Chrome Alloy Steel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chrome Alloy Steel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

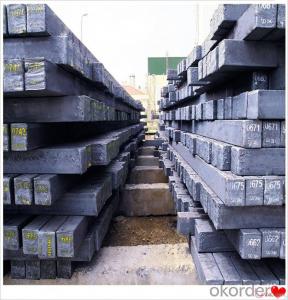

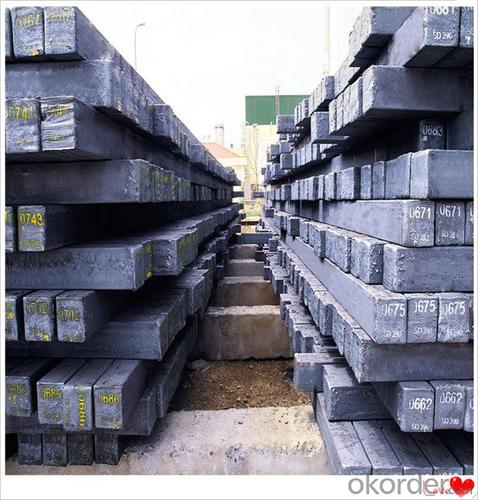

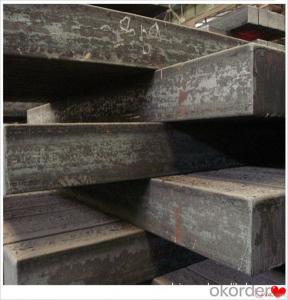

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: How are steel billets used in the manufacturing of structural steel?

- Steel billets are a crucial raw material in the manufacturing of structural steel. These billets, which are essentially semi-finished steel products, are typically produced through a process called continuous casting, where molten steel is solidified into a rectangular shape. Once the steel billets are formed, they are further processed in steel mills to create various structural steel products such as beams, columns, angles, and channels. The billets are heated and then passed through a series of rolling mills, where they undergo intense pressure and shaping to achieve the desired dimensions and profiles. During the rolling process, the steel billets are elongated and transformed into long, slender shapes. This is achieved by repeatedly passing the billets through a set of rollers, which gradually reduce their cross-sectional area. The rolling mills can be configured differently to produce different types of structural steel products, catering to specific construction requirements. After the rolling process, the structural steel products are further subjected to various finishing processes such as cooling, cutting, straightening, and surface treatment. These processes ensure that the final product meets the required specifications, including dimensional accuracy, surface quality, and mechanical properties. The use of steel billets in the manufacturing of structural steel offers several advantages. Firstly, the semi-finished nature of billets allows for flexibility in customization, enabling the production of steel products with different sizes, shapes, and profiles. Additionally, the continuous casting process used to produce billets ensures a more consistent and uniform material quality, reducing the risk of defects or inconsistencies in the final product. Overall, steel billets play a vital role in the manufacturing of structural steel by providing a reliable and versatile raw material. Their transformation through rolling and other processes allows for the production of high-quality, durable, and structurally sound steel products that are widely used in construction, infrastructure, and industrial applications.

- Q: How are steel billets used in the manufacturing of railway equipment?

- Steel billets are an essential component in the manufacturing of railway equipment. These billets, which are semi-finished steel products, are typically used as raw material for various railway components such as rails, wheels, axles, and other structural parts. To begin the manufacturing process, the steel billets are subjected to heating within a furnace to reach the desired temperature for hot rolling. This heating process helps to improve the malleability and ductility of the steel, making it easier to shape and form into the desired railway equipment components. Once the steel billets have reached the appropriate temperature, they are then passed through a series of rolling mills. During this stage, the billets are subjected to intense pressure, causing them to elongate and change their shape. This process is known as hot rolling and is crucial for transforming the steel billets into long, slender sections such as rails or axles. After hot rolling, the railway components are further processed to achieve the desired shape and specifications. For example, rails may undergo a process called head hardening to enhance their wear resistance and strength. Similarly, wheels and axles may undergo additional heat treatment processes to improve their mechanical properties and durability. It is important to note that the quality of the steel billets used in the manufacturing process plays a significant role in the overall quality of the railway equipment. The steel used should have specific characteristics such as high strength, toughness, and resistance to wear and fatigue, to ensure the safety and reliability of the final products. In summary, steel billets are an integral part of the manufacturing process for railway equipment. Through hot rolling and subsequent processing, these billets are transformed into various components that form the backbone of rail systems. The quality of the steel billets directly impacts the performance and longevity of the final railway equipment, making them a critical element in the industry.

- Q: What are the main factors affecting the thermal conductivity of steel billets?

- The thermal conductivity of steel billets is influenced primarily by several factors. Firstly, the chemical composition of the steel plays a crucial role in determining its thermal conductivity. Elements like carbon, manganese, and silicon can impact the crystal structure and atom arrangement within the steel, thereby affecting its ability to conduct heat. Generally, steels with higher carbon content have lower thermal conductivity due to increased impurities and non-conductive carbide formation. Secondly, the microstructure of the steel also affects its thermal conductivity. Heat conduction in steel happens through lattice vibrations called phonons. Grain boundaries, dislocations, and other defects within the microstructure can hinder phonon movement, resulting in reduced thermal conductivity. Conversely, a more uniform and fine-grained microstructure enhances thermal conductivity. Furthermore, the temperature of the steel billet significantly impacts its thermal conductivity. As the temperature rises, the thermal conductivity of steel generally decreases due to increased scattering of phonons by lattice vibrations and higher thermal resistance. Another factor influencing the thermal conductivity of steel billets is their physical dimensions, specifically cross-sectional area and length. A larger cross-sectional area leads to higher thermal conductivity as there is more space for heat transfer. Similarly, longer billets tend to have lower thermal conductivity due to increased distance for heat conduction. Lastly, the presence of impurities and alloying elements in the steel can also affect its thermal conductivity. For instance, alloying elements like nickel, chromium, and copper can alter the crystal structure and lattice vibrations, thereby influencing the thermal conductivity of the steel billet. In conclusion, the thermal conductivity of steel billets is influenced by factors such as chemical composition, microstructure, temperature, physical dimensions, and the presence of impurities and alloying elements. Understanding these factors is crucial in various industrial applications where heat transfer and thermal management are critical.

- Q: What are the common sizes and shapes of steel billets?

- Steel billets are typically manufactured in various sizes and shapes to cater to the diverse needs of different industries. The most common sizes of steel billets range from 100mm to 200mm in width and 100mm to 300mm in height. However, it is important to note that these dimensions can vary based on the specific requirements of the end-user or the steel manufacturer. In terms of shapes, steel billets are commonly produced in rectangular or square shapes. Rectangular billets have flat and smooth surfaces with four right angles, while square billets have equal sides with four right angles as well. These shapes are preferred because they facilitate easier handling, transportation, and further processing of the steel billets. Additionally, steel billets can also be produced in other shapes such as round, hexagonal, or octagonal, depending on the intended application. These non-traditional shapes are often utilized in specialized industries like automotive or aerospace manufacturing, where unique geometries are necessary to meet specific design requirements. It is worth mentioning that the sizes and shapes of steel billets can vary across different regions and industries, as each may have their own specific standards and preferences. Therefore, it is important for manufacturers and end-users to communicate and align their requirements to ensure the production of steel billets that meet their respective needs.

- Q: How are steel billets used in the manufacturing of railway wagons?

- Steel billets are used in the manufacturing of railway wagons as they serve as the raw material for various components such as frames, side panels, and undercarriages. These billets are first heated and then shaped into the desired form through processes like rolling or forging. The resulting components are strong, durable, and able to withstand the rigorous demands of railway transportation, ensuring the safety and reliability of the wagons.

- Q: What is the difference between carbon three plants and carbon four plants?

- Also known as C4 plants. Such as corn, sugar cane, sorghum, amaranth and so on.CO2 is the first product of the assimilation of photosynthetic carbon cycle in three carbon compounds 3- phosphoglycerate plants, known as carbon three plants (C3 plants), such as wheat, soybeans, cotton, tobacco, etc.. C3 plants have higher CO2 compensation points than C4 plants, so the survival rate of C3 plants is lower than that of C4 plants when the CO2 content is low.By contrast, the division of C3 plant cells is less definite than that of C4 plants, and CO2 uses less efficiently. To some extent, C3 plants may be considered as prokaryotes in plants, whereas C4 plants are more like eukaryotes".

- Q: How are steel billets used in the production of oil and gas components?

- Steel billets are an essential component in the production of oil and gas components due to their strength, durability, and ability to withstand extreme conditions. These billets are used as raw materials in various manufacturing processes to create various equipment and parts required in the oil and gas industry. One common application of steel billets in oil and gas production is in the manufacturing of pipes and casings. These billets are heated and then rolled or forged into seamless or welded pipes, which are used for transporting oil and gas from wells to refineries or distribution centers. The high strength of steel billets ensures that these pipes can withstand the high pressure and corrosive nature of the substances being transported. Steel billets are also used in the production of valves, flanges, and fittings that are critical components in oil and gas infrastructure. These billets are machined or forged into various shapes and sizes to create these components, which are used to control the flow of oil and gas within the pipelines or at different stages of the production process. The durability and resistance to corrosion of steel billets make them ideal for these applications, as they can withstand the harsh conditions often encountered in oil and gas operations. Furthermore, steel billets are utilized in the production of drilling equipment such as drill bits, drill collars, and drill pipes. These billets are often treated with heat or alloying elements to enhance their strength and wear resistance. The resulting components are capable of withstanding the intense forces and abrasion encountered during drilling operations, ensuring efficient and reliable extraction of oil and gas reserves. Overall, steel billets play a vital role in the oil and gas industry by providing the necessary raw materials to manufacture durable and high-performance components. Their strength, durability, and resistance to corrosion make them an ideal choice for the challenging conditions encountered in the production, transportation, and processing of oil and gas.

- Q: Billet prices skyrocketing weekend, Southern China steel prices rose?

- So, three month contract period, even transportation during two days, there will be a big money and lose big reversal.

- Q: Can steel billets be used in the production of mining equipment?

- Steel billets, being semi-finished products, find extensive use in the manufacturing industry for the production of mining equipment. The robustness and durability of steel make it an ideal material for mining equipment, which often operates in tough and demanding conditions. By processing and shaping steel billets, essential components like gears, shafts, frames, and buckets can be created, all of which are vital for mining equipment. Moreover, steel billets can be easily welded, machined, and heat-treated to meet the specific requirements and standards of mining equipment. Therefore, steel billets play a critical role in ensuring the strength and dependability necessary for safe and efficient mining operations.

- Q: What is Alfa carbon? What is beta carbon?

- Alfa is directly connected with the functional groups of carbon atoms of carbon atoms, such as CH3CH2COOH CH2 in which methylene propionate is Alfa carbon carbon carbon atom is the beta carbon atom is directly connected with the functional groups and the connection of the carbon (around Kazakhstan), such as the CH3CH2COOH CH3 propionic acid methyl carbon is the beta carbon

Send your message to us

Chrome Alloy Steel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords