high intensity.

Designed for refractory lining of blast furnace iron and slag runners, skimmers and soon

They can be used in troughs of small and mid size BFs and in all positions of the troughs where fast tapping is required.

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

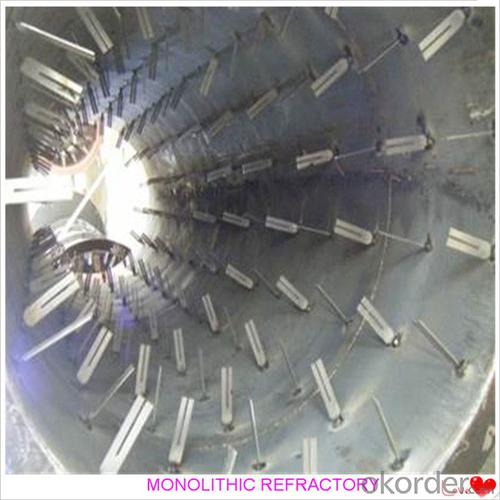

Product Picture:

- Q: How do monolithic refractories contribute to the overall efficiency of iron and steel production?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of iron and steel production. These refractories, which are made from a single material, provide exceptional thermal insulation, resistance to high temperatures, and excellent mechanical strength. By lining the furnaces, ladles, and other equipment used in the production process, monolithic refractories help in maintaining and regulating the required high temperatures for melting, refining, and shaping iron and steel. This insulation reduces heat loss, minimizes energy consumption, and ensures a more efficient and cost-effective production process. Additionally, the mechanical strength of monolithic refractories allows for better protection against wear and tear, resulting in increased equipment lifespan and reduced downtime for repairs and maintenance. Overall, the use of monolithic refractories significantly contributes to the efficiency, productivity, and sustainability of the iron and steel production industry.

- Q: What are the common failure mechanisms of monolithic refractories in the iron and steel industry?

- Common failure mechanisms of monolithic refractories in the iron and steel industry include: 1. Thermal spalling: Monolithic refractories are exposed to extreme temperature changes during the iron and steel production process. These rapid temperature fluctuations can cause the refractory material to expand and contract, leading to thermal stress and ultimately spalling. This failure mechanism is particularly common in areas where the refractory is exposed to high temperatures, such as in the hot face of a furnace. 2. Chemical attack: The iron and steel production process involves the use of various chemicals and molten metal, which can react with the refractory material over time. Chemical attack can cause the refractory to deteriorate, leading to cracks, erosion, and ultimately failure. Common culprits include slag, alkalis, sulfur, and other impurities present in the production environment. 3. Abrasion: The movement of materials, such as iron ore, coke, and fluxes, can cause abrasion on the refractory lining. This mechanical wear and tear can weaken the refractory material, leading to its failure. Abrasion is particularly prevalent in areas that experience high material flow rates or turbulence, such as in the taphole or launder systems. 4. Corrosion: Monolithic refractories can be subjected to corrosion from the gases, liquids, and solids present in the iron and steel production environment. Corrosion can occur due to the presence of oxygen, water vapor, and various chemical species, such as carbon monoxide and sulfur compounds. It can lead to the formation of corrosive products, such as oxides or sulfides, which degrade the refractory material over time. 5. Mechanical stress: Monolithic refractories may experience mechanical stress due to factors like thermal expansion and contraction, vibration, or mechanical impact. Excessive mechanical stress can cause cracks or fractures in the refractory lining, compromising its integrity and leading to failure. To mitigate these failure mechanisms, proper selection of refractory materials, regular inspection, and maintenance are crucial. Additionally, designing refractory linings considering the specific operational conditions and using appropriate installation techniques can help enhance their performance and lifespan in the iron and steel industry.

- Q: How are monolithic refractories used in the repair and maintenance of ladle and tundish covers?

- Monolithic refractories are commonly used in the repair and maintenance of ladle and tundish covers due to their excellent thermal resistance and durability. Ladles and tundishes are crucial components in the steelmaking process, and their covers play a vital role in the containment of molten metal and the prevention of heat loss. When ladle and tundish covers are subjected to high temperatures and thermal cycling, they can experience wear and tear, leading to cracks, spalling, or even complete failure. This is where monolithic refractories come into play. Monolithic refractories are unshaped refractory materials that can be easily molded and applied to the damaged areas of ladle and tundish covers. They can be cast, gunned, or sprayed onto the surface, allowing for quick and efficient repairs. These refractories are typically composed of a matrix material, such as alumina, silica, or magnesia, along with various additives and bonding agents. The specific composition depends on the application requirements and the severity of the operating conditions. The repair process begins by identifying the damaged areas of the ladle or tundish cover. Any loose or damaged refractory material is removed, and the surface is prepared for the application of the monolithic refractory. This may involve cleaning, roughening, or even preheating the surface, depending on the specific requirements. The monolithic refractory is then mixed with water or a suitable binder to form a workable consistency. It is then applied to the damaged areas using the appropriate method, such as casting or spraying. After application, the refractory material is allowed to dry and cure, typically through a controlled heating process. Once cured, the monolithic refractory forms a strong and durable lining that can withstand the high temperatures, thermal cycling, and chemical reactions that occur during ladle and tundish operation. It provides excellent thermal insulation, preventing heat loss and reducing energy consumption. Furthermore, monolithic refractories offer superior resistance to slag, metal penetration, and erosion, ensuring extended service life for ladle and tundish covers. They also have good thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or spalling. In summary, monolithic refractories are essential in the repair and maintenance of ladle and tundish covers due to their thermal resistance, durability, and ease of application. Their ability to withstand high temperatures, thermal cycling, and chemical reactions ensures the integrity and efficiency of ladle and tundish operations in the steelmaking industry.

- Q: How do monolithic refractories withstand high temperatures in iron and steel production?

- Monolithic refractories, which are tailored for iron and steel production, have the capability to endure the formidable temperatures involved. Unlike traditional brick refractories that are built brick by brick, monolithic refractories are made from a single piece or material. The resilience of monolithic refractories against high temperatures is due to their distinctive composition and structure. They are crafted from top-notch raw materials, such as alumina, magnesia, silica, and carbon, which possess high melting points and exceptional heat resistance. To shape and strengthen the monolithic refractory, it is commonly mixed with a binder like clay or cement. This binder assists in binding the refractory particles together and provides the necessary structure to withstand thermal stresses. Moreover, the mixture can include various additives to further enhance the refractory properties. Throughout the iron and steel production process, monolithic refractories encounter extreme temperatures, rapid heating and cooling cycles, and chemical reactions with molten metals and slag. Nevertheless, the unique composition and structure of monolithic refractories enable them to withstand these harsh conditions. The high melting point materials utilized in monolithic refractories prevent them from melting or deforming under the intense heat of iron and steel production. These materials exhibit excellent thermal conductivity, effectively transferring heat away from hot surfaces and preventing overheating and damage. Furthermore, the binders and additives in monolithic refractories enhance their resistance to thermal shock, which arises from sudden temperature changes. This resistance is vital in iron and steel production since the refractories are frequently exposed to extreme temperature differentials. Lastly, the monolithic nature of these refractories eliminates the presence of joints and gaps commonly found in traditional brick refractories. The absence of joints minimizes the risk of heat leakage and infiltration of molten metal or slag, ensuring a more efficient and durable lining. In conclusion, monolithic refractories are specifically engineered to endure the high temperatures involved in iron and steel production. Their composition, structure, and unique properties enable them to withstand extreme heat, rapid temperature changes, chemical reactions, and thermal stresses, making them essential components in the manufacturing of iron and steel.

- Q: How do monolithic refractories contribute to the overall productivity of iron and steel production?

- Monolithic refractories play a crucial role in enhancing the overall productivity of iron and steel production. These refractories are widely used in various applications such as furnaces, ladles, and tundishes, offering excellent thermal stability and resistance to chemical attacks. By providing a durable lining, monolithic refractories ensure longer campaigns and reduced downtime for repairs and maintenance. This leads to increased production efficiency, reduced energy consumption, and improved product quality, ultimately contributing to the overall productivity of iron and steel production.

- Q: How do monolithic refractories perform in reheating furnace applications?

- Monolithic refractories perform exceptionally well in reheating furnace applications due to their excellent thermal shock resistance, high temperature stability, and superior insulation properties. They are able to withstand the extreme temperatures and rapid temperature changes that occur during the reheating process, ensuring consistent and efficient heat distribution. Additionally, their flexible and easy-to-install nature makes them an ideal choice for lining the complex geometries of reheating furnaces, resulting in improved performance and extended service life.

- Q: How can the lifespan of monolithic refractories be extended?

- There are several measures that can be taken to extend the lifespan of monolithic refractories. To begin with, it is essential to ensure their proper installation. This involves following the guidelines provided by the manufacturer, using appropriate equipment and techniques, and ensuring correct curing and drying processes. By installing them correctly, the monolithic refractories become better equipped to withstand thermal stresses and chemical attacks, thus prolonging their lifespan. Regular maintenance is also crucial in extending the lifespan of monolithic refractories. This includes conducting routine inspections to identify any signs of wear, erosion, or cracking. Timely repairs or replacements should be carried out to prevent further damage. Moreover, applying protective coatings or sealants can help reduce erosion and chemical attacks, thereby enhancing the refractories' longevity. Another important aspect is implementing effective operating practices. This involves maintaining optimal operating conditions, such as controlling temperature fluctuations, to minimize thermal shocks and reduce the risk of spalling or cracking. Proper material selection is also key, as using refractories specifically designed for the intended application can increase their resistance to chemical attacks and extend their lifespan. Furthermore, ensuring proper handling and storage of monolithic refractories is essential. They should be stored in a dry, clean environment, away from moisture and extreme temperatures, to prevent premature degradation. Careful handling should be exercised, avoiding excessive impact or rough treatment that could cause damage. Lastly, it is beneficial to seek guidance from experienced professionals or consult refractory suppliers. Their expertise can provide valuable insights and guidance on best practices for extending the lifespan of monolithic refractories. By making informed decisions regarding installation, maintenance, and operating practices, the refractories' lifespan can be maximized and their performance optimized.

- Q: What are the factors affecting the thermal expansion of monolithic refractories?

- There are several factors that influence the thermal expansion of monolithic refractories. 1. Chemical Composition: The chemical composition of the refractory material plays a significant role in its thermal expansion. Different chemical elements and compounds have different coefficients of thermal expansion. For example, materials containing high levels of silica tend to have lower coefficients of thermal expansion compared to materials with higher concentrations of alumina. 2. Particle Size: The particle size distribution of the refractory material can affect its thermal expansion. Smaller particle sizes tend to result in higher thermal expansion due to increased surface area and greater contact between particles. 3. Temperature: The temperature at which the monolithic refractory is exposed can greatly impact its thermal expansion. As the temperature increases, the kinetic energy of the particles increases, causing them to move more vigorously and expand. Different refractory materials have different temperature ranges at which they exhibit significant expansion. 4. Thermal History: The thermal history of the refractory material, including its heating and cooling cycles, can influence its thermal expansion behavior. Repeated heating and cooling cycles can induce microstructural changes in the material, affecting its thermal expansion properties. 5. Porosity: The porosity of the monolithic refractory can affect its thermal expansion. Higher porosity generally leads to higher thermal expansion due to the presence of voids and gaps within the material. 6. Binder Content: Monolithic refractories often contain binders that hold the particles together. The type and amount of binder used can impact the thermal expansion of the refractory. Different binders have different coefficients of thermal expansion, which can influence the overall expansion behavior of the material. 7. Thermal Shock: Rapid temperature changes, such as during quenching or exposure to alternating heating and cooling, can cause thermal shock in the refractory material. This can lead to cracks, spalling, and changes in the thermal expansion behavior. Understanding these factors is crucial in selecting the appropriate monolithic refractory material for specific applications, as the thermal expansion characteristics can directly impact the performance and longevity of the refractory in high-temperature environments.

- Q: How do monolithic refractories perform in electric arc furnace roof applications?

- Monolithic refractories are highly effective in electric arc furnace (EAF) roof applications due to their unique properties and characteristics. These refractories, which are composed of a single, solid material, offer several advantages in this specific application. Firstly, monolithic refractories provide excellent thermal insulation, which is crucial in EAF roof applications. The intense heat generated in the furnace can cause structural damage to traditional brick refractories, but monolithic refractories have a higher resistance to thermal shock, reducing the risk of cracking and spalling. This allows them to maintain their integrity and insulation properties even in extreme temperature conditions. Moreover, monolithic refractories have high strength and abrasion resistance, ensuring their durability and longevity in EAF roof applications. The roof of an electric arc furnace is exposed to harsh conditions, including the impact of scrap materials and the erosive effect of molten metal and slag. Monolithic refractories are designed to withstand these challenges, offering superior resistance to mechanical wear and erosion. Another advantage of monolithic refractories is their ease of installation. Unlike traditional brick refractories, which require time-consuming and complex installation processes, monolithic refractories can be applied quickly and efficiently. They can be cast, gunned, or sprayed onto the roof surface, conforming to any shape or contour, thus reducing downtime during installation or repair. Furthermore, monolithic refractories provide increased energy efficiency in EAF roof applications. Their superior insulation properties minimize heat loss, resulting in reduced energy consumption and cost savings. This is particularly important for electric arc furnaces, as they rely on high temperatures to melt and process metals, and any heat loss can significantly impact the efficiency and productivity of the furnace. In conclusion, monolithic refractories are highly suitable for electric arc furnace roof applications due to their exceptional thermal insulation, strength, abrasion resistance, ease of installation, and energy efficiency. These refractories offer significant advantages over traditional brick refractories, ensuring optimal performance and prolonged service life in the demanding environment of an electric arc furnace.

- Q: How do monolithic refractories improve energy efficiency in the iron and steel industry?

- Various mechanisms are employed by monolithic refractories to enhance energy efficiency in the iron and steel industry. To begin with, these refractories possess exceptional insulation properties that effectively minimize heat loss during production. This results in a higher retention of heat within the furnace, thereby increasing energy efficiency. Furthermore, monolithic refractories exhibit low thermal conductivity, facilitating improved heat transfer within the furnace. This allows for efficient distribution of the heat generated during production, enabling optimal temperature control and reducing energy wastage. Additionally, monolithic refractories demonstrate high resistance to thermal shock and corrosion, which are common challenges faced in the iron and steel industry. By enduring extreme temperatures and chemical reactions, these refractories prevent premature wear and tear, consequently reducing the need for frequent repairs and replacements. This not only conserves energy but also minimizes downtime, leading to enhanced productivity and energy efficiency. Moreover, the utilization of monolithic refractories enables better furnace design and optimization. Their flexibility permits the creation of bespoke shapes and linings that cater to specific furnace requirements, resulting in improved heat transfer and combustion efficiency. This customized approach promotes energy savings by maximizing fuel utilization and reducing emissions. Lastly, monolithic refractories possess a longer lifespan compared to conventional brick refractories. This prolonged durability reduces the frequency of refractory replacements, subsequently lowering the energy consumption associated with the manufacturing and installation of new refractories. Overall, monolithic refractories play a significant role in enhancing energy efficiency in the iron and steel industry by reducing heat loss, improving heat transfer, withstanding thermal shock and corrosion, enabling better furnace design, and increasing refractory lifespan. Their usage not only saves energy but also enhances productivity and sustainability within the industry.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Castable for Fireplace and Industrial Furnace Cement Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords