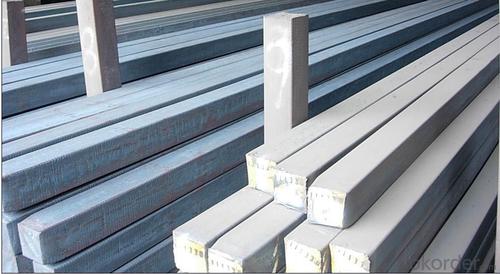

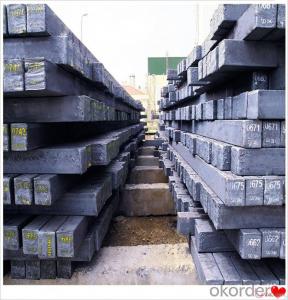

Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different methods of steel billet surface coating?

- There are several methods of steel billet surface coating that are commonly used in various industries. These methods aim to enhance the durability, corrosion resistance, and appearance of the steel billets. Some of the different methods of steel billet surface coating include: 1. Hot-dip galvanizing: This method involves immersing the steel billets in a bath of molten zinc. The zinc forms a protective layer on the surface of the steel, providing excellent corrosion resistance. Hot-dip galvanizing is widely used in construction, automotive, and infrastructure industries. 2. Electroplating: In this method, an electric current is used to deposit a thin layer of metal, such as chromium or nickel, onto the surface of the steel billets. Electroplating improves the appearance of the steel and provides a protective coating against corrosion. 3. Powder coating: Powder coating involves electrostatically spraying a dry powder onto the surface of the steel billets. The powder is then cured using heat, which forms a hard, durable, and attractive coating. Powder coating provides excellent resistance to impact, corrosion, and chemicals. 4. Painting: Steel billets can be coated with paint using various techniques such as spraying, dipping, or brushing. Paint coatings not only enhance the appearance of the steel but also provide protection against corrosion and weathering. 5. Thermal spray coating: This method involves projecting molten or semi-molten materials onto the surface of the steel billets. The materials can be metals, ceramics, or polymers, which form a coating upon solidification. Thermal spray coatings provide excellent corrosion resistance, wear resistance, and thermal insulation. 6. Anodizing: Anodizing is commonly used for aluminum, but it can also be applied to steel billets. In this process, the steel billets are immersed in an electrolyte solution and subjected to an electric current. This creates a controlled oxidation reaction on the surface, forming a protective layer of oxide. Anodizing improves the corrosion resistance and appearance of the steel. Each of these methods has its own advantages and is suitable for specific applications. The choice of coating method depends on factors such as the intended use of the steel billets, environmental conditions, and desired properties of the coating.

- Q: How is the quality of steel billets determined?

- The determination of steel billet quality involves a combination of physical and chemical tests, which are conducted to ensure that the steel meets the necessary standards and specifications for its intended use. Chemical analysis is a primary method employed to assess the quality of steel billets. This procedure involves testing the steel's composition to verify that it contains the appropriate levels of various elements, such as carbon, manganese, silicon, and others. The steel's chemical composition plays a critical role in determining its mechanical properties, such as strength, hardness, and more. In addition to chemical analysis, several physical tests are conducted to evaluate the quality of steel billets. These tests include measuring the dimensions, weight, and straightness of the billets to ensure they adhere to the specified tolerances. Surface inspections are also performed to detect any defects, like cracks, seams, or irregularities, that may impact the steel's performance. Mechanical tests are another vital aspect of determining steel billet quality. These tests assess the steel's mechanical properties, including strength, ductility, toughness, and hardness. Tensile tests are frequently conducted to determine the maximum load the steel billet can bear before breaking or deforming. Impact tests are also performed to evaluate the steel's ability to withstand sudden shocks or impacts. Additionally, non-destructive testing techniques are utilized to identify any internal defects or inconsistencies within the steel billets. These methods, such as ultrasonic testing, magnetic particle inspection, and radiographic testing, aid in ensuring that the steel is devoid of any hidden defects that could compromise its quality or structural integrity. Overall, the quality of steel billets is determined through a comprehensive evaluation involving chemical analysis, physical tests, mechanical tests, and non-destructive testing. These methods guarantee that the steel meets the necessary standards and specifications, providing assurance of its reliability and suitability for various applications.

- Q: What are the different surface treatments for corrosion resistance in steel billets?

- There are several surface treatments available for corrosion resistance in steel billets, including hot-dip galvanizing, electroplating, and mechanical plating. Hot-dip galvanizing involves immersing the steel billets in molten zinc, creating a protective layer that prevents corrosion. Electroplating uses an electric current to deposit a layer of metal, such as zinc or chromium, onto the surface of the billets. Mechanical plating involves tumbling the billets with metal powder, typically zinc, in a rotating drum to create a protective coating. Each of these treatments provides varying degrees of corrosion resistance and can be chosen based on specific requirements and budget constraints.

- Q: What is the role of steel billets in the construction of dams and reservoirs?

- The role of steel billets in dam and reservoir construction cannot be overstated. These semi-finished steel products are vital for manufacturing various components and structures necessary for the construction process. A primary application of steel billets in dam and reservoir construction is their use in producing reinforced concrete. Reinforced concrete combines the strength and durability of steel with the versatility and moldability of concrete. Steel billets are utilized to create steel reinforcement bars, commonly called rebars, which are embedded within the concrete to improve its tensile strength and prevent cracking when subjected to heavy loads. These rebars provide the necessary structural support for the dam or reservoir, ensuring its stability and long life. Furthermore, steel billets are essential for fabricating gates, penstocks, and other mechanical components required for dams and reservoirs. These components play a crucial role in regulating water flow, controlling water levels, and managing the release of water from the reservoir. Steel billets are forged, rolled, or machined to manufacture these specialized components, guaranteeing their strength, reliability, and resistance to corrosion. Moreover, steel billets are indispensable in constructing spillways, which are designed to safely discharge excess water from reservoirs during periods of heavy rainfall or floods. Spillway gates, channels, and other structures are often made from steel billets because they need to withstand high water pressure and turbulent flow conditions. To summarize, steel billets are vital in dam and reservoir construction. They are instrumental in producing reinforced concrete, thereby providing structural support and enhancing the overall strength of the structure. Steel billets are also used in the production of gates, penstocks, spillways, and other mechanical components, ensuring the efficient operation and long-term durability of these crucial water management infrastructures.

- Q: What are the main factors affecting the formability of stainless steel billets?

- The main factors affecting the formability of stainless steel billets include the composition of the steel, the temperature at which it is being formed, the grain size and structure of the material, and the amount of deformation applied during the forming process. Firstly, the composition of the stainless steel billet plays a crucial role in its formability. Different grades of stainless steel have varying amounts of alloying elements such as chromium, nickel, and molybdenum, which affect the material's mechanical properties. For example, higher levels of chromium can increase the material's resistance to corrosion but may reduce its formability. Therefore, the choice of stainless steel grade is essential to ensure optimal formability for a specific application. Secondly, the temperature at which the stainless steel billet is being formed influences its formability. Stainless steel exhibits better formability at elevated temperatures due to increased ductility. Heating the billet helps to reduce its yield strength and allows for easier deformation. However, excessive heating can lead to grain growth and reduced mechanical properties, so it is crucial to find the right balance between temperature and formability. The grain size and structure of the stainless steel billet also affect its formability. Fine-grained materials tend to exhibit better formability compared to coarse-grained ones. Finer grains allow for more uniform deformation and reduced likelihood of cracking or tearing during forming processes. Additionally, the presence of certain microstructural features, such as precipitates or twins, can also impact the formability of stainless steel billets. Lastly, the amount of deformation applied to the stainless steel billet during the forming process affects its formability. Excessive deformation can lead to strain hardening, causing the material to become less ductile and more prone to cracking. Therefore, it is essential to carefully control the amount and distribution of deformation to ensure optimal formability. In summary, the main factors affecting the formability of stainless steel billets include the composition of the steel, the temperature at which it is being formed, the grain size and structure of the material, and the amount of deformation applied during the forming process. Understanding and controlling these factors is crucial for achieving the desired formability and ensuring successful manufacturing of stainless steel components.

- Q: How are steel billets inspected for hardness?

- Steel billets are inspected for hardness using a non-destructive testing method called ultrasonic testing. This involves the use of high-frequency sound waves that are transmitted through the billet. The reflected sound waves are then analyzed to determine the hardness of the steel. This method allows for accurate and reliable hardness inspection without causing any damage to the billet.

- Q: Is the reaction of carbon and carbon dioxide a redox reaction?

- Is the redox reflect the oxidizing agent is CO2 C 2009-10-22, the reducing agent is the oxidizing agent is CO2, is C 2009-10-22 reductant is redox reaction. Price reduction in carbon dioxide carbonation, was reduced, so is the oxidant.

- Q: How is the quality of steel billets ensured during the manufacturing process?

- The quality of steel billets is ensured through a combination of rigorous testing and adherence to established industry standards throughout the manufacturing process. There are several key steps involved in ensuring the quality of steel billets: 1. Raw Material Inspection: The first step is to carefully inspect the raw materials, usually iron ore and/or scrap metal, to ensure they meet the required specifications. This includes checking for impurities and verifying the chemical composition. 2. Melting and Refining: The raw materials are then melted in a furnace, and any impurities are removed through refining processes such as desulphurization and degassing. This helps improve the quality of the steel by reducing unwanted elements and enhancing its overall purity. 3. Continuous Casting: Once the steel is refined, it is then cast into billet form using a continuous casting process. This process ensures a consistent size and shape of the billets, which is important for further processing. 4. Non-Destructive Testing: During and after the continuous casting process, various non-destructive testing techniques are employed to check the integrity of the billets. These include ultrasonic testing, magnetic particle inspection, and visual inspection, among others. These tests help identify any defects or imperfections that may compromise the quality of the billets. 5. Heat Treatment: Depending on the desired properties of the final steel product, the billets may undergo heat treatment processes such as annealing, quenching, or tempering. These processes further enhance the strength, hardness, and other mechanical properties of the steel. 6. Final Inspection: The finished steel billets undergo a final inspection to ensure they meet the required specifications. This includes checking their dimensions, surface quality, and mechanical properties. Samples from each batch are typically subjected to destructive testing to confirm their strength and other properties. 7. Traceability and Documentation: Throughout the manufacturing process, it is crucial to maintain proper traceability and documentation of all quality-related activities. This includes recording test results, maintaining batch records, and ensuring proper identification and labeling of the billets. By following these stringent procedures and conducting various tests, manufacturers can ensure that the quality of steel billets is maintained at every stage of the manufacturing process. This helps to guarantee that the final steel products made from these billets will meet the required standards and perform as intended in various applications.

- Q: Are steel billets used in the production of musical instruments?

- Yes, steel billets are used in the production of certain musical instruments. They are commonly used as a primary component in the manufacturing of steel-string acoustic guitars. The steel billets are typically shaped into a solid metal rod, which is then used to create the guitar's neck. This ensures that the instrument has the necessary strength and durability to withstand the tension of the steel strings. Additionally, steel billets can also be used in the production of other metal instruments such as drums or percussion instruments, where their strength and resilience are beneficial. However, it is important to note that the use of steel billets may vary depending on the specific instrument and its manufacturing process.

- Q: What are the main factors affecting the hardenability of stainless steel billets?

- The main factors affecting the hardenability of stainless steel billets are the chemical composition of the steel, the cooling rate during heat treatment, and the presence of alloying elements such as chromium, nickel, and molybdenum. The chemical composition determines the steel's ability to form martensite, a hard and brittle phase, during quenching. The cooling rate influences the transformation of austenite, the high-temperature phase, into martensite. Alloying elements enhance the hardenability by promoting the formation of martensite and improving the steel's ability to retain its hardness upon cooling.

Send your message to us

Q235/3SP 105MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords