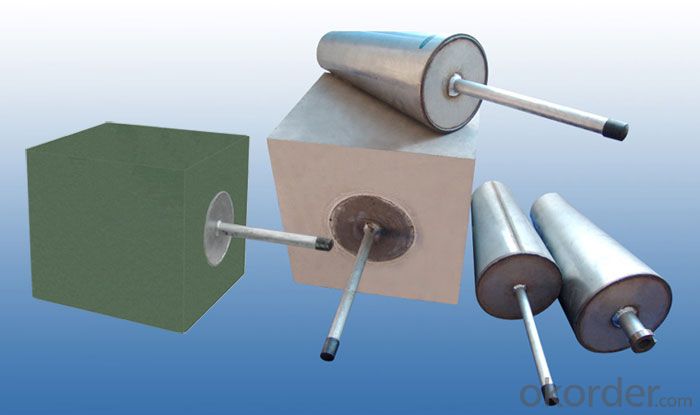

Refractory Brick purging plug for Ladles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High quality steel ladle purging plug for steel making

Company profile

We have many years manufacturing experience in producing all types of electric furnace refractories, ladle refractories, tundish refractories, metallurgy furnace burden refractory insulating products, industrial furnace refractories, etc,

purging plug Raw materials

Ladle permeable brick has been in the leading position in domestic and abroad over years. We have developed the series of corundum, chromium corundum, low silicon chromium corundum and corundum spinel one after another.

Customized purging plug

They can be designed and produced types of straight hole, directional slit, directional labyrinth, girth shape and interior and exterior integral split etc according to users’ request. Permeable flow rate of products can be designed upon customers’ request and can be adjusted in a wide range. The blowing opening rate is high.

purging plug Characters

Continuous casting Ladle Porous Block

High alumina and MgO content

High stability.

Thermal shock resisitance.

High life span

purging plug Physical and chemical indexes

Brand | TQZ-1 | TQZ-2 | |

Chemical composition/%,≥ | Al2O3+Cr2O3 | 92 | |

Al2O3+MgO | 92 | ||

Bulk density g/cm³ ≥ | 3 | 3 | |

Crushing strength /Mpa≥ | 1500°C×3h | 100 | 80 |

Modulus of rupture/Mpa≥ | 1500°C×3h | 20 | 15 |

Firing linear change % | 1500°C×3h | 0~+0.3 | 0~+0.4 |

Penetration gas flux (0.4Mpa)/m³ h-1 | 12~60 | 12~60 | |

Factory productivity

Based on 180,000 TON annual productivity and advanced production equipment, we have build deep cooperation relationship with Vietnam, Nigeria, Tailand, Saudi Arabia, Iran, Turkey, etc.

- Q: How do monolithic refractories withstand high temperatures and thermal cycling?

- Monolithic refractories withstand high temperatures and thermal cycling due to their unique composition and structure. They are made from a single piece or material, which eliminates joints or seams that could be vulnerable to thermal stress. Additionally, they are designed with a high thermal conductivity and low thermal expansion, allowing them to expand and contract without cracking or spalling. This enables them to maintain their integrity and mechanical strength even under extreme temperature fluctuations, making them highly durable and suitable for applications in industries such as steel, cement, and petrochemical.

- Q: What are the challenges in using monolithic refractories in the iron and steel industry?

- The iron and steel industry faces significant challenges when it comes to using monolithic refractories. One of these challenges is the fact that monolithic refractories are more prone to thermal shock compared to traditional brick refractories. Unlike brick refractories, which are made from multiple materials and have strong structural integrity, monolithic refractories are made from a single material, which makes them more susceptible to cracking and failure when exposed to rapid changes in temperature. Another challenge lies in achieving consistent and uniform application of monolithic refractories. While brick refractories can be precisely shaped and fitted into specific areas, monolithic refractories are typically applied as a mortar-like mixture that is poured or sprayed into place. This process is more complex and requires skilled operators to ensure proper application and adhesion. Additionally, monolithic refractories have a shorter lifespan compared to brick refractories. They are more vulnerable to erosion and wear, especially in high-temperature environments and when exposed to harsh chemicals and slag. This means that regular maintenance and replacement of monolithic refractories are necessary, leading to increased downtime and costs for the iron and steel industry. Furthermore, selecting and customizing monolithic refractories can be challenging. The iron and steel industry has diverse operating conditions and requirements, making it difficult to find the right monolithic refractory composition and design that can withstand the specific demands of each application. Factors such as temperature, chemical composition, and mechanical stress must be carefully considered. In conclusion, although monolithic refractories offer advantages such as easy installation and versatility, their susceptibility to thermal shock, difficulty in achieving uniform application, shorter lifespan, and the need for customized selection present challenges for their effective use in the iron and steel industry.

- Q: How do monolithic refractories contribute to the overall efficiency of ladle slagging operations?

- Monolithic refractories play a vital role in enhancing the overall efficiency of ladle slagging operations, which involve removing impurities from molten metal in a ladle before pouring it into molds or further processing. One of the primary benefits of monolithic refractories is their capacity to withstand high temperatures, a crucial factor in ladle slagging operations. The refractory lining in the ladle must endure the intense heat generated by the molten metal and slag, as well as the chemical reactions occurring during the process. By possessing high thermal stability, monolithic refractories prevent the lining from cracking or deteriorating, thus ensuring the integrity of the ladle and maintaining its efficiency. Furthermore, monolithic refractories offer excellent resistance against chemical erosion and corrosion. In the ladle slagging process, the molten metal and slag may contain impurities and aggressive chemicals such as sulfur, phosphorus, and other oxides. These substances can attack and degrade the lining of the ladle, compromising its efficiency. However, monolithic refractories are specifically designed to withstand these chemical attacks, thereby prolonging the lifespan of the ladle and reducing the need for frequent repairs or replacements. Moreover, monolithic refractories possess exceptional thermal insulation properties. Precise temperature control is essential in ladle slagging operations to facilitate desired chemical reactions and efficient impurity removal. The thermal insulation provided by monolithic refractories helps maintain a consistent temperature within the ladle, preventing heat loss and facilitating optimal slagging conditions. Additionally, this insulation minimizes energy consumption and improves the overall energy efficiency of the ladle slagging process. In conclusion, monolithic refractories make significant contributions to the overall efficiency of ladle slagging operations. Their ability to endure high temperatures, resist chemical erosion, and provide thermal insulation ensures the integrity and longevity of the ladle. By reducing the need for frequent repairs and enabling precise temperature control, monolithic refractories optimize the slagging process, leading to enhanced productivity and cost-effectiveness.

- Q: How do monolithic refractories contribute to the overall efficiency of steel ladle operations?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of steel ladle operations. These refractories are engineered materials that are installed as a single, unbroken structure within the ladle. They offer numerous benefits that directly contribute to the efficiency of the steel ladle operations. Firstly, monolithic refractories are known for their excellent thermal insulation properties. They have low thermal conductivity, which means they can effectively retain and contain heat within the ladle. This insulation property helps in maintaining the desired temperature of the molten steel, preventing heat loss during transportation and reducing the need for frequent reheating. By minimizing heat loss, monolithic refractories enable more efficient use of energy resources, resulting in cost savings and improved productivity. Additionally, monolithic refractories exhibit high refractoriness, which refers to their ability to withstand high temperatures without losing their structural integrity. This characteristic is vital in steel ladle operations, as the ladles are exposed to extreme temperatures during the steelmaking process. The high refractoriness of monolithic refractories ensures that they can withstand the intense heat and prevent any damage or failure of the ladle lining. This durability translates into reduced downtime and maintenance requirements, leading to increased operational efficiency. Moreover, monolithic refractories offer excellent resistance to chemical attack. The ladles used in steelmaking are in contact with various corrosive substances, such as molten metals, slag, and fluxes. The chemical resistance of monolithic refractories prevents them from reacting with these substances, ensuring the integrity and longevity of the ladle lining. This resistance to chemical attack reduces the frequency of repairs and replacements, minimizing downtime and improving the overall efficiency of ladle operations. Furthermore, the installation of monolithic refractories is relatively quick and straightforward compared to traditional brick linings. This ease of installation saves time and labor costs, allowing for faster turnaround between ladle operations. It enables steel manufacturers to optimize their production schedules and enhance overall operational efficiency. In conclusion, monolithic refractories contribute significantly to the overall efficiency of steel ladle operations. Their excellent thermal insulation properties, high refractoriness, resistance to chemical attack, and ease of installation all play vital roles in improving energy efficiency, reducing downtime, and enhancing productivity. By choosing monolithic refractories, steel manufacturers can achieve optimized ladle performance and ultimately improve their overall steelmaking process.

- Q: How do monolithic refractories prevent thermal radiation in the iron and steel industry?

- Monolithic refractories prevent thermal radiation in the iron and steel industry by providing a high level of insulation. They are specifically designed to withstand high temperatures and reduce heat transfer through radiation. By forming a protective barrier around the furnaces and other equipment, monolithic refractories minimize the loss of heat through thermal radiation, thereby improving energy efficiency and reducing energy consumption in the iron and steel production process.

- Q: What are the common failure mechanisms of monolithic refractories?

- Monolithic refractories commonly fail due to thermal spalling, chemical attack, erosion, and mechanical stress. Thermal spalling arises from abrupt temperature changes, causing the refractory material to crack and break. This can result from thermal shock or cyclic heating and cooling. Chemical attack occurs when aggressive chemicals or gases interact with the refractory material, degrading its lining. This can lead to the formation of new compounds or the dissolution of the refractory material, weakening its structure and reducing its resistance to further chemical attack. Erosion is another prevalent failure mechanism, particularly in scenarios where the refractory lining is exposed to high-speed gas or liquid flows. The abrasive action of the medium can gradually erode the refractory material, causing thinning and eventual failure of the lining. Mechanical stress, such as thermal expansion or contraction mismatch, can also lead to failure in monolithic refractories. Rapid temperature changes can result in differential expansion or contraction, leading to the development of cracks and fractures in the lining. To mitigate these failure mechanisms, several techniques can be utilized. These include careful material selection based on operating conditions, meticulous design to minimize thermal gradients, application of protective coatings, and regular inspection and maintenance to promptly detect and address signs of failure or degradation.

- Q: How do monolithic refractories improve the performance and efficiency of iron and steel production?

- Monolithic refractories play a crucial role in improving the performance and efficiency of iron and steel production. These specialized materials are designed to withstand extreme temperatures, chemical reactions, and mechanical stresses, making them ideal for use in high-temperature industrial processes. One of the key ways in which monolithic refractories enhance performance is by providing a protective lining in furnaces, kilns, and other equipment used in iron and steel production. Due to their superior heat resistance, they protect the underlying structure from the intense heat and prevent any detrimental effects on the equipment. This results in reduced downtime, longer service life, and ultimately, increased overall efficiency. Monolithic refractories also ensure better thermal efficiency in the production process. By minimizing heat losses, these materials help to maintain a stable and uniform temperature distribution, thereby improving the energy efficiency of the system. This is particularly important in iron and steel production, where precise temperature control is crucial for achieving the desired metallurgical properties of the final product. Furthermore, monolithic refractories offer excellent resistance to chemical corrosion, erosion, and slag attacks. They act as a barrier between the molten metal and the refractory lining, preventing undesirable reactions and material degradation. This helps to maintain the integrity of the furnace lining, reducing the need for frequent repairs or replacements. Consequently, it leads to increased productivity and cost savings in the long run. Another advantage of monolithic refractories is their ability to be easily shaped, repaired, or replaced. Unlike traditional brick refractories, which require extensive labor and time-consuming installation, monolithic refractories can be applied in a more flexible and efficient manner. Their flexible nature allows for easy repair of damaged areas, minimizing downtime and ensuring continuous production. In summary, the use of monolithic refractories significantly enhances the performance and efficiency of iron and steel production. These materials provide a protective lining, improve thermal efficiency, resist chemical corrosion, and offer easy installation and repair options. By optimizing the production process, monolithic refractories contribute to higher productivity, reduced downtime, and increased cost-effectiveness in the iron and steel industry.

- Q: What are the limitations of monolithic refractories in high-temperature applications?

- Monolithic refractories have certain limitations when used in high-temperature applications. One major limitation is their susceptibility to thermal shock. Monolithic refractories lack the structural stability and resistance to sudden temperature changes compared to other refractory materials. Additionally, their relatively low thermal conductivity can lead to uneven heat distribution and potential hotspots, affecting the overall performance and longevity of the refractory lining. Another limitation is their susceptibility to chemical attack by certain aggressive environments, which can lead to accelerated deterioration and reduced lifespan. Overall, while monolithic refractories offer certain advantages in terms of installation flexibility and ease of maintenance, their limitations in terms of thermal shock resistance, thermal conductivity, and chemical resistance must be considered in high-temperature applications.

- Q: What are the advantages of using monolithic refractories in electric arc furnaces?

- There are several advantages of using monolithic refractories in electric arc furnaces. Firstly, monolithic refractories offer superior thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or failing. This is crucial in electric arc furnaces where the temperature can fluctuate significantly during the melting process. Additionally, monolithic refractories have excellent corrosion resistance, which is essential in electric arc furnaces that often come into contact with corrosive molten metals and slag. They can withstand the corrosive effects, ensuring longer service life and reduced maintenance costs. Moreover, monolithic refractories provide ease of installation and repair. Unlike traditional bricks, they can be easily shaped and applied in various furnace designs, minimizing installation time and labor costs. In case of any damage, they can also be easily patched or replaced, allowing for quicker repairs and reduced downtime. Lastly, monolithic refractories offer improved energy efficiency due to their lower thermal conductivity. This means that less heat is lost to the surroundings, resulting in higher operational efficiency and reduced energy consumption. Overall, the advantages of using monolithic refractories in electric arc furnaces include superior thermal shock and corrosion resistance, ease of installation and repair, and improved energy efficiency, making them a preferred choice for these high-temperature industrial applications.

- Q: What are the key properties of pumpable refractories used for monolithic refractory applications?

- The key properties of pumpable refractories used for monolithic refractory applications include high flowability, good workability, excellent bonding strength, and high resistance to thermal shock. These pumpable refractories should also possess good pumpability and be able to withstand the intense heat and mechanical stress in the application environment. Additionally, they should have low water demand, high chemical resistance, and the ability to maintain their properties even after exposure to high temperatures.

Send your message to us

Refractory Brick purging plug for Ladles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords