Monolithic Refractories for Iron and Steel Industry - Dense Castable for Fireside and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

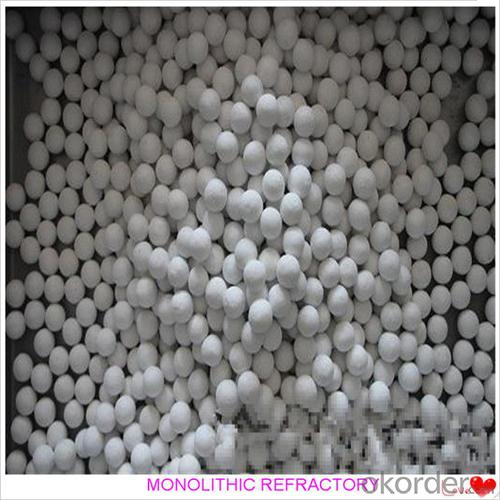

Dense Castable for Fireplaces and Industrial Iron and Steel Furnaces

Product Description:

Dense castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by clients. Castables use high purity raw materials and additives as the main material, and are made with superfine powder adding technology.

Product Features:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, and also excellent working ability. If should be used with the same material products.

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: How do monolithic refractories contribute to energy efficiency in iron and steel production?

- Monolithic refractories play a crucial role in enhancing energy efficiency in iron and steel production processes. These refractories are unshaped materials that are used to line the various components of furnaces, kilns, and other high-temperature equipment involved in the production of iron and steel. One way monolithic refractories contribute to energy efficiency is by providing excellent insulation. These materials have low thermal conductivity, which means they effectively reduce heat transfer from the furnace or kiln to the surrounding environment. By minimizing heat loss, monolithic refractories help maintain high temperatures within the production units, which in turn reduces the energy required to sustain the desired operating conditions. Furthermore, monolithic refractories offer superior resistance to thermal shock and wear, ensuring the longevity of the lining materials. This durability reduces the need for frequent repairs and replacements, leading to less downtime and increased operational efficiency. As a result, energy is conserved since the production units can continuously operate at optimal temperatures without interruptions. In addition, monolithic refractories have excellent resistance to chemical reactions, corrosion, and erosion caused by molten metals and slag. This resistance reduces the formation of cracks and defects in the lining, which can compromise the insulation and increase heat loss. By maintaining a robust and intact lining, monolithic refractories contribute to energy efficiency by minimizing heat escape and ensuring the efficient utilization of energy for the iron and steel production processes. Moreover, the use of monolithic refractories allows for design flexibility in the construction of furnaces and kilns. Their ability to be shaped and applied in various configurations enables the creation of optimized lining structures that enhance heat transfer and combustion efficiency. This flexibility empowers engineers and operators to design and modify the production units to maximize energy efficiency and minimize energy wastage. Overall, monolithic refractories contribute significantly to energy efficiency in iron and steel production by providing excellent insulation, durability, resistance to thermal and chemical degradation, and design flexibility. By reducing heat loss, minimizing repairs and replacements, and optimizing heat transfer, these refractories play a vital role in conserving energy and improving the overall sustainability of the iron and steel industry.

- Q: How do monolithic refractories resist high temperatures?

- Monolithic refractories are designed to resist high temperatures due to their unique composition and structure. These refractories are made from a single piece or material, unlike traditional refractory bricks that are composed of multiple pieces. The main reason why monolithic refractories can resist high temperatures is their high melting point. These refractories are made from materials such as alumina, silica, and magnesia, which have high melting points ranging from 1650°C to 2000°C. This means that they can withstand extreme temperatures without undergoing significant deformation or melting. Furthermore, monolithic refractories possess excellent thermal stability. They have low thermal conductivity, which means they can effectively insulate against heat transfer. This property allows the refractories to maintain their structural integrity even when exposed to rapid temperature changes or thermal shocks. In addition, the monolithic nature of these refractories provides them with enhanced resistance to thermal stress. Unlike traditional refractory bricks, monolithic refractories do not have joints or seams that can be vulnerable to thermal expansion and contraction. This makes them more resistant to cracking or spalling when subjected to high temperatures. Moreover, monolithic refractories can form a protective layer or slag on their surface when exposed to high temperatures. This slag acts as a barrier and prevents direct contact between the refractory material and the hot gases or molten metals, reducing the risk of chemical reactions or corrosion. Overall, the combination of high melting point, thermal stability, resistance to thermal stress, and the ability to form protective slag makes monolithic refractories highly effective in resisting high temperatures. They are widely used in various industries, including steel, cement, glass, and petrochemical, where they are exposed to extreme heat conditions.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish preheating furnaces?

- Monolithic refractories greatly contribute to the efficiency of ladle and tundish preheating furnaces. These refractories, made from a single material, are easily installed, repaired, and replaced, making them versatile and cost-effective. The efficiency of these furnaces is improved thanks to the outstanding thermal insulation properties of monolithic refractories. With low thermal conductivity, they effectively retain heat and prevent its escape. This insulation capability ensures an efficient preheating process, reducing energy consumption and costs by minimizing heat loss. Additionally, monolithic refractories possess high thermal shock resistance, which is crucial in ladle and tundish preheating furnaces. These furnaces experience rapid temperature changes during the pouring of molten metal, which can lead to cracking or failure of traditional refractories. However, monolithic refractories are specifically designed to withstand thermal shock, remaining intact and maintaining their insulating properties even in extreme conditions. This durability reduces downtime and maintenance requirements, thus enhancing overall efficiency. Furthermore, monolithic refractories provide a seamless and uniform lining surface, improving heat transfer within the furnace. The absence of joints or seams reduces the risk of heat leakage and ensures even distribution of heat throughout the lining. This promotes uniform heating of the ladle or tundish, allowing for more efficient preheating and better temperature control. In conclusion, the use of monolithic refractories in ladle and tundish preheating furnaces results in improved efficiency due to their exceptional thermal insulation properties, high thermal shock resistance, and ability to provide a seamless and uniform lining. These refractories minimize heat loss, reduce energy consumption, and enhance the overall performance of the preheating process.

- Q: What types of monolithic refractories are commonly used in the iron and steel industry?

- Due to their exceptional resistance to extreme temperatures and mechanical stresses, various types of monolithic refractories are widely used in the iron and steel industry. These refractories play a crucial role in lining furnaces, ladles, and other equipment used in the production of iron and steel. One commonly employed monolithic refractory in this industry is castable refractory. It is a blend of refractory aggregates, binders, and additives that can be poured or cast into different shapes and sizes. Castable refractories are versatile and easy to install, making them suitable for lining large furnaces and ladles. Additionally, they offer excellent resistance to thermal shocks and provide good thermal insulation. Another type of monolithic refractory utilized in the iron and steel industry is plastic refractory. It comprises a high-alumina refractory aggregate mixed with a bonding agent, typically clay. Plastic refractories possess high plasticity and can be easily shaped by hand or with a trowel. They are commonly used for repairing and patching in furnaces and ladles. Ramming refractories are also frequently employed in the iron and steel industry. These refractories consist of granular refractory materials blended with a binder. They are installed by forcefully ramming the mixture into the desired shape using either a pneumatic hammer or manual ramming tools. Ramming refractories offer exceptional resistance to abrasion and erosion, making them suitable for lining the bottoms of furnaces and other areas subjected to intense mechanical wear. Lastly, gunning refractories find wide application in the iron and steel industry. Gunning refractories are composed of fine refractory powders mixed with water or a bonding agent. They are applied using a gunning machine, which propels the refractory material onto the surface that requires lining. Gunning refractories are commonly used for repairing and maintaining the linings of ladles, tundishes, and other equipment. In conclusion, the iron and steel industry heavily relies on a variety of monolithic refractories, including castables, plastics, rammings, and gunnings, to ensure the reliable and efficient operation of their equipment in high-temperature environments. These refractories offer outstanding thermal insulation, resistance to thermal shocks, and mechanical strength, which are essential for the production of iron and steel.

- Q: How do monolithic refractories handle thermal expansion and contraction?

- Monolithic refractories are designed to handle the challenges of thermal expansion and contraction. These materials are composed of a single solid structure, as opposed to the traditional brick or tile forms of refractories. This unique composition allows monolithic refractories to better accommodate the thermal stresses associated with temperature changes. One way that monolithic refractories handle thermal expansion and contraction is through their ability to withstand high temperatures. These materials are typically engineered to have a high melting point, allowing them to maintain their structural integrity even under extreme heat conditions. This property helps to prevent the refractory from cracking or disintegrating due to thermal expansion. In addition, monolithic refractories often contain a binder or bonding agent that helps to hold the refractory particles together. This binder can be formulated to have a certain degree of flexibility, allowing the material to expand and contract without cracking or breaking. This flexibility helps to absorb the stresses caused by thermal expansion and contraction, ensuring the longevity and performance of the refractory. Furthermore, monolithic refractories can be applied in a way that allows for expansion and contraction. These materials can be installed with joints or gaps between sections, which can accommodate the movement caused by temperature changes. This technique, known as joint design or expansion joint systems, allows the refractory to expand and contract without causing damage to the overall structure. Overall, monolithic refractories are designed to handle thermal expansion and contraction by withstanding high temperatures, incorporating flexible binders, and using joint design techniques. These properties enable them to maintain their structural integrity and performance in extreme heat conditions, making them a reliable choice for applications that require resistance to thermal stress.

- Q: How do monolithic refractories perform in blast furnace taphole applications?

- Monolithic refractories perform exceptionally well in blast furnace taphole applications due to their unique characteristics and properties. Firstly, monolithic refractories are known for their superior thermal resistance. Blast furnace tapholes are exposed to extremely high temperatures and thermal shocks, making it essential to have a refractory material that can withstand these conditions. Monolithic refractories have high refractoriness, meaning they can maintain their structural integrity even at elevated temperatures, ensuring the taphole remains functional. Secondly, monolithic refractories have excellent erosion and corrosion resistance. In blast furnace taphole applications, the refractory material is constantly exposed to molten metal, slag, and gases that can cause erosion and chemical reactions. Monolithic refractories are designed to resist these aggressive environments, minimizing wear and extending the service life of the taphole. Furthermore, monolithic refractories offer good thermal conductivity and insulation properties. This is crucial for blast furnace tapholes as they need to maintain a consistent and controlled flow of molten metal. The refractory material must be able to transfer heat efficiently while also providing insulation to prevent excessive heat loss, ensuring optimal performance and productivity of the blast furnace. Additionally, monolithic refractories are easy to install and repair. Blast furnace tapholes require regular maintenance due to the harsh conditions they are subjected to. Monolithic refractories can be easily shaped and applied, allowing for quick repairs or replacement of damaged areas. This reduces downtime and increases the operational efficiency of the blast furnace. In summary, monolithic refractories are highly suitable for blast furnace taphole applications due to their excellent thermal resistance, erosion and corrosion resistance, good thermal conductivity and insulation properties, as well as ease of installation and repair. These characteristics make them a reliable and effective choice for maintaining the functionality and performance of blast furnace tapholes.

- Q: What are the advantages of using plastic refractories in the iron and steel industry?

- There are several advantages of using plastic refractories in the iron and steel industry. Firstly, plastic refractories offer excellent thermal insulation properties. They have low thermal conductivity, which means they can effectively retain heat and prevent excessive heat loss during the manufacturing process. This is crucial in the iron and steel industry as maintaining high temperatures is essential for the proper functioning of furnaces and other equipment. Secondly, plastic refractories have superior resistance to chemical attack and corrosion. They can withstand exposure to various chemicals, including molten metals and slag, without deteriorating or losing their structural integrity. This is especially important in the iron and steel industry, where materials come into contact with highly corrosive substances on a regular basis. Another advantage of plastic refractories is their ease of installation and repair. Unlike other refractory materials, plastic refractories can be easily shaped and molded into the desired form, allowing for precise fitting and quick installation. Additionally, they can be easily repaired or patched in case of damage or wear, which reduces downtime and maintenance costs. Furthermore, plastic refractories exhibit good mechanical strength and abrasion resistance. This enables them to withstand the physical stresses and mechanical forces present in the iron and steel industry, such as vibrations, impacts, and mechanical loading. Their high resistance to wear and tear ensures longevity and reduces the need for frequent replacements. Lastly, plastic refractories have a high thermal shock resistance. They can withstand rapid temperature changes without cracking or spalling. This is beneficial in the iron and steel industry, where materials are subjected to extreme temperature differentials, such as during the heating and cooling cycles of furnaces. In conclusion, the advantages of using plastic refractories in the iron and steel industry include excellent thermal insulation, resistance to chemical attack, ease of installation and repair, good mechanical strength, abrasion resistance, and high thermal shock resistance. These properties make plastic refractories an ideal choice for various applications in this industry, ensuring efficient and reliable operations.

- Q: What are the key innovations in monolithic refractories for the iron and steel industry?

- Some key innovations in monolithic refractories for the iron and steel industry include the development of advanced materials such as low cement castables, gunning mixes, and shotcretes. These materials offer improved resistance to thermal shock, increased strength, and enhanced erosion resistance, thereby extending the service life of refractory linings in high-temperature environments. Additionally, the introduction of monolithic refractory installation techniques such as robotic application and advanced spraying technologies has improved efficiency and reduced downtime during maintenance and repair operations.

- Q: What are the common challenges faced by monolithic refractories in the iron and steel industry?

- The iron and steel industry heavily relies on monolithic refractories, which have a vital role in various applications like lining furnaces, ladles, and tundishes. However, these materials encounter common challenges in this industry. Thermal shock is a major challenge. Monolithic refractories undergo extreme temperature changes, especially during start-up and shut-down phases. This rapid heating and cooling can cause thermal stress, leading to cracking and spalling. To combat this, refractory manufacturers create high-quality monolithic materials with enhanced thermal shock resistance. Corrosion is another significant challenge. The iron and steel industry exposes refractory linings to aggressive materials like molten metal, slag, and gases, which chemically attack them. This corrosion results in material degradation, erosion, and reduced service life. To address this, specialized monolithic refractories with excellent corrosion resistance are used, often containing additives that can withstand the corrosive environment. Abrasion is also a common challenge faced by monolithic refractories in this industry. The movement of raw materials, molten metal, and slag causes mechanical wear on the refractory lining, leading to material loss and compromised performance. Refractory manufacturers develop abrasion-resistant monolithic materials that can withstand intense wear and tear, ensuring extended service life. Moreover, good thermal conductivity is often required in the iron and steel industry. This is crucial for efficient heat transfer and maintaining optimal operating conditions. Achieving the right balance between thermal conductivity and mechanical strength can be challenging, as refractories with high thermal conductivity often have lower mechanical strength. Therefore, selecting the appropriate monolithic refractory with desired thermal conductivity properties is crucial for optimal performance. Lastly, installation and maintenance present challenges for monolithic refractories. The application of these refractories requires skilled personnel and careful installation techniques due to their liquid or semi-liquid nature. Additionally, regular maintenance and repairs are necessary to ensure the refractory lining's longevity and performance. Regular inspections, repairs, and proper curing techniques are vital to mitigate these challenges and optimize refractory performance. In conclusion, monolithic refractories in the iron and steel industry face challenges such as thermal shock, corrosion, abrasion, thermal conductivity, and installation/maintenance. Addressing these challenges through the development of specialized refractory materials and employing proper installation and maintenance techniques are crucial for ensuring efficient and reliable performance in this demanding industry.

- Q: How do monolithic refractories improve the durability of furnace linings?

- The durability of furnace linings is significantly enhanced by the unique characteristics and properties of monolithic refractories. Unlike traditional brick refractories, which are made up of individual bricks or tiles, monolithic refractories consist of a single, homogeneous structure. A key advantage of monolithic refractories is their ability to eliminate joints and seams, which are weak points in traditional brick refractories. These joints can lead to cracks and failures due to thermal expansion and contraction. In contrast, monolithic refractories are poured or gunned into place, creating a seamless lining that minimizes the potential for cracks. This seamless structure increases the durability of the lining and reduces its susceptibility to thermal stress. In addition, monolithic refractories exhibit excellent thermal shock resistance, which is crucial for furnace linings that experience rapid and extreme temperature changes. The monolithic structure allows for better heat transfer and distribution, preventing localized hotspots that can cause thermal shock and lining failure. This enhanced thermal shock resistance enables the furnace lining to withstand repeated heating and cooling cycles without significant damage, thus improving its overall durability. Furthermore, monolithic refractories offer superior resistance to erosion and corrosion. Furnace linings are often exposed to harsh chemicals, molten metals, and abrasive materials, which can cause erosion and corrosion over time. Monolithic refractories are specifically designed to resist these corrosive agents, protecting the lining from chemical attacks and physical wear. This resistance ensures a longer lifespan for the furnace lining and reduces the need for frequent repairs or replacements. Moreover, monolithic refractories possess better insulation properties compared to traditional brick refractories. They have lower thermal conductivity, meaning that heat transfer through the lining is minimized. This insulation property helps to maintain a more stable and uniform temperature within the furnace, reducing thermal stress on the lining and contributing to its longevity. To summarize, monolithic refractories enhance the durability of furnace linings by eliminating joints and seams, improving thermal shock resistance, providing erosion and corrosion resistance, and offering superior insulation properties. These materials are specifically engineered to withstand the extreme conditions inside furnaces, ensuring a longer lifespan for the lining and reducing maintenance costs in the long term.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Dense Castable for Fireside and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords